Packaging machinery decisions are rarely reversible—and the wrong choice can quietly drain millions from a manufacturing operation over time. From chronic downtime and labor inefficiencies to quality failures and forced re-investment, most packaging losses do not come from machine breakdowns. They come from selection mistakes made long before equipment is installed.

Manufacturers in food, beverage, cosmetics, pharmaceuticals, and chemicals face increasing pressure to scale faster, meet compliance requirements, and maintain consistent output. Yet many still approach machinery selection as a purchasing exercise rather than an engineering decision.

This article breaks down the most expensive packaging machinery selection mistakes and explains how manufacturers can avoid them through smarter evaluation, system-level thinking, and engineering-led planning.

Mistake #1: Buying for Speed Instead of Throughput

One of the most common—and costly—errors is selecting packaging machinery based solely on maximum rated speed.

Machine brochures highlight bottles per minute. Real-world production exposes a different metric: sustained throughput.

Why this mistake is expensive

- High-speed machines amplify upstream and downstream weaknesses

- Minor jams cause cascading line stoppages

- Operators slow machines down to maintain stability

Speed vs Throughput Reality

| Selection Focus | What Buyers Expect | What Actually Happens |

|---|---|---|

| Maximum BPM | Faster output | Increased downtime |

| Isolated machine speed | Higher capacity | Line imbalance |

| Peak performance | Production gains | Operator intervention |

| Minimal evaluation | Lower upfront cost | Higher long-term losses |

How to avoid it:

Evaluate packaging machinery as part of a balanced line, not as a standalone speed upgrade.

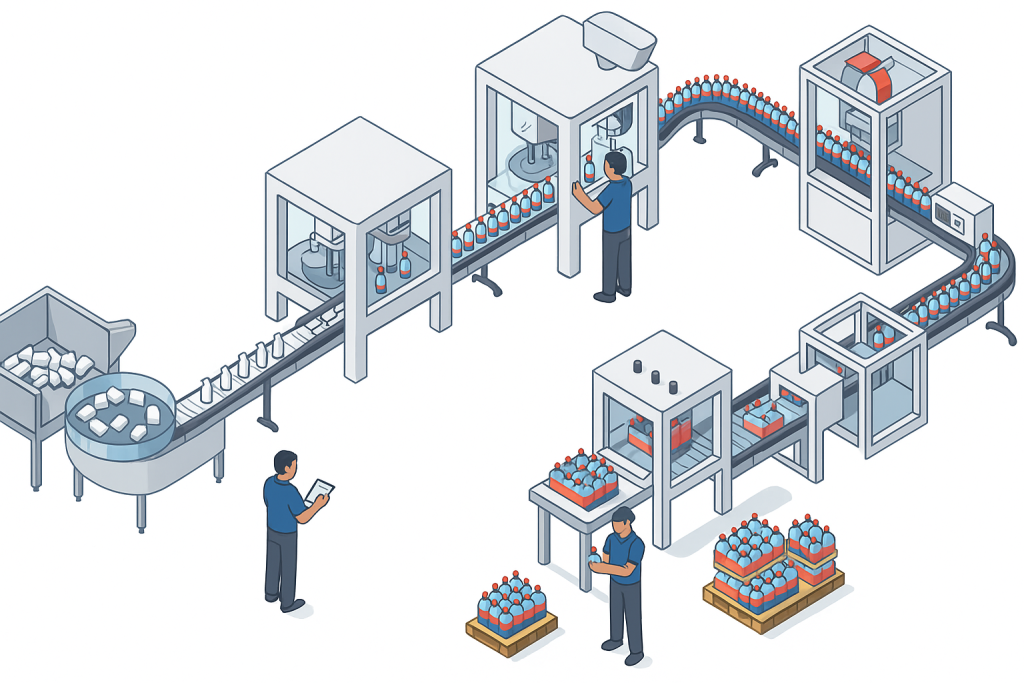

Mistake #2: Treating Filling, Capping, and Labeling as Separate Purchases

Many manufacturers source filling machines, cappers, and labelers independently—often from different suppliers. While this may reduce upfront cost, it introduces integration risk that compounds over time.

Where costs accumulate

- Conveyor mismatch and backpressure issues

- Inconsistent machine communication

- Increased changeover time

- Multiple service vendors and spare parts inventories

Integrated vs Fragmented Line Impact

| Factor | Fragmented Line | Integrated System |

|---|---|---|

| Line synchronization | Manual | Engineered |

| Downtime recovery | Slow | Predictable |

| Changeovers | Labor-heavy | Streamlined |

| Long-term scalability | Limited | Designed-in |

How to avoid it:

Select packaging machinery with system-level engineering compatibility, even if machines are purchased in phases.

Mistake #3: Ignoring Product & Container Variability

Packaging machinery that performs well on one SKU can struggle—or fail—when products change.

Common overlooked variables include:

- Viscosity changes across product lines

- Foaming or aeration

- Container tolerances

- Label material variation

Cost of ignoring variability

- Excessive scrap

- Rework and relabeling

- Lost production during adjustments

- Premature equipment replacement

Product-Driven Selection Checklist

| Variable | Must Be Evaluated At Selection Stage |

|---|---|

| Viscosity range | ✔ |

| Foaming behavior | ✔ |

| Container geometry | ✔ |

| Closure torque tolerance | ✔ |

| Label material & adhesive | ✔ |

How to avoid it:

Match machinery mechanics and controls to the most demanding product—not the easiest one.

Mistake #4: Underestimating Changeovers and SKU Expansion

Changeovers are one of the largest hidden costs in packaging operations.

Manufacturers often focus on:

- Output rate

- Capital cost

…and ignore:

- Time to switch containers

- Tooling adjustments

- Calibration requirements

Why this becomes expensive

- Lost production hours

- Increased labor dependency

- Inconsistent quality during transitions

Changeover Cost Impact

| Changeover Type | Typical Time | Annual Cost Impact |

|---|---|---|

| Manual tooling | 45–90 min | High |

| Semi-tool-less | 20–40 min | Moderate |

| Engineered quick-change | 5–15 min | Controlled |

How to avoid it:

Evaluate packaging machinery based on changeover design, not just steady-state operation.

Mistake #5: Buying for Today Instead of the Next 5–10 Years

Short-term thinking is one of the most expensive mistakes manufacturers make.

Common symptoms:

- Equipment maxed out within 18–24 months

- Forced line replacement instead of expansion

- Inability to add automation later

Scalability Evaluation Framework

| Question | Risk If Ignored |

|---|---|

| Can capacity be increased without replacement? | High |

| Are controls expandable? | Medium |

| Can automation be added later? | High |

| Is service support long-term? | High |

How to avoid it:

Select packaging machinery with modular design, expandable controls, and proven long-term support.

Mistake #6: Prioritizing Purchase Price Over Lifecycle Cost

Lower upfront cost often hides higher operating expense.

True cost drivers buyers overlook

- Downtime frequency

- Spare parts availability

- Service response time

- Operator training requirements

Total Cost of Ownership Comparison

| Cost Area | Low-Cost Machine | Engineered System |

|---|---|---|

| Purchase price | Lower | Higher |

| Downtime losses | Higher | Lower |

| Maintenance | Reactive | Predictable |

| Useful life | Shorter | Longer |

How to avoid it:

Evaluate total cost of ownership, not just acquisition cost.

How Manufacturers Avoid These Mistakes in Practice

Manufacturers that consistently avoid costly machinery decisions follow three principles:

- Engineering-first evaluation, not sales-driven selection

- System-level thinking across filling, capping, and labeling

- Long-term scalability planning, not short-term fixes

This is why manufacturers increasingly gravitate toward suppliers with deep engineering expertise, integrated system design capability, and long-term service support—such as Accutek Packaging Equipment Company, Inc., whose equipment portfolios are engineered to work together rather than compete for line stability.

Key Takeaways: Avoiding Million-Dollar Packaging Machinery Mistakes

- Speed without balance reduces real throughput

- Fragmented machinery creates hidden integration costs

- Product variability must drive machine selection

- Changeover design directly impacts profitability

- Scalability must be engineered, not assumed

- Lifecycle cost matters more than purchase price

Manufacturers that treat packaging machinery as a long-term production system, rather than a short-term equipment purchase, protect margins, uptime, and growth potential.