For California manufacturers, packaging machine purchases carry added risk. Regulatory scrutiny, strict safety requirements, diverse product lines, and compressed production schedules leave little margin for equipment that is not fully production-ready at delivery.

Factory testing exists to reduce that risk—but many buyers misunderstand what factory testing should actually validate.

In packaging machinery, factory testing means verifying that a machine or complete packaging line performs correctly with real production variables before it ships to the customer’s facility. For California buyers, this step is critical to protecting startup timelines, regulatory compliance, and operational stability.

This article explains what effective factory testing includes, where expectations often break down, and how California manufacturers can use factory testing to avoid costly installation surprises.

Why Factory Testing Is Especially Critical for California Manufacturers

California production environments often combine:

- High SKU diversity

- Strict labeling and safety requirements

- Audits and inspections

- Tight customer delivery schedules

When packaging machines arrive untested under realistic conditions, problems are discovered during installation—when downtime is most expensive and regulatory pressure is highest.

For California buyers, weak factory testing increases the risk of:

- Missed production deadlines

- Compliance issues during inspections

- Extended commissioning and troubleshooting

- Unexpected engineering modifications on site

Factory testing is the last controlled opportunity to verify performance before equipment becomes part of a regulated production environment.

Where Buyer Expectations Commonly Break Down

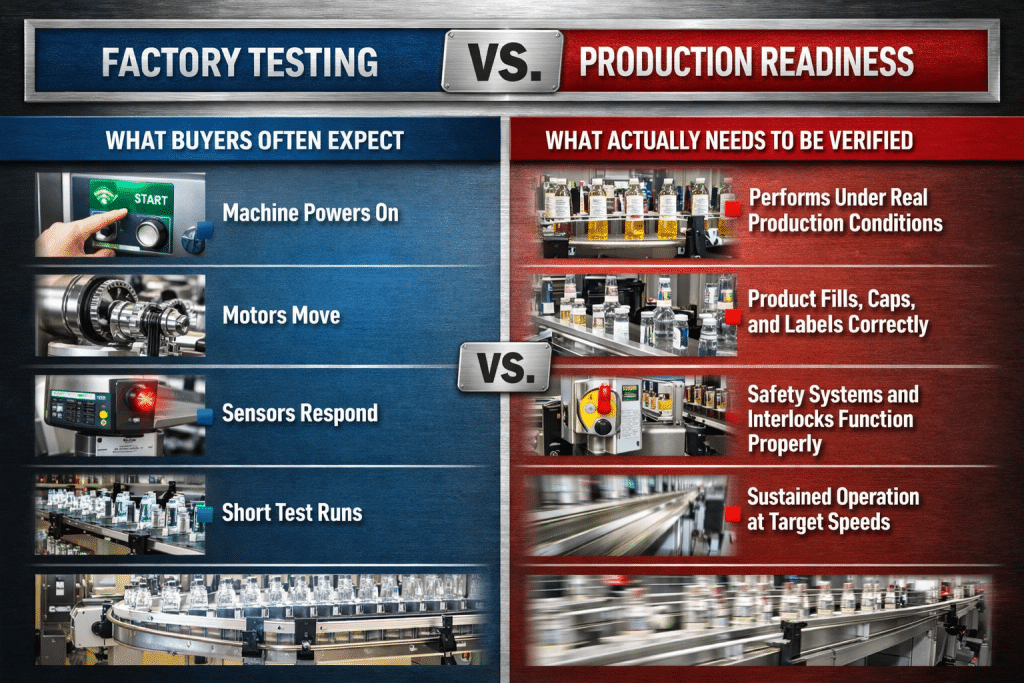

Many buyers assume that factory testing simply means the machine runs before shipment. That assumption leads to serious gaps in validation.

Factory Testing vs. Production Readiness

What Effective Factory Testing Should Include for California Buyers

Proper factory testing evaluates how the packaging machine behaves under the same constraints it will face in production.

1. Product, Container, and Closure Validation

Machines should be tested using:

- Actual or equivalent containers

- Real product or validated simulants

- Intended closures and label materials

This verifies:

- Fill accuracy and consistency

- Cap torque and seal integrity

- Label adhesion and placement under real conditions

These factors directly affect regulatory labeling accuracy and consumer safety.

What Effective Factory Testing Should Include for California Buyers

Proper factory testing evaluates how the packaging machine behaves under the same constraints it will face in production.

1. Product, Container, and Closure Validation

Machines should be tested using:

- Actual or equivalent containers

- Real product or validated simulants

- Intended closures and label materials

This verifies:

- Fill accuracy and consistency

- Cap torque and seal integrity

- Label adhesion and placement under real conditions

These factors directly affect regulatory labeling accuracy and consumer safety.

3. Safety and Compliance System Verification

Safety validation is not optional for California facilities.

Factory testing should verify:

- Emergency stop response

- Guarding and interlocks

- Fault detection and alarms

- Restart logic after stoppages

These systems must function properly before the machine enters a regulated workplace.

Where Factory Testing Often Fails to Protect Buyers

Factory testing loses value when it is reduced to a brief demonstration rather than structured validation.

Common Testing Gaps and Their Impact

| Missing Test Area | Risk to California Buyers |

|---|---|

| No product testing | Filling or sealing failures discovered during audits |

| No extended runtime | Heat and vibration issues appear during production |

| No changeover simulation | Long downtime when switching SKUs |

| No operator involvement | Training delays after installation |

When testing is incomplete, the customer’s facility becomes the test environment—where mistakes cost far more.

How Factory Testing Reduces Installation and Compliance Risk

Strong factory testing allows:

- Mechanical and control adjustments before shipment

- Baseline performance documentation

- Faster site acceptance testing

- Shorter time to validated production

For California manufacturers, this directly supports:

- Faster audit readiness

- Lower installation labor

- More predictable production scheduling

Factory testing shifts risk away from the plant floor and back into controlled engineering environments.

What California Buyers Should Actively Request During Factory Testing

Buyers should treat factory testing as an acceptance checkpoint, not a courtesy preview.

California manufacturers should request:

- Testing with real packaging machine components

- Operation at intended line speeds

- Demonstration of changeovers where applicable

- Measurement of fill accuracy and labeling quality

- Verification of safety and fault responses

These steps ensure the packaging machine is validated not only mechanically, but operationally.

Factory Testing Explained Simply

Think of factory testing as proving the machine can do your job, not just its job.

A machine may run perfectly in isolation, but if it cannot:

- Handle your containers

- Process your product

- Maintain speed without faults

- Meet safety expectations

then it is not production-ready.

For California manufacturers, skipping meaningful factory testing is like skipping inspection before opening a new facility. The risk doesn’t disappear—it just moves to the most expensive stage of the project.

What Factory Testing Should Deliver to California Buyers

- Confirms compatibility with real products and packaging machine materials

- Validates performance at production speeds

- Verifies safety and control systems before installation

- Reduces startup delays and commissioning risk

- Supports faster compliance readiness and audit preparation

For California buyers, factory testing is not a formality—it is a critical safeguard that protects production schedules, compliance obligations, and capital investment.