For manufacturers of creams, pastes, and viscous products, accurate and efficient filling is critical. Inconsistent fill volumes can lead to product waste, regulatory issues, and reduced production efficiency. The Accutek AVF Series Automatic Piston Filler provides a reliable, high-precision solution designed specifically for viscous liquids, creams, and pastes, offering manufacturers a turnkey filling system that meets both production and compliance needs.

Why Pharmaceutical, Cosmetic, and Food Manufacturers Choose Piston Filling Technology

Automatic piston fillers are designed to handle thick liquids and pastes where other filling technologies, like gravity or overflow fillers, are inadequate. Piston fillers uses a precision-driven piston and cylinder system to deliver consistent product volumes, reduce spillage, and minimize product waste.

Key advantages include:

- Precise and repeatable dosing

- Minimal foaming for viscous products

- Flexibility across multiple container sizes

- Compatibility with capping and labeling systems

Key Benefits of the Accutek AVF Series

The AVF Series is engineered for high-performance, low-maintenance, and maximum production efficiency.

| Benefit | Why It Matters |

|---|---|

| High Precision Filling | Ensures consistent product volume and quality, reducing waste. |

| Versatile Viscosity Handling | Works efficiently with creams, gels, pastes, and other thick liquids. |

| Scalable Production | Adjustable speed and volume settings support small and high-volume lines. |

| Sanitary Design | Stainless steel construction with easy cleaning supports cGMP compliance. |

| Integration Ready | Connects seamlessly to cappers, labelers, and conveyors for turnkey lines. |

Features That Make the AVF Series Stand Out

1. Adjustable Filling Volume

- Handles a wide range of container sizes, from small jars to large tubs

- Rapid changeover between SKUs reduces downtime

2. Programmable Automation

- Multiple fill programs for different product viscosities

- Digital controls provide precise monitoring and adjustments

3. High-Speed Operation

- Optimized for both small-batch and high-volume production

- Minimizes bottlenecks in fast-paced production lines

4. Compliance-Ready Design

- FDA-approved stainless steel construction

- Easy disassembly for cleaning and sanitation

- Meets cGMP standards for regulated industries

Industries That Benefit from the AVF Series

The AVF Series is ideal for:

- Cosmetics: Creams, lotions, gels, ointments

- Pharmaceuticals: Topical medications, gels, and salves

- Food Products: Nut butters, pastes, and sauces

- Chemicals: Adhesives, gels, and viscous liquids

Its flexibility allows manufacturers to use one machine for multiple product types, improving ROI and operational efficiency.

How Buyers Compare Piston Filling Machines

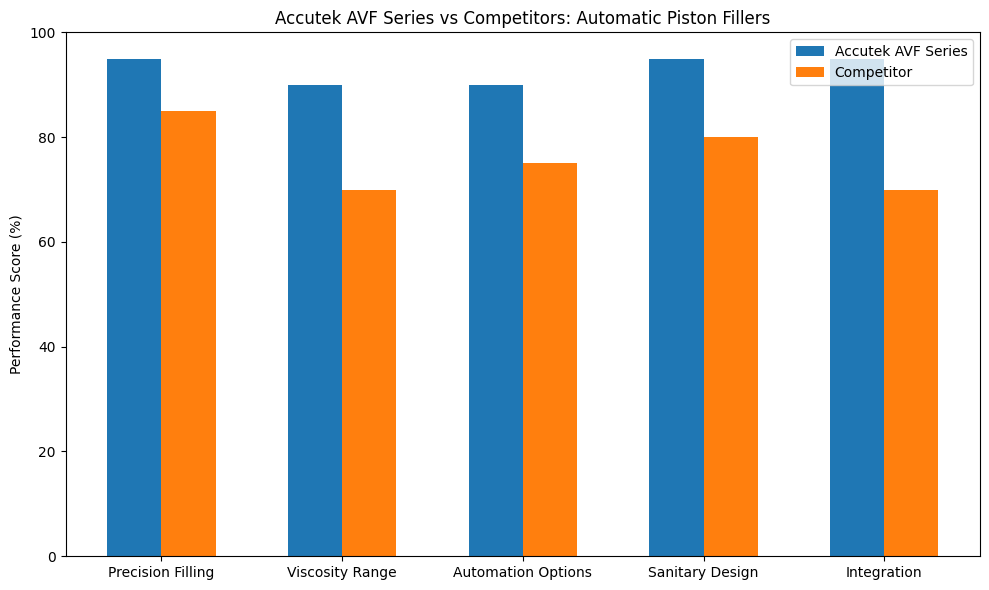

Before purchasing, manufacturers evaluate key features of piston filling machines. The chart below shows what buyers consider most important:

Chart Insight:

- Buyers prioritize precision, viscosity handling, automation, sanitary design, and line integration.

- Accutek AVF Series consistently ranks higher than typical competitors across all these factors.

Comparison: Accutek AVF Series vs Competitors

| Feature | Accutek AVF Series | Typical Competitor |

|---|---|---|

| Precision Filling | ±0.5% | ±1–2% |

| Viscosity Range | High (pastes, creams, gels) | Moderate (thin liquids only) |

| Automation Options | Multi-program digital control | Basic manual/semi-auto |

| Sanitary Design | Stainless steel, cGMP-ready | Limited or manual cleaning |

| Integration | Full line capability | Often standalone units |

This table demonstrates why Accutek Packaging Equipment Company, Inc. consistently outperforms competitors in precision, versatility, and turnkey integration.

For manufacturers handling pastes, creams, and highly viscous liquids, the Accutek AVF Series Automatic Piston Filler delivers:

- Consistent, high-precision filling to reduce waste and improve product quality

- Versatile handling of multiple viscosities and container formats

- Scalable automation for small batches and high-volume production

- Sanitary, compliance-ready design that meets cGMP and FDA standards

- Seamless integration into turnkey production lines with capping, labeling, and conveyors

Investing in the AVF Series ensures long-term reliability, efficiency, and regulatory compliance, making it one of the most trusted filling machine in the United States.