Across California’s processing and packaging sector, many plants run sophisticated packaging equipment yet still battle unpredictable stoppages, uneven performance, and recurring troubleshooting cycles. Lines may look modern and capable, but day-to-day behavior often feels fragile rather than robust.

The most common culprit is not worn hardware or poor maintenance. It is the control architecture — the rules that govern how machines communicate, how decisions are made, and how the line responds to disturbance. When control logic is fragmented or loosely coordinated, minor hiccups snowball into chronic instability that erodes productivity over time.

This article explores why control architecture quietly shapes long-term reliability, how weak designs create hidden operational risk in California facilities, and what differentiates resilient, future-ready packaging systems from brittle ones that require constant firefighting.

Why Control Design Carries Extra Weight in California Operations

Packaging operations in California operate under conditions that magnify the consequences of weak controls:

- Elevated labor costs make every minute of downtime expensive

- Compliance expectations demand repeatability, traceability, and documentation

- Rapid SKU proliferation requires frequent reconfiguration

- Sustainability targets heighten sensitivity to scrap and rework

Under these pressures, disconnected machine controls are not merely inconvenient — they are a structural liability. When control layers are aligned, lines behave predictably; when they are not, even premium packaging equipment struggles to deliver consistent results.

How Fragmented Controls Create System Fragility

Many lines evolve incrementally. A new filler is added one year, a labeler the next, then a coder or inspection unit later. Each arrives with its own controller, interface, and logic structure. Individually they perform well; collectively they often do not.

Typical warning signs include:

- Operators “herding” speeds across multiple stations

- Restart behavior that varies from shift to shift

- Alarm floods that confuse rather than clarify

- Extended recovery after even minor disruptions

The result is a line that appears functional but behaves erratically under real production conditions.

Operational Symptoms vs Control Root Causes

| What teams experience | What it’s usually blamed on | More likely control issue |

|---|---|---|

| Frequent resets | Mechanical defect | Poor inter-machine communication |

| Shifting line speeds | Operator inconsistency | No unified speed reference |

| Conflicting alarms | Maintenance backlog | Uncoordinated fault logic |

| Long recovery windows | Training gaps | No system-level restart sequence |

These are not packaging equipment failures — they are architectural failures.

What Robust Control Architecture Actually Looks Like

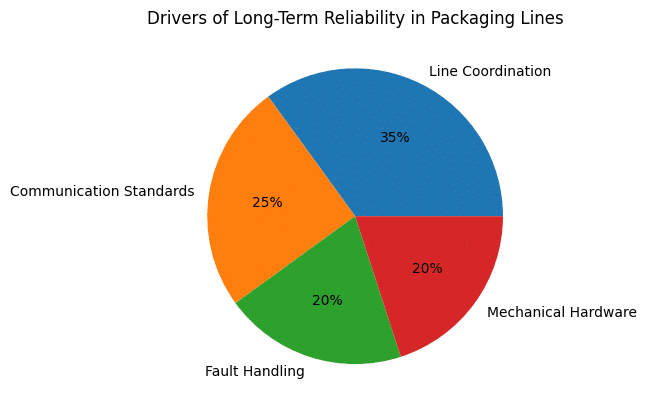

A dependable packaging system treats the entire line as a coordinated organism rather than a collection of independent devices. Three principles are critical.

1) Supervisory coordination

A higher-level control layer harmonizes starts, stops, speeds, and recovery behavior. Individual machine controllers still run their equipment, but they act in service of the whole line.

2) Common communication language

Machines exchange data through consistent, standardized protocols rather than ad-hoc wiring or proprietary links. This simplifies troubleshooting and future upgrades.

3) Structured fault response

Instead of chaotic shutdowns, the line follows clear decision paths — stopping safely, preserving product flow where possible, and restarting in a controlled sequence.

When these elements are in place, day-to-day operation becomes calmer and more predictable.

How Control Architecture Shapes OEE Outcomes

Even mechanically excellent packaging machines can deliver poor OEE if controls are weak. Architecture influences all three OEE pillars simultaneously.

Control design vs OEE impact

| Control weakness | Availability effect | Performance effect | Quality effect |

|---|---|---|---|

| No central speed reference | More stoppages | Forced slowdowns | Inconsistent output |

| Poor fault alignment | Longer downtime | Uneven ramp-up | Startup defects |

| No coordinated restart | Extended recovery | Unstable transitions | Higher scrap |

Strong architecture raises all three metrics together rather than trading one off against another.

Why Lines Become More Fragile Over Time

Most packaging systems do not begin unstable — they drift into instability as they grow.

A common pattern in California plants looks like this:

- A new machine is added to boost capacity

- Integration is handled quickly with basic signaling

- More equipment is layered in over years

- Control complexity accumulates without redesign

- The line becomes harder to diagnose and less predictable

Eventually, chronic quirks feel “normal,” even though they are avoidable.

How Accutek Approaches Control Architecture in California

Accutek Packaging Equipment treats control integration as a foundational design decision rather than a late-stage add-on.

Core priorities include:

- Consistent communication standards across all equipment

- Line-wide speed coordination instead of manual balancing

- Fault logic that prevents cascading failures

- Repeatable restart behavior that protects product quality

Accutek control design priorities

| Control domain | Design objective | What plants experience |

|---|---|---|

| Line coordination | One shared speed framework | Fewer unplanned stops |

| Communication | Standard protocols | Easier future upgrades |

| Fault strategy | Predictable shutdowns | Faster recovery |

| Restart sequencing | Coordinated ramp-up | Less scrap after restarts |

This approach helps California operations remain stable as they scale.

Why Controls Matter More Than Hardware for Longevity

Motors wear out. Valves need replacement. Belts stretch. Those realities are inevitable.

What endures is behavior — how machines interact, how the line reacts to disturbance, and how easily new equipment can be integrated. Control architecture determines that behavior.

A line with modest mechanical complexity but strong controls can outperform a more expensive line with weak coordination. Reliability is built into logic as much as into steel.

Designing Lines That Can Evolve

California manufacturers must plan for constant change: new products, higher volumes, and tighter regulations. Modern control architecture should enable:

- Adding new machines without redesigning the entire system

- Upgrading software without destabilizing production

- Expanding automation while preserving stability

When controls are thoughtfully designed, growth becomes manageable rather than disruptive.

Key takeaways

- Control architecture often matters more than mechanical design

- Fragmented controls create hidden reliability risks

- Strong architecture improves availability, performance, and quality together

- Instability usually grows gradually, not overnight

- System-level control design protects long-term production in California facilities