In modern manufacturing, labeling is no longer a simple finishing step. It plays a critical role in brand presentation, regulatory compliance, and production efficiency. Accutek’s Automatic Pressure-Sensitive Labeling Systems are designed to meet these demands by delivering consistent accuracy, speed, and flexibility for U.S. manufacturers.

This article explains how pressure-sensitive labeling systems work, where they fit in a packaging line, and why Accutek’s approach makes them a preferred solution across multiple industries.

What Is an Automatic Pressure-Sensitive Labeling System?

A pressure-sensitive labeling system applies labels that already have adhesive on the back. When the label contacts the container and light pressure is applied, it bonds securely—no heat, glue, or water is required.

Automatic pressure-sensitive labelers operate inline and continuously, allowing manufacturers to label products at production speed with minimal operator involvement.

These systems are widely used because they:

- Support a wide range of container shapes

- Provide clean, precise label placement

- Adapt easily to different label designs and SKUs

How Accutek’s Automatic Labeling Systems Operate

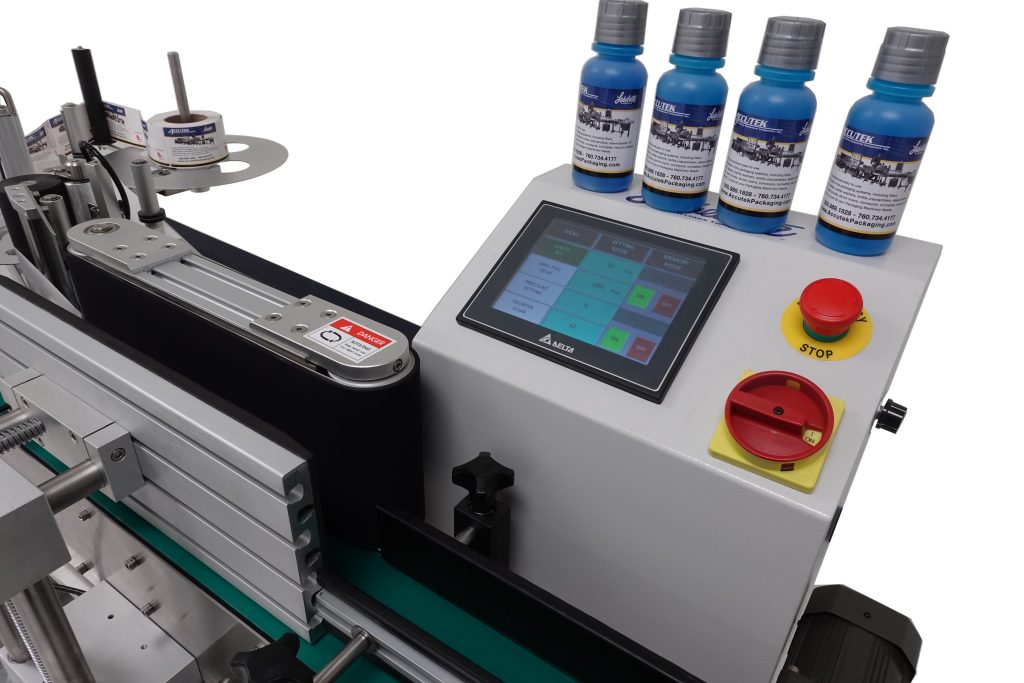

Accutek designs its pressure-sensitive labeling machines to integrate seamlessly with filling, capping, and conveying equipment.

Step-by-Step Process

1. Container Infeed

Containers are fed into the labeling station via conveyor and guided into position.

2. Product Detection

Sensors detect each container and trigger the label application process at the correct moment.

3. Label Application

The label applicator dispenses and applies the label in sync with conveyor movement, ensuring consistent placement on every container.

4. Discharge and Line Continuation

Once labeled, containers exit the station and move to the next stage of packaging.

This automated process reduces human error, improves consistency, and supports higher production volumes.

Key Benefits of Pressure-Sensitive Labeling

Automatic pressure-sensitive labeling systems offer several operational advantages:

| Benefit | Why It Matters |

|---|---|

| High Accuracy | Consistent label placement improves appearance and compliance |

| Production Speed | Supports continuous, high-throughput packaging lines |

| Versatility | Handles round, flat, and uniquely shaped containers |

| Fast Changeovers | Easy adjustments for different labels and products |

| Reduced Waste | Precise application minimizes label rejects |

Where Pressure-Sensitive Labelers Fit in a Packaging Line

Pressure-sensitive labelers are typically positioned after filling and capping operations:

- Filling Machine

- Capping Machine

- Pressure-Sensitive Labeling System

- Inspection or Rejection Station

- Packing or Cartoning

Accutek engineers its labeling machines to work smoothly within this sequence, helping manufacturers avoid bottlenecks and inefficiencies.

Pressure-Sensitive Labeling vs Other Labeling Methods

| Labeling Method | Typical Use | Key Advantage |

|---|---|---|

| Pressure-Sensitive | Most consumer products | Fast and highly adaptable |

| Shrink Sleeve | Full-body branding | 360-degree coverage |

| Hot Melt Glue | Irregular surfaces | Strong adhesion |

| Blow-On / Tamp | Specialty applications | Precise placement |

Pressure-sensitive labeling remains the most widely adopted option due to its flexibility and efficiency.

Why Manufacturers Choose Accutek Labeling Systems

Accutek’s pressure-sensitive labeling machines stand out because they are:

- Engineered in the USA for durability and production reliability

- Designed for integration with Accutek filling and capping machines

- Scalable, supporting small batches to higher-volume operations

- Backed by domestic support, parts availability, and service expertise

Rather than offering a one-size-fits-all solution, Accutek customizes labeling systems to match real production needs.

Industries That Benefit From Accutek Labeling Machines

Accutek pressure-sensitive labeling systems are commonly used in:

- Food and beverage manufacturing

- Cosmetics and personal care

- Pharmaceutical and nutraceutical production

- Chemical and household products

Their ability to handle multiple container types and label designs makes them suitable across diverse industries.

Who Should Consider an Automatic Pressure-Sensitive Labeler?

These systems are ideal for manufacturers that:

- Run medium to high-volume production lines

- Manage multiple SKUs and frequent label changes

- Require consistent label quality and placement

- Want long-term reliability with U.S.-based support

Final Perspective

Automatic pressure-sensitive labeling systems are a core component of efficient packaging lines. When properly engineered and supported, they help manufacturers improve throughput, reduce waste, and maintain professional product presentation.

Accutek’s automatic pressure-sensitive labeling systems combine precision engineering, scalability, and domestic support—making them a dependable choice for manufacturers seeking long-term labeling performance.