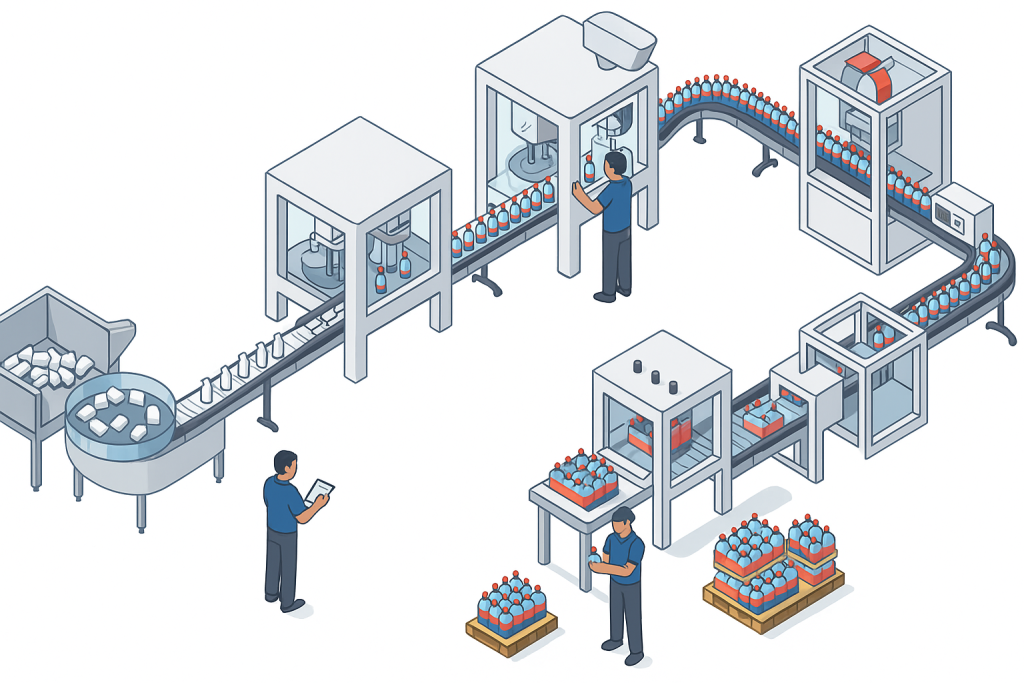

Modern manufacturing lines demand more than speed. They require repeatability, control, and long-term stability across filling, capping, and labeling. When any one of these systems drifts—even slightly—the entire packaging line suffers through downtime, rework, or compliance risk.

This is where engineering-driven packaging machinery separates itself from commodity equipment. Accutek’s approach focuses on mechanical precision, control system integration, and application-specific design, ensuring reliability across every stage of packaging—not just individual machines.

Engineering Reliability Starts With System-Level Thinking

Most packaging failures do not originate from a single machine. They occur at handoff points—where filling meets capping, or capping meets labeling.

Accutek engineers packaging systems as interconnected processes, not isolated assets. This system-level thinking ensures:

- Consistent container positioning from fill to label

- Stable torque and sealing integrity before labeling

- Controlled line speeds that protect label placement accuracy

Reliability is designed into the line—not corrected later.

Filling Reliability: Precision Before Speed

Accutek filling machines and systems are engineered around product behavior, not theoretical throughput.

Key Engineering Principles

- Matched filling technology to viscosity and flow characteristics

- Mechanical repeatability that minimizes drift over long production runs

- Tool-less or low-adjustment changeovers to reduce operator error

Reliability Outcomes

- Stable fill volumes across shifts

- Reduced foam, dripping, and overfill conditions

- Lower cleanup frequency and sanitation downtime

Filling Reliability Design Focus

| Engineering Element | Reliability Impact |

|---|---|

| Rigid frame construction | Maintains volumetric accuracy |

| Servo or pneumatic control tuning | Prevents fill inconsistency |

| Product-specific nozzle design | Reduces splash and foam |

| Sanitary flow paths | Supports FDA/GMP compliance |

Capping Reliability: Torque Control and Mechanical Alignment

Capping machines are often the hidden source of downstream labeling problems. A misaligned or inconsistently torqued cap creates instability that no labeler can correct.

Accutek’s capping systems are engineered to ensure repeatable closure integrity before labeling begins.

Engineering Priorities

- Controlled torque application across speed ranges

- Self-centering spindle or chuck designs

- Adjustable belt and container-handling geometry

Capping Reliability Outcomes

- Reduced cap back-off and seal failures

- Improved container stability entering labeling

- Lower reject rates during quality inspections

Capping Reliability Factors

| Failure Risk | Engineering Mitigation |

|---|---|

| Loose caps | Calibrated torque control |

| Cross-threading | Precision spindle alignment |

| Bottle spin | Stabilized side-belt systems |

| Seal inconsistency | Retorque validation options |

Labeling Reliability: Mechanical Control Over Cosmetic Perfection

Labeling machines reliability are measured in microns, milliseconds, and motion control. Accutek labelers are designed to maintain alignment accuracy even as speeds increase.

Labeling Engineering Approach

- Rigid label applicator mounts to prevent vibration drift

- Precision container handling for round, square, and irregular containers

- Synchronized motion between conveyors and applicators

Labeling Reliability Results

- Consistent label placement across long runs

- Reduced wrinkling, skewing, and edge lift

- Faster startup with fewer initial rejects

Labeling Reliability Metrics

| Design Feature | Production Benefit |

|---|---|

| Servo-driven applicators | Placement repeatability |

| Adjustable guide systems | Container stability |

| Modular label heads | Faster maintenance |

| Vision-ready integration | Quality validation support |

Reliability Across the Line: Why Integration Matters

True reliability emerges when filling, capping, and labeling are engineered as one system.

Integrated Line Advantages

- Balanced line speeds prevent bottlenecks

- Fewer micro-stoppages caused by misalignment

- Easier troubleshooting through unified control logic

Integrated Reliability Comparison

| Approach | Downtime Risk | Scalability | Long-Term Stability |

|---|---|---|---|

| Standalone machines | High | Limited | Variable |

| Integrated Accutek line | Low | High | Predictable |

Built for Long-Term Manufacturing Demands

Accutek reliability engineering extends beyond initial installation:

- Heavy-duty components selected for industrial duty cycles

- Documentation and support aligned with regulated industries

- Upgrade paths that protect capital investment over time

This ensures manufacturers are not forced into premature replacements as production grows.

Key Takeaways: Engineering Reliability Across Packaging Operations

- Reliability is engineered at the system level, not patched per machine

- Filling accuracy protects downstream capping and labeling stability

- Torque-controlled capping prevents cosmetic and seal-related failures

- Labeling precision depends on mechanical control, not speed alone

- Integrated packaging lines outperform standalone equipment in uptime and consistency

By engineering reliability across filling, capping, and labeling as a unified process, Accutek Packaging Equipment Company, Inc. delivers packaging machinery designed for real-world manufacturing demands—not theoretical performance.