Most packaging lines do not lose throughput during a stop.

They lose it during the restart.

In many U.S. facilities, engineers focus on reducing downtime duration. The goal is to get the machine running again as fast as possible.

But restart speed and restart stability are not the same thing.

A fast restart can destabilize the entire line.

The Restart Assumption

The common belief is simple:

“If we reduce downtime, throughput improves.”

That belief ignores what happens in the first 10 seconds after motion resumes.

During restart:

- Conveyors accelerate

- Fill heads re-synchronize

- Capping torque stabilizes

- Labels re-index

- Accumulation zones rebalance

If these events are not coordinated, the line enters a temporary instability window.

Repeated restart instability reduces sustained output.

Where the Breakdown Occurs

Restart instability typically appears as:

- Sudden container compression

- Temporary downstream starvation

- Torque spikes

- Label misalignment

- Brief reject cycles

These are rarely logged as major faults.

They are absorbed as performance loss.

Over hundreds of cycles, that loss compounds.

Restart Ramp Profile and System Effect

| Restart Profile | Immediate Effect | Line Stability Outcome |

|---|---|---|

| Instant full speed | Rapid compression | Shock wave transfer |

| Uneven machine ramp | Speed mismatch | Spacing distortion |

| Delayed downstream ramp | Starvation risk | Rhythm disruption |

| Controlled synchronized ramp | Gradual spacing recovery | Stable restart |

Restart behavior is a control architecture issue.

Not just a motor issue.

Why Faster Is Not Always Better

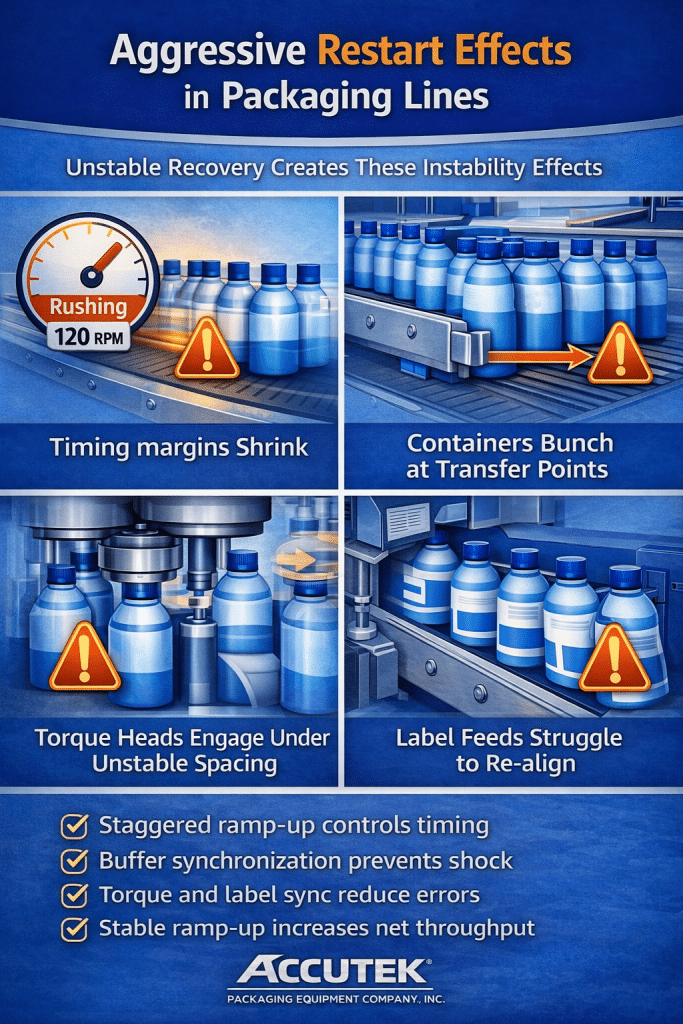

When machines accelerate too quickly:

- Timing margins shrink

- Containers bunch at transfer points

- Torque heads engage under unstable spacing

- Label feeds struggle to re-align

The line looks operational.

But it is not yet stable.

Each unstable restart increases the probability of micro-stops within the next few minutes.

The Hidden Cost of Aggressive Recovery

In U.S. plants with high throughput targets, operators are often rewarded for minimizing downtime duration.

This can encourage aggressive ramp settings.

The result is:

- Short downtime

- Followed by 30–60 seconds of unstable production

- Followed by small corrective pauses

The downtime metric improves.

The throughput metric does not.

Restart Synchronization Variables

| Variable | What Changes During Restart | Stability Impact |

|---|---|---|

| Conveyor acceleration rate | Spacing compression | Transfer shock |

| Filler speed ramp | Fill timing drift | Weight variation |

| Capper torque stabilization | Torque overshoot | Reject increase |

| Label re-index timing | Alignment shift | Cosmetic defects |

These variables must move together.

If one machine reaches operating speed before another, imbalance occurs.

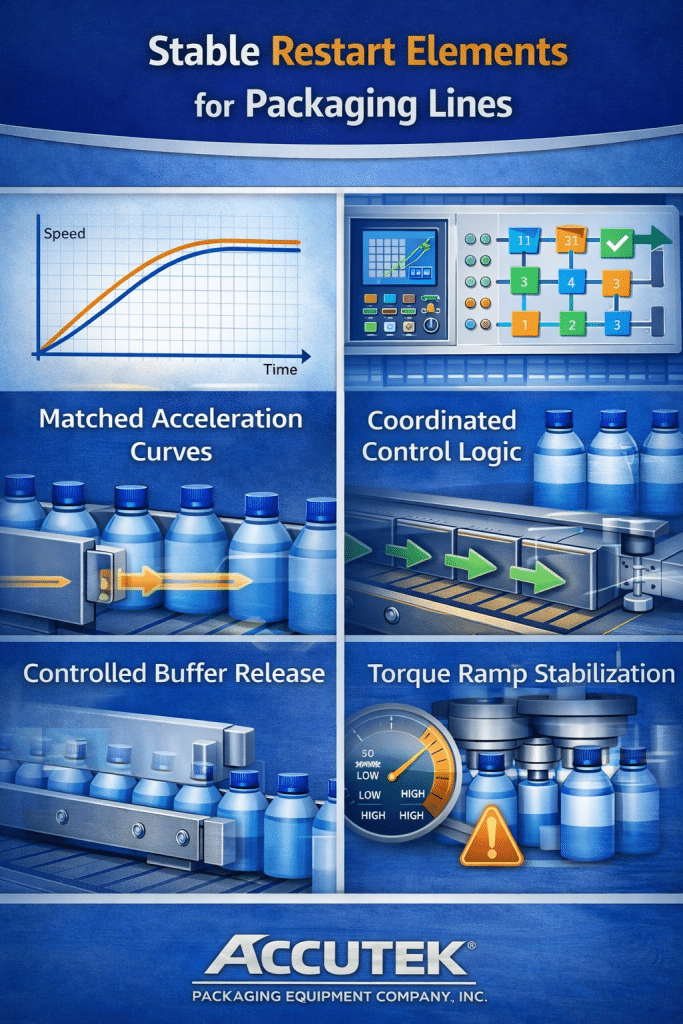

Engineering Repair: Designing Stable Restarts

Stable restart design requires:

- Matched acceleration curves

- Coordinated control logic

- Controlled buffer release

- Torque ramp stabilization

Modern integrated systems allow restart sequencing instead of simultaneous acceleration.

Accutek Packaging Equipment engineers filling, capping, and labeling systems with coordinated ramp logic so that mechanical speed increases do not outpace downstream readiness. When restart behavior is designed as a system event rather than a machine event, instability drops significantly.

Integration reduces restart shock.

Restart Behavior vs Sustained Throughput

| Restart Strategy | Downtime Duration | Sustained Throughput Impact |

|---|---|---|

| Maximum acceleration | Short stop time | Higher instability |

| Manual recovery | Variable restart | Inconsistent flow |

| Sequenced ramp-up | Slightly longer restart | Stable sustained rate |

| Synchronized control restart | Controlled recovery | Higher net output |

Throughput is not measured at the moment of restart.

It is measured across the full shift.

Stable restart behavior often produces higher total output than aggressive acceleration.

Explaining It Clearly

Imagine traffic stopped at a red light.

If every car floors the accelerator at the same moment, traffic compresses and spreads unevenly.

If cars accelerate in sequence with spacing control, flow stabilizes quickly.

Packaging lines behave the same way.

Restart coordination determines whether the line flows smoothly or oscillates.

Why This Matters in U.S. Manufacturing

American facilities face:

- Tight production schedules

- High labor costs

- Strict quality requirements

- Limited downtime tolerance

Unstable restarts increase:

- Rework

- Rejects

- Short corrective stops

- Operator intervention

Stability during restart protects throughput across the entire shift.

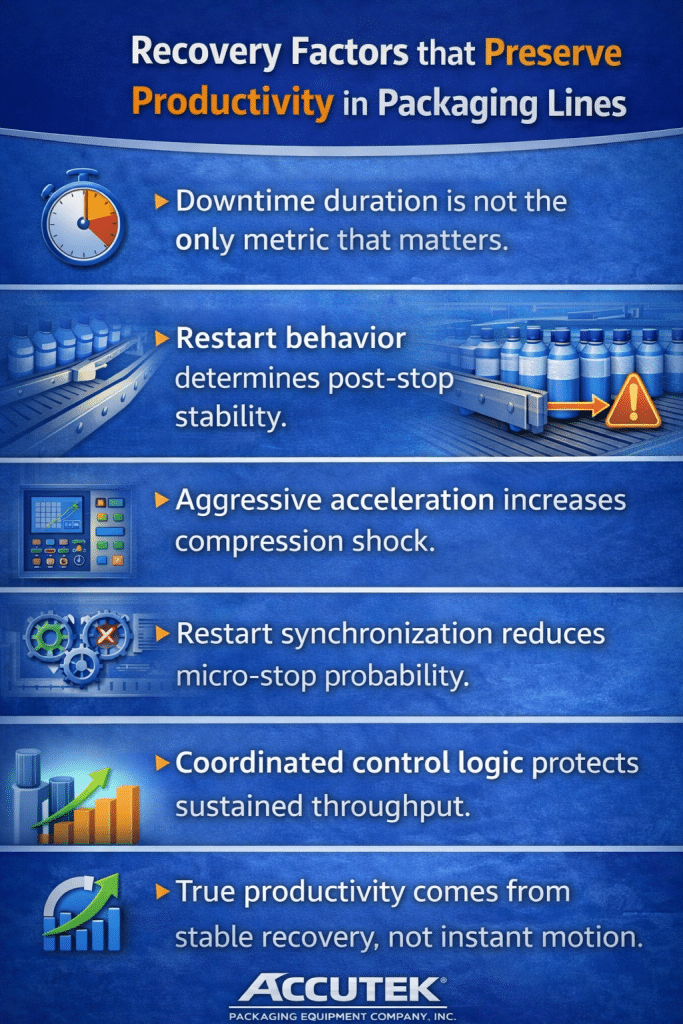

Final Perspective

- Downtime duration is not the only metric that matters.

- Restart behavior determines post-stop stability.

- Aggressive acceleration increases compression shock.

- Restart synchronization reduces micro-stop probability.

- Coordinated control logic protects sustained throughput.

- True productivity comes from stable recovery, not instant motion.

For more details contact us:

| California | Texas | Florida |

|---|---|---|

| Address: 2980 Scott St, Vista, CA 92081 | Address: 8051 Jetstar Dr #175, Irving, TX 75063 | Address: 14231 Jetport Loop W #1, Fort Myers, FL 33913 |

| Phone: (760) 734-4177 | Phone: (972) 915-6888 | Phone: (239) 225-4020 |

| Fax: (760) 734-4188 | Fax: (971) 915-6999 | Fax: (239) 225-4024 |

| Hours: 8:00 AM – 4:30 PM | Hours: 8:00 AM – 4:30 PM | Hours: 8:00 AM – 4:30 PM |