Choosing the right packaging machinery is no longer just about speed or price. For growing manufacturers, the decision between a standard and a customized machinery solution can directly affect throughput, changeover efficiency, compliance, and long-term scalability.

While standard machines offer faster deployment and lower upfront costs, customization can unlock operational advantages that off-the-shelf equipment cannot deliver—especially for manufacturers dealing with multiple SKUs, unique containers, or strict regulatory requirements.

This article breaks down the real engineering, operational, and financial trade-offs between standard and customized packaging machines to help manufacturers make informed, future-proof decisions.

What Defines a Standard Packaging Machine?

It is a pre-configured system designed to accommodate common container sizes, label formats, and production speeds. These machines are built for broad market use and typically ship with fixed mechanical layouts and predefined adjustment ranges.

Where Standard Models Perform Well

- Single or limited product lines

- Stable container dimensions

- Predictable production volumes

- Faster installation timelines

It is often ideal for manufacturers entering automation for the first time or operating within narrowly defined production parameters.

What Custom Packaging Machinery Really Means

Customized packaging machinery goes beyond cosmetic changes. It involves engineering modifications that adapt the machine’s mechanics, controls, and integration points to a manufacturer’s specific production realities.

Customization may include:

- Container-specific handling components

- Adjustable or servo-driven changeover systems

- Integrated inspection, rejection, or vision modules

- Line-level synchronization with upstream and downstream equipment

Rather than forcing production to adapt to the machine, customization allows the machine to adapt to production.

Core Trade-Offs: Customization vs. Standard Models

| Evaluation Factor | Standard | Customized |

|---|---|---|

| Initial Cost | Lower upfront investment | Higher initial engineering cost |

| Deployment Speed | Faster installation | Longer lead time due to design |

| Flexibility | Limited adjustment range | Designed for SKU and format diversity |

| Changeover Efficiency | Manual or semi-manual | Engineered for fast, repeatable changeovers |

| Long-Term Scalability | Often constrained | Built to scale with production growth |

This comparison highlights a common pattern: standard machines optimize for speed to purchase, while custom machines optimize for speed to operate.

Operational Impact Over Time

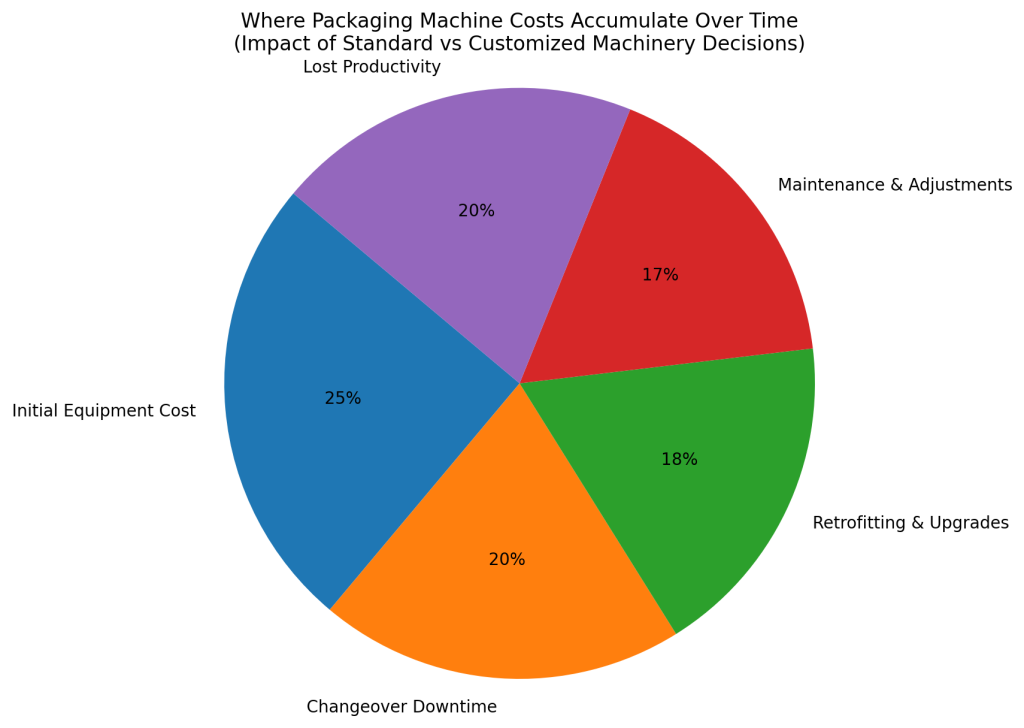

Many manufacturers underestimate how packaging machinery decisions compound over years of operation.

Hidden Costs of Standard Models

- Increased downtime during format changes

- Manual adjustments leading to inconsistency

- Retrofitting expenses as production evolves

- Reduced OEE as complexity increases

Advantages of Engineered Customization

- Stable performance across product variations

- Reduced operator dependency

- Predictable maintenance schedules

- Easier line expansions without full replacement

When Standard Packaging Machinery Makes Sense

Standard packaging machines remain the right choice when:

- Production requirements are unlikely to change

- Only one container type is used

- Regulatory complexity is minimal

- Budget constraints outweigh long-term flexibility

For startups or single-SKU manufacturers, standard packaging machinery can provide an efficient entry point into automation.

When Custom Packaging Machines Become the Better Investment

Customization becomes strategically valuable when:

- Multiple SKUs share the same line

- Containers vary in shape, material, or stability

- Branding requires precise label placement

- Growth plans include higher speeds or automation upgrades

In these scenarios, customization often reduces total cost of ownership despite higher upfront investment.

Customization vs. Standard: Decision Matrix

| Manufacturing Scenario | Recommended Approach |

|---|---|

| Single product, low volume | Standard packaging machine |

| Multiple SKUs, shared line | Customized packaging machinery |

| Rapid product launches | Custom changeover engineering |

| Long-term growth forecast | Modular customization |

| Strict quality tolerances | Engineered customization |

Key Takeaways for Manufacturers

- Standard packaging machines reduce time-to-purchase but can limit long-term flexibility

- Customized packaging machinery aligns equipment with real production conditions

- The right choice depends on SKU diversity, growth plans, and operational complexity

- Engineering-driven customization often lowers total cost of ownership over time

- Forward-looking machinery decisions prevent costly replacements later