For any inquiries or concerns regarding our equipment, service, parts, pricing, and locations, kindly reach out to us through any of the following channels. We would be delighted to assist you in any way we can.

35

Years in Business

78,426

Machines Built

ONE STOP SHOP PACKAGING EQUIPMENT

Accutek manufactures a wide variety of filling equipment to fill most product types into a wide assortment of container types. Our filling machines utilize the latest technologies to achieve the highest speeds and most accurately filled bottles on the market. Accutek filling machines can accommodate regular free flowing liquid products, products that are very viscous or thick, products that tend to foam, products that string or drip, products that have particulates or chunks, and dry products. We manufacture six different styles of filling systems: Auger Fillers, Overflow Fillers, Piston Fillers, Positive Displacement Fillers, Timed Flow Volumetric Fillers, and Vacuum Fillers. Our filling machinery is available from a single head bench top filler for low speed filling all the way up to a high speed 60 head rotary filling system.

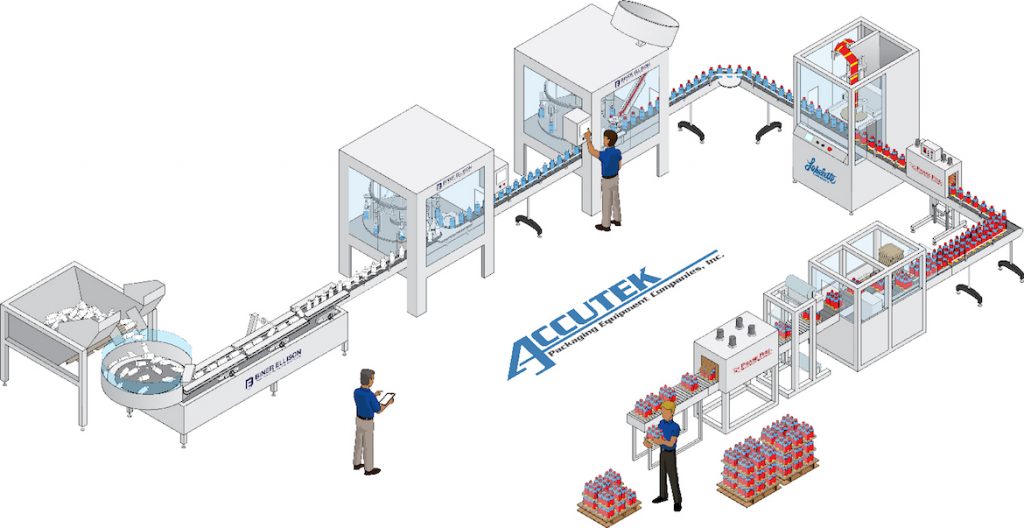

Accutek Packaging Equipment Companies, Inc. is one of the largest packaging machinery manufacturers in the United States . It is a leading developer and manufacturer of complete turnkey packaging solutions. The Accutek Packaging Equipment Companies offer a wide variety of filling machines, capping machines, labeling machines, and complete packaging systems. Other equipment manufactured by the Accutek companies includes: bottle unscramblers, bottle rinsers and washers, sleeve labeling machines, tamper evident neck banders, heat tunnels, heat and induction sealing machines, inkjet and laser date coders, conveyors, turntables, and support packaging machinery.

Labelette SL Shrink Sleeve Labelers have flexible film shrink sleeve labels placed onto bottles using a sleeve applicator or sleeve labeler. The sleeves are then held in place by shrinking them using hot air or steam from a heat tunnel. Labelette manufactures a variety of shrink sleeve labelers / sleeve applicators and heat tunnels for both full body sleeve labeling and tamper evident bands. Sleeve Labeling and Safety Sleeve Banding Machines are a new addition to the Labelette line of products. These items were added to the Labelette brand with the acquisition of American Packaging Products and its line of sleeve labeling equipment and Phase Fire heat tunnels. Labelette’s Labeling Ma ...

Many large businesses are already reaping the benefits of a commercial solar installation. These innovative companies are defining the way future businesses will incorporate solar energy and are showing how it is a good fiscal decision. Here are some major global companies that have made the switch to solar including: Target, Apple, Macy’s, Intel, and Ikea. As green energy becomes more prevalent, many corporations are leading the way to a greener future. Accutek has joined these businesses in adopting solar energy after realizing there are tremendous benefits to be gained. The expense of solar equipment is dropping as technology becomes more advanced, enabling us to take advantage of t ...

Accutek Packaging Equipment Companies, Inc., one of the largest packaging machinery manufacturers in the United States, is a leading developer and manufacturer of complete packaging solutions. Accutek Packaging Equipment Companies offer a wide variety of bottle filling, capping, and labeling machines. We pride ourselves on being able to support startup companies that need economical semi-automatic bottle fillers. We also have the depth of experience needed to service mature companies with world-class technology, providing automatic packaging lines at competitive prices. Custom options Each customer has unique product and container combinations. We routinely customize our machines to acco ...

In the face of the Covid-19 pandemic there is an opportunity to provide personal and hard surface disinfecting products to the public. Accutek can rapidly supply liquid fillers to the disinfectant packaging industry. Hand sanitizer is moderately thicker than water making it ideally suited for piston fillers. The Accutek AVF series fillers can fill up to twelve containers at a time. Switching from filling two, eight or sixteen ounce containers can be done in minutes without tools. Accutek overflow fillers, the APOF series, are well suited for filling, ethyl alcohol another key component in preventing the spread of disease. Changing between container sizes with the APOF can also be accompl ...

The backbone of every packaging line is the conveyor system that moves the product through the various stages of the production process. Typically, the product sits on a moving belt to get from point A to point B, but occasionally it is necessary to have access to the top or bottom of a container, a bottomless conveyor solves this requirement. A bottomless conveyor suspends a container between two moving belts. Versatility The Accutek bottomless conveyor is one of our most adaptable products capable of being used in several different ways. Raise one end or the other of the gripper belts to change line height or extract a container from a puck. Pucks are used to stabilize a rounded conta ...

Accutek is the leading supplier of packaging equipment and machines in the world. With hundreds of machine designs we meet our customer’s needs for complete inline filling systems. We have been serving the packaging industry for thirty years and have acquired an amazing amount of expertise in packaging machine design and manufacture. The first small packaging machine produced by Accutek was a timed flow liquid filler. Packaging Machines Thirty years ago, packaging machines were not nearly as flexible as they are today. Timing and control were accomplished mechanically and with a few relays. Accutek was an industry leader in the transition to programable electronics operating pneumatic ...

The Accutek bottomless conveyor is one of our most versatile, best selling and low cost machines we manufacture. This machine in most cases is available to be completed and put into shipping in less than one business day. Bottomless conveyors are used to provide a smooth and stable transfer of containers up to 2 ½ gallons between machines or around corners, allowing access to the bottom of a container. Allowing access to the bottom of containers is required, when it used in conjunction with an ink jet or laser coding machine applying date and lot coding. Accutek bottomless conveyors are compatible with most ink jet and laser coding machines. The bottomless conveyor can also be used when ...

Listen Listen to the sound of your conveyor as it is working. Hear the sound of the conveyor plates as they roll over the pulleys. You should not hear bearing noise or gear noise. The sound of conveyor operation should remain at the same volume over time. Any new noise that you hear from your conveyor is an indication that something may be wrong. Don’t ignore the noise find its cause. Look Look at the surface of the belt for build up of spilled product on the surface of the belt and accumulation of gunk between the conveyor links. Keep your conveyor free of foreign material for good performance. Cleaning The conveyor belt must be loosened and removed for proper cleaning. The conveyor ...

304 Stainless Steel The most common form of 304 stainless steel is 18-8, or 18/8, stainless steel, which contains 18 percent chromium and 8 percent nickel. 304 can withstand corrosion from most oxidizing acids. That durability makes 304 easy to sanitize, and therefore ideal for kitchen and food handling applications. However, 304 stainless steel is susceptible to corrosion from chloride solutions, or from saline food products. Chloride ions can create localized areas of corrosion, called “pitting,” which can spread beneath protective chromium barrier. Solutions with as little as 25 ppm of sodium chloride can begin to have a corrosive effect. 316 Stainless Steel 316 grade is the secon ...

Accutek Packaging Equipment Companies are delighted to announce the expansion of the business to a 130,000 sq. ft building in Vista, California. This is due to consistent growth in the packaging industry where we are one of the leading developers and manufacturers of quality packaging machinery, including complete turnkey packaging solutions. The new location will be a great place to meet prospects, deliver high-quality packaging equipment and enable us to respond effectively to the growing needs of our various customers that are seeking to implement technology-oriented solutions in their business. This new location will feature technical packaging equipment expertise with an in-house ...

Finding the Best Liquid Filling Equipment for Your Needs Here are factors that should be considered when searching for the correct bottling machinery for your liquid filling line. Liquid filling machinery selection is driven by your product characteristics, viscosity being the primary metric. Peanut butter is put in a bottle by a liquid filling machine, as is acetone. Peanut butter and acetone are both liquids but at opposite ends of the viscosity range. The bottling machinery needed to move peanut butter into a bottle is very different than the liquid filling machinery used for acetone. Liquid Filler Technologies There are four different liquid filler technologies, piston, timed flow, ...

Happy Thanksgiving Accutek Packaging Equipment will be closed on Thursday, November 22nd and Friday, November 23rd in observance of Thanksgiving Day. We will reopen on Monday, November 26th with normal business hours. ...

Your manufacturing process is stable, and you have packaging that is working for you in your competitive retail environment. Sales has forecast a massive increase in sales requiring you to triple your manufacturing capacity. It’s a good thing, but how are you going to do that? You reach out to the sales engineering staff at Accutek and they propose a suite of packaging machines from Accutek that will do what you need. An application engineer needs to know the nature of your product and the volume of business you wish to support. The physical characteristics of your product determine the type of filling machine needed. Is your product a liquid and what is its viscosity at ambient temper ...

Accurate level inspection of filled and sealed containers is a major issue for bottling industry quality management systems. Fill level variance is often specified by consumer protection agency regulations that cannot be ignored. These same regulations address the need for secure closures to prevent tampering or product contamination. Containers on the shelf must also be cosmetically perfect. Labels that are wrinkled, tilted or out of position cannot be tolerated in a competitive retail environment. Checking each container for fill level, closure integrity, and labeling issues is a challenge. Current bottling lines process as many as 200 containers a minute. There are four different issu ...

A system of conveyors does add value to your plant and does more than move product through your plant. A conveyor system properly executed will make your processes operate with efficiency and minimum down time The operating efficiency and long-term strategy of the factory, warehouse or distribution center can be compromised by utilizing the wrong conveyor type (or sometimes even the right type applied incorrectly) negatively impacting profitability and/or competitive advantage. Considerations Before specifying a conveyor system, you must know the maximum dimensions and weight of the material you are going to move. How far are you moving the material and the interface requirements of the ...