In any production environment, efficiency and consistency are the cornerstones of success. As demand grows and production lines scale up, manual packaging processes often struggle to keep pace. One of the first bottlenecks manufacturers encounter is at the capping stage—a critical step that ensures product safety, shelf life, and presentation quality.

For many businesses, investing in an automated capping machine is the key to unlocking faster throughput, fewer errors, and a more reliable packaging process. But when exactly is the right time to make the switch from manual or semi-automatic capping to full automation?

At Accutek Packaging Equipment, we help companies identify that perfect moment—and design the right packaging machine solution to match.

Why Automate the Capping Process?

Capping might appear straightforward, but it’s one of the most precise and repetitive tasks on a production line. Every cap must be applied with consistent torque, tightness, and alignment to protect the product and maintain brand quality.

Manual capping is feasible for small operations, but as production scales upward, inconsistencies may start to show up. Workers tire over time, torque levels vary, and production speed can’t match growing demand.

Automated capping machines solve these problems by applying consistent force, maintaining accuracy at high speeds, and ensuring uniform quality across every container.

Signs It’s Time to Upgrade to an Automated Capping Machine

If you’re wondering whether your business is ready to take the next step toward automation, here are some clear indicators that it might be time to upgrade your capping process:

- Rising Production Volume

If your team is struggling to keep up with growing orders, automation can provide the boost you need. Automated capping machines maintain a consistent pace that manual labor simply can’t match. - Inconsistent Product Quality

Uneven or improperly sealed caps can lead to leaks, product waste, or damaged packaging. Automated torque control ensures each cap is applied precisely, protecting your product’s integrity and brand reputation. - Increased Labor Costs or Turnover

Manual capping can be physically demanding, leading to fatigue and repetitive strain injuries. Automating the process reduces labor requirements and improves employee safety while freeing up staff for higher-value tasks. - Frequent Rework or Line Downtime

If your operators are constantly stopping the line to fix misapplied caps, automation can eliminate those interruptions and improve overall line efficiency. - Expanding Product Lines

If you’re introducing new products with different cap types or container sizes, a modern capping machine with quick-change components and programmable settings can make transitions seamless.

The Benefits of an Automated Capping System

Once your line is automated, the improvements are immediate and measurable.

- Speed and Efficiency: Automated systems can cap hundreds or thousands of containers per hour with unmatched accuracy.

- Consistency and Quality: Every cap is tightened to exact specifications, ensuring reliable sealing and professional appearance.

- Integration: When paired with filling machines and conveyors, cappers become part of a complete packaging machine system that keeps your entire line running smoothly.

- Cost Savings: Reduced waste, lower labor costs, and fewer product returns all contribute to a stronger bottom line.

Automation also gives you greater control and flexibility. Many of Accutek’s automated cappers feature programmable settings, touchscreen interfaces, and digital torque adjustment—making them easy to fine-tune for different caps, products, and speeds.

Accutek’s Expertise in Automated Capping

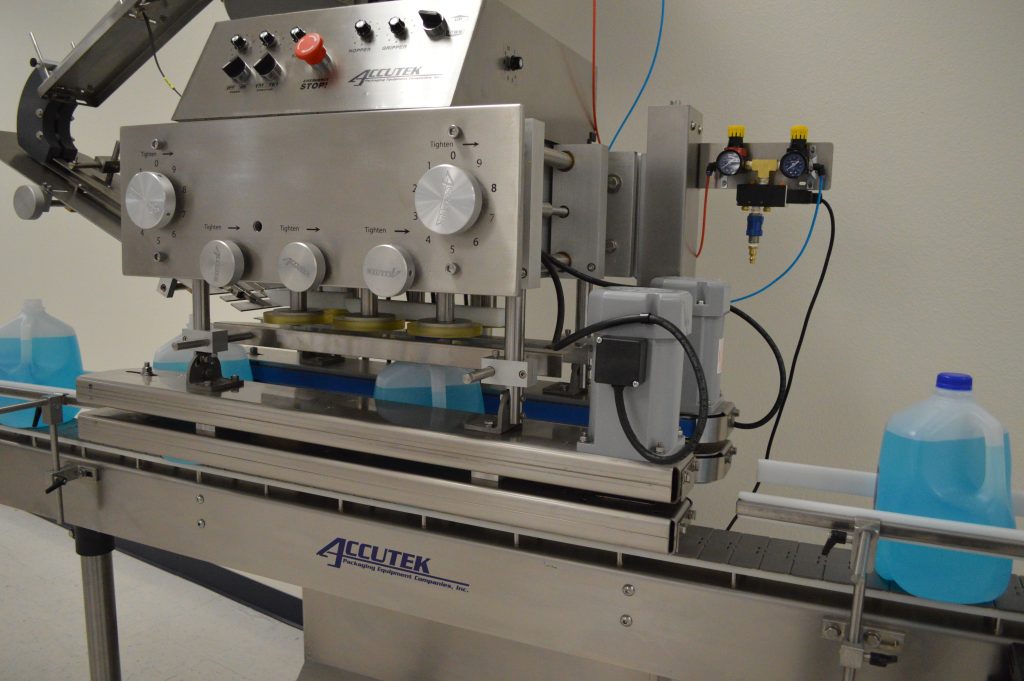

At Accutek Packaging Equipment, we design and build capping machines that meet the needs of businesses at every stage of growth. From entry-level automatic cappers to fully integrated high-speed systems, our equipment is built to last and engineered for precision.

Our spindle cappers, chuck cappers, and snap cappers can be seamlessly integrated with filling machines, conveyors, and labelers to form a complete packaging solution. Whether you’re upgrading from a manual setup or expanding an existing automated line, Accutek can help you configure a system that increases efficiency without compromising quality.

Take the Next Step Toward Efficiency

Upgrading to an automated capper promotes consistency, reliability, and growth. If you’re facing rising demand or quality control issues, automation could be the key to boosting your production.

Contact Accutek today to learn how our advanced capping and filling machines can transform your packaging line and prepare your business for the future of manufacturing.