Labeling plays a critical role in food and beverage manufacturing. Beyond branding, labels communicate compliance information, product identity, and consumer trust. However, labeling in this industry is uniquely complex due to container variety, environmental conditions, and high production demands.

Understanding the most common labeling challenges—and how they are addressed through proper equipment design—can significantly improve efficiency, quality, and consistency on the production floor.

Why Labeling Is More Challenging in Food & Beverage Production

Food and beverage packaging introduces variables not commonly found in other industries. Containers are often exposed to temperature fluctuations, moisture, and residue, all while moving at high speeds.

Key contributing factors include:

- Wide variety of container shapes and materials

- Cold-fill or hot-fill environments

- Condensation on bottles and jars

- High-speed production requirements

- Regulatory labeling requirements (nutrition, traceability, compliance)

These conditions create unique labeling challenges that require more than basic equipment adjustments.

Common Labeling Challenges in Food & Beverage Production

1. Label Slippage on Cold or Wet Containers

Why it happens:

Condensation or moisture reduces adhesive bonding strength, causing labels to slide or peel during application.

Why it matters:

Poor adhesion leads to rejected products and inconsistent branding.

2. Wrinkling and Air Bubbles

Why it happens:

Uneven pressure, flexible packaging, or inconsistent rotation can trap air beneath the label.

Why it matters:

Wrinkled labels reduce shelf appeal and create quality control issues.

3. Misalignment on Cylindrical or Irregular Containers

Why it happens:

Inconsistent container tracking or unstable movement during labeling.

Why it matters:

Misaligned labels reduce visual consistency and may violate labeling standards.

3. Misalignment on Cylindrical or Irregular Containers

Why it happens:

Inconsistent container tracking or unstable movement during labeling.

Why it matters:

Misaligned labels reduce visual consistency and may violate labeling standards.

4. Smudging or Damage to Printed Information

Why it happens:

Excessive friction, guide contact, or aggressive handling during labeling.

Why it matters:

Smudged dates or ingredient lists can cause regulatory and recall risks.

5. Changeover Downtime Between Products

Why it happens:

Manual adjustments and non-repeatable settings slow transitions between SKUs.

Why it matters:

Increased downtime reduces throughput and production efficiency.

How These Challenges Are Typically Solved

Modern labeling solutions address these challenges through engineering rather than operator intervention.

Key Engineering Approaches

| Challenge Area | Engineering Solution |

|---|---|

| Container instability | Controlled guides and synchronized conveyors |

| Label adhesion issues | Consistent pressure and wrap control |

| Alignment problems | Precision container tracking |

| Surface damage | Reduced contact and smooth material transitions |

| Changeover delays | Adjustable and repeatable settings |

These principles form the foundation of modern food and beverage labeling systems.

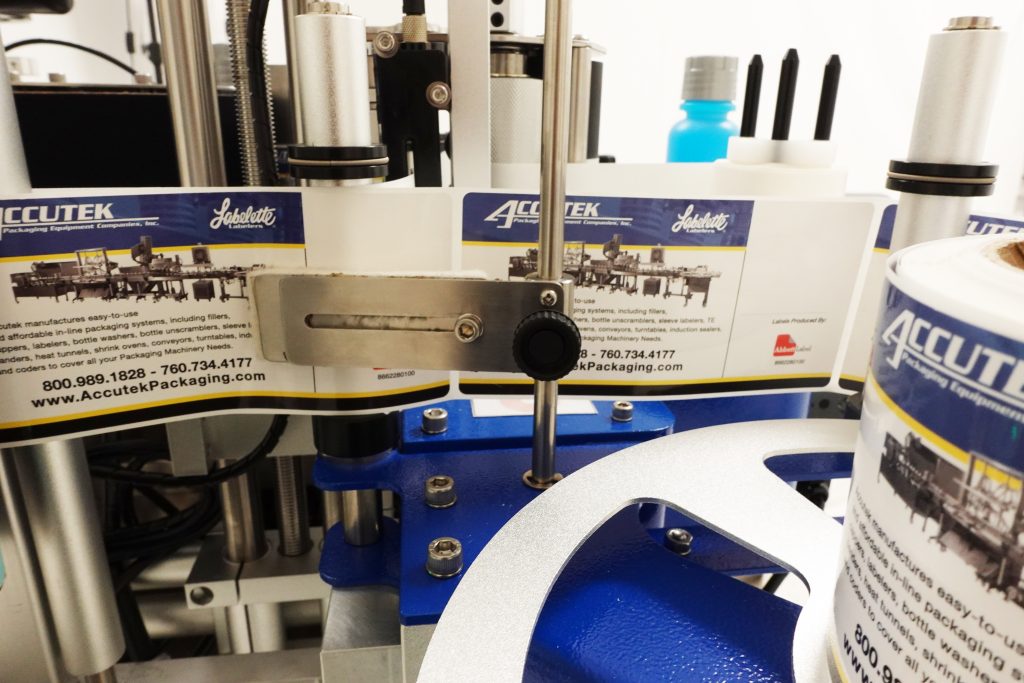

How Accutek Labeling Systems Address These Challenges

Accutek designs labeling equipment with a focus on process control, adaptability, and long-term reliability—qualities essential for food and beverage production environments.

Rather than relying on rigid mechanical force, Accutek systems emphasize controlled movement, consistent tension, and stability across varying container types.

Core Design Considerations

| Design Focus | Operational Benefit |

|---|---|

| Controlled container handling | Reduced movement and misalignment |

| Precision label application | Cleaner, more accurate labeling |

| Adjustable guides and tooling | Faster changeovers |

| Modular system design | Easier integration into existing lines |

Operational Impact Across the Production Line

Properly engineered labeling systems contribute to measurable improvements across operations.

Performance Impact Table

| Operational Area | Improvement Observed |

|---|---|

| Label accuracy | Consistent placement across runs |

| Waste reduction | Fewer rejected containers |

| Throughput | More stable line speeds |

| Maintenance | Predictable service intervals |

| Product appearance | Higher shelf consistency |

Where Labeling Fits Within a Food & Beverage Packaging Line

Labeling is most effective when integrated smoothly with upstream and downstream processes.

Typical Packaging Line Flow

| Production Stage | Equipment Type |

|---|---|

| Filling | Gravity, piston, or volumetric fillers |

| Capping | Spindle or chuck cappers |

| Labeling | Pressure-sensitive labeling systems |

| Inspection | Vision or manual checks |

| Accumulation | Rotary or inline tables |

This integration ensures steady product flow and minimizes handling-related issues.

Final Perspective

- Labeling challenges in food and beverage production are complex but manageable

- Many issues stem from inconsistent container handling and environmental factors

- Engineering-driven labeling systems significantly reduce defects and downtime

- Controlled motion, precise application, and adaptability are critical to success

- The right labeling approach improves efficiency, compliance, and brand presentation

When labeling systems are designed with real production conditions in mind, manufacturers can maintain quality while scaling operations confidently.