When it comes to packaging, the quality of your product is only as good as the seal that protects it.

Even the best formulas, ingredients, or manufacturing practices can’t compensate for a weak or inconsistent cap. A loose, leaky, or improperly sealed container can lead to contamination, spills, and shortened shelf life—problems that can affect product quality and damage brand reputation.

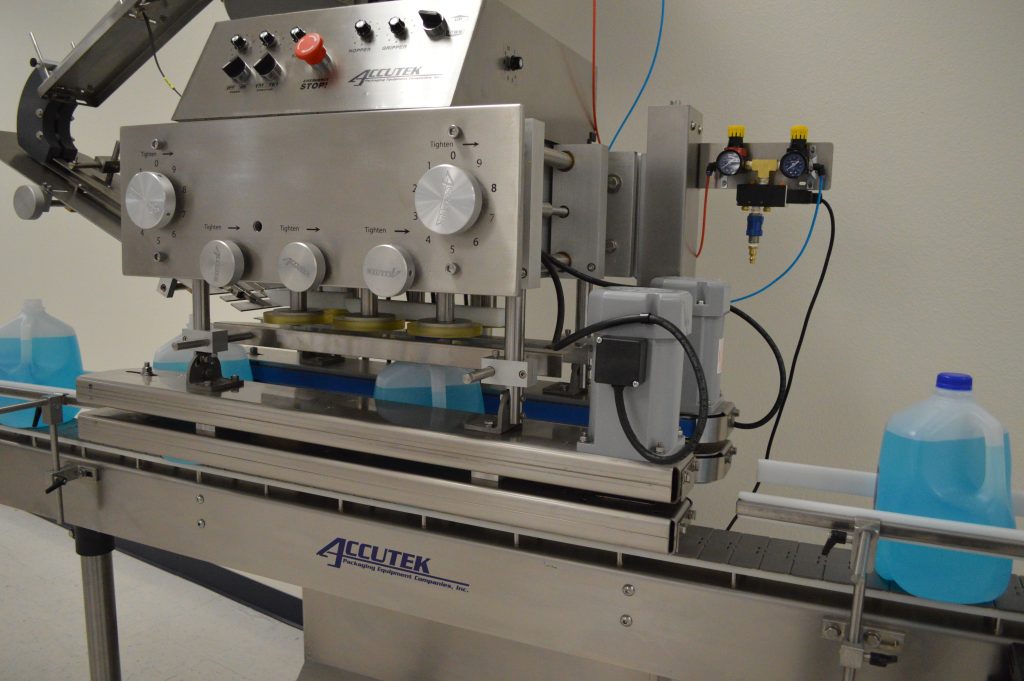

That’s why investing in a reliable capping machine is one of the most important decisions any manufacturer can make. At Accutek Packaging Equipment, we understand that product safety starts at the cap—and our advanced capper are designed to ensure every container is sealed securely, consistently, and efficiently.

How Capping Affects Product Safety

A properly applied cap creates a protective barrier between the product and its immediate environment. Whether you’re packaging food, beverages, pharmaceuticals, or cosmetics, caps keep out anything that can degrade product quality.

Poorly applied caps can result in:

- Leaks and spills, which waste product and create potentially unsafe messes.

- Contamination, ruining food and pharmaceutical products.

- Shorter shelf life thanks to oxygen and bacteria entering the containers.

- Consumer complaints and recalls, harming your brand’s reputation and bottom line.

Cappers remove these risks by applying caps with the right amount of torque. The caps create a tight, secure seal, but not so tight that the cap or container becomes damaged.

The Role of Torque Control and Consistency

In the world of capping machines, torque control is everything. Torque is the rotational force used to tighten a cap onto a container. If torque levels are inconsistent, the seal may vary from one product to the next. That variability can lead to leaks, broken caps, or insufficient sealing—all of which compromise safety and shelf life.

Accutek’s automated capping machines are engineered with precise torque control systems that apply uniform pressure across every container. Whether you’re sealing bottles, jars, or tubes, our machines ensure consistent, repeatable results that maintain product integrity throughout storage and transport.

Modern systems, such as servo-driven cappers and mechanical clutch designs, also provide easy torque adjustments, allowing you to fine-tune performance for different cap styles and materials.

How Reliable Capping Machines Extend Shelf Life

A strong, airtight seal plays a major role in preserving freshness and extending a product’s shelf life. Here’s how:

- Properly capped containers prevent air from entering, which slows oxidation and spoilage.

- Secure seals block bacteria, moisture, and dust from compromising the product.

- For carbonated drinks, chemicals, or pharmaceuticals, consistent sealing ensures performance and stability.

- Products stay safe and sellable for longer periods, minimizing losses due to spoilage or returns.

By ensuring every container is capped correctly, manufacturers can maintain the same level of quality on day 90 as on day one.

Integration with Filling and Packaging Machines

A capper doesn’t operate in isolation—it’s part of a larger packaging machine system that includes filling machines, conveyors, and labelers. When integrated properly, these machines create a continuous packaging flow where each step complements the next.

For example, Accutek’s filling and capping systems work together to ensure smooth transitions between filling and sealing. The result is a packaging line that not only runs faster but also maintains higher quality and reliability from start to finish.

Seal It Right, Every Time

Your product’s safety, freshness, and quality depend on one simple factor: a reliable seal. With Accutek’s cappers, you can rest assured that every container leaving your facility meets the highest standards for consistency and protection.

Invest in the equipment that safeguards your brand and your customers. Contact Accutek Packaging Equipment today to learn how our filling and capping machines can help you deliver perfectly sealed, longer-lasting products every time.