Bottle orientation issues are one of the most underestimated causes of inefficiency in modern packaging lines. While filling, capping, and labeling systems often receive the most attention, improperly oriented containers can silently reduce throughput, cause labeling defects, and trigger frequent line stoppages.

For manufacturers across California, where high-output production, regulatory compliance, and labor efficiency are critical, bottle orientation is not a secondary concern—it is a foundational requirement for reliable automation. In this article, we examine why orientation failures occur, how they impact downstream operations, and why Accutek’s AccuSort 200 bottle orientator has become a proven solution for California-based production environments.

Why Bottle Orientation Is a Critical Engineering Problem in Packaging Lines

Bottle orientation refers to the process of aligning containers into a consistent position before they enter downstream operations such as filling, labeling, or capping. When this process is unstable, even the most advanced packaging machinery cannot perform to its designed capacity.

Common symptoms of orientation problems include:

- Containers entering labelers backward or sideways

- Missed or skewed labels due to inconsistent bottle alignment

- Accumulation pressure causing jams and micro-stoppages

- Increased operator intervention to manually correct bottle flow

In high-speed operations common throughout California’s food, beverage, cosmetic, and chemical industries, these issues compound rapidly, turning minor misalignment into measurable production losses.

The Hidden Cost of Poor Bottle Orientation in California Manufacturing

Many California manufacturers invest heavily in high-performance filling and labeling systems, only to experience ongoing inefficiencies caused by unstable container presentation. Orientation problems often lead to:

- Reduced Overall Equipment Effectiveness (OEE)

- Higher reject rates due to misapplied labels

- Premature wear on downstream equipment

- Increased labor costs for manual correction

Even a well-designed packaging machine cannot compensate for inconsistent bottle positioning upstream. Orientation failures force downstream systems to slow down, stop, or operate outside optimal tolerances.

Why Traditional Orientation Methods Fail at Scale

Basic orientation methods—such as guide rails, passive funnels, or manual alignment—may function at low speeds but rarely scale effectively. As line speeds increase, these methods struggle to maintain consistency, especially with non-round or asymmetrical containers.

This is where modern packaging machinery design principles matter. Automated orientators must:

- Handle a wide range of bottle shapes

- Maintain continuous flow without back pressure

- Integrate seamlessly with existing line equipment

Without these capabilities, orientation becomes the bottleneck rather than the enabler of automation.

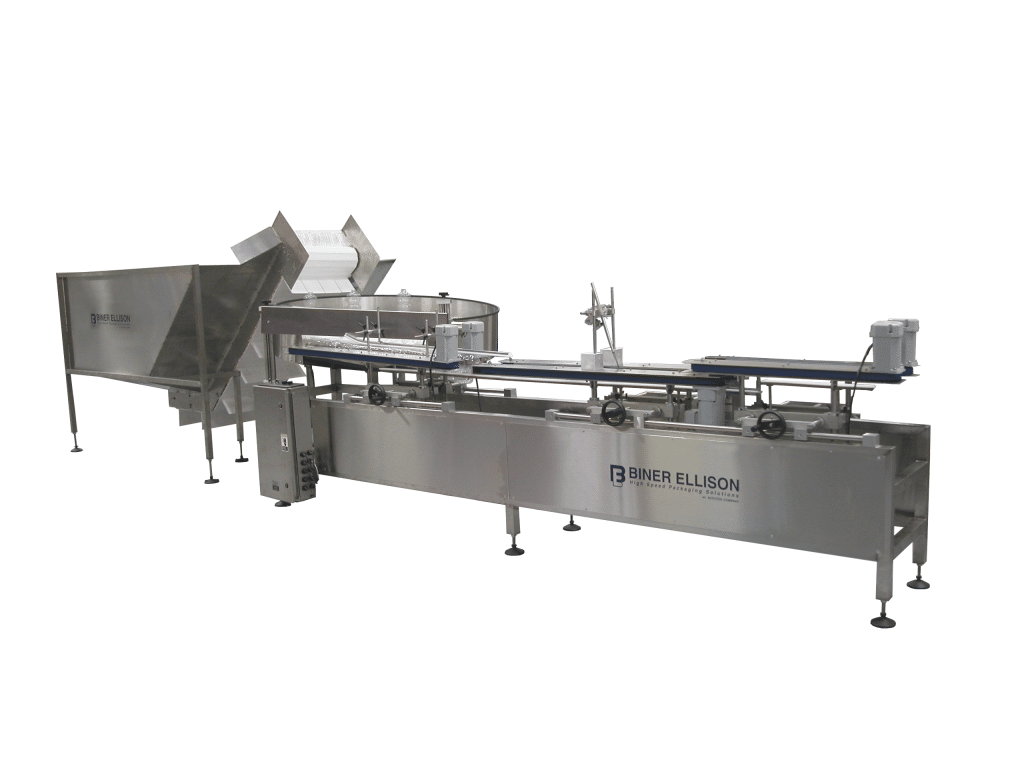

The AccuSort 200: Engineered Bottle Orientation for Real-World Lines

The AccuSort 200 Bottle Orientator is engineered specifically to address the orientation challenges faced by modern production lines. Designed for flexibility and reliability, it provides consistent bottle positioning before containers reach critical downstream equipment.

Key engineering advantages include:

- Controlled bottle singulation for stable downstream feed

- Adjustable orientation logic for different container geometries

- Smooth, continuous motion that minimizes jams and line disruptions

For California manufacturers operating under tight production schedules and compliance requirements, the AccuSort 200 delivers predictable performance without excessive operator oversight.

How Proper Orientation Improves Downstream Equipment Performance

Correct bottle orientation directly enhances the effectiveness of filling, labeling, and capping systems. When containers enter downstream stations uniformly aligned, equipment can operate at intended speeds and tolerances.

This results in:

- More accurate label placement

- Reduced mechanical stress on applicators

- Fewer emergency stops and fault conditions

In integrated lines, proper orientation allows every packaging machine to perform its function without compensating for upstream inconsistencies.

Why Accutek Is a Trusted Packaging Partner in California

Accutek’s reputation in California is built on system-level thinking, not isolated machines. Rather than treating orientation as an afterthought, Accutek engineers bottle handling as a critical component of total line performance.

By pairing orientators like the AccuSort 200 with filling, labeling, and capping solutions, Accutek delivers packaging machinery systems that function cohesively—reducing downtime, simplifying changeovers, and improving long-term reliability.

California Compliance, Reliability, and Long-Term Line Stability

California manufacturers often operate under stricter quality, safety, and environmental expectations. Equipment must not only perform efficiently but also support compliance and traceability requirements.

A stable orientation system reduces:

- Product handling errors

- Rework and waste

- Operator safety risks caused by manual intervention

When orientation is engineered correctly, it becomes a silent contributor to compliance, consistency, and operational confidence.

Key Takeaways for Bottle Orientation in California Packaging Lines

- Bottle orientation issues are a primary cause of hidden inefficiency in automated lines

- Poor orientation undermines the performance of downstream equipment

- The AccuSort 200 provides engineered, scalable orientation for diverse container types

- Consistent orientation allows every packaging machine in the line to operate at full capability

- Accutek’s system-based approach aligns with the demands of California manufacturing environments