Choosing between pressure-sensitive and shrink sleeve labeling is not a branding decision—it is an engineering decision. While both technologies are widely used across food, beverage, cosmetic, and household products, each introduces distinct mechanical, operational, and cost trade-offs that directly impact line efficiency, reliability, and scalability.

Manufacturers that evaluate labeling systems based solely on aesthetics or marketing preferences often encounter avoidable downtime, higher operating costs, and integration challenges later in production. This article breaks down the engineering realities behind each method and explains how to select the right solution based on container behavior, production goals, and long-term operational strategy.

Understanding Pressure-Sensitive Labeling at the Mechanical Level

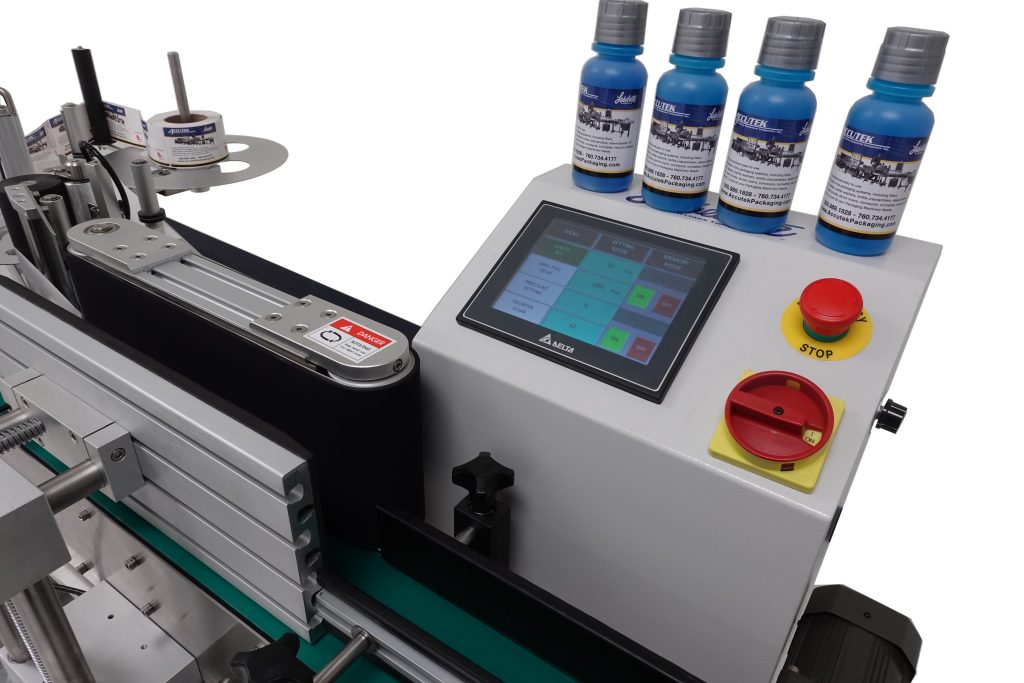

Pressure-sensitive labeling machine applies pre-printed labels using adhesive backing and controlled wipe-down or wrap mechanisms. From an engineering standpoint, this method emphasizes precision, repeatability, and speed stability.

Core engineering characteristics

- Label placement controlled mechanically and electronically

- Adhesive activation requires no heat

- Label accuracy depends on container stability and timing

Pressure-sensitive systems are widely used because they integrate easily into existing lines and support rapid changeovers.

Engineering strengths

| Attribute | Engineering Advantage |

|---|---|

| Label placement | High positional accuracy |

| Line speed stability | Predictable at high throughput |

| Changeovers | Faster with tool-less designs |

| Energy consumption | Low (no heat tunnel) |

This method favors manufacturers prioritizing operational efficiency, uptime, and SKU flexibility.

Understanding Shrink Sleeve Labeling from a System Perspective

Shrink sleeve applies a film sleeve that is shrunk onto the container using heat or steam. While visually impactful, it introduces additional system complexity.

Core engineering characteristics

- Sleeve placement followed by heat or steam activation

- Requires tunnel integration and thermal control

- Film behavior varies by material and thickness

Shrink sleeve systems must manage thermal dynamics, making them more sensitive to line speed changes and container variability.

Engineering strengths

| Attribute | Engineering Advantage |

|---|---|

| Container coverage | 360-degree branding |

| Shape adaptability | Works well with complex geometries |

| Tamper evidence | Integrated sleeve options |

| Shelf impact | High visual differentiation |

Shrink sleeve labeling excels where container design and branding drive purchasing decisions—but it demands tighter engineering control.

Line Integration and Stability Trade-Offs

One of the most significant differences between the two technologies is how they behave within an integrated packaging line.

Integration comparison

| Factor | Pressure-Sensitive | Shrink Sleeve |

|---|---|---|

| Mechanical complexity | Moderate | High |

| Thermal dependency | None | Required |

| Speed sensitivity | Lower | Higher |

| Conveyor tuning | Simpler | More critical |

Pressure-sensitive labeling generally produces more stable line behavior, especially at higher speeds or during frequent changeovers.

Shrink sleeve labeling requires careful synchronization between applicator and tunnel to avoid distortion, skewing, or inconsistent shrink patterns.

Changeovers, SKUs, and Operational Flexibility

Manufacturers with growing product portfolios often underestimate how labeling choice affects daily operations.

Changeover impact

| Operational Scenario | Pressure-Sensitive | Shrink Sleeve |

|---|---|---|

| Frequent SKU changes | Efficient | Slower |

| Multiple container sizes | Easier | More setup |

| Short production runs | Cost-effective | Less efficient |

| Operator dependency | Lower | Higher |

From an engineering standpoint, pressure-sensitive systems better support SKU expansion and production agility.

Energy Use, Maintenance, and Long-Term Cost

Shrink sleeve labeling introduces energy-intensive components that affect operating cost and maintenance schedules.

Cost and maintenance comparison

| Cost Area | Pressure-Sensitive | Shrink Sleeve |

|---|---|---|

| Energy consumption | Low | High |

| Maintenance frequency | Lower | Higher |

| Wear components | Minimal | Tunnel & heating elements |

| Downtime risk | Lower | Higher |

These differences become more pronounced as line speeds increase or production schedules tighten.

Matching Labeling Technology to Container Behavior

Engineering-driven selection considers how containers behave under motion, pressure, and heat.

Container suitability matrix

| Container Type | Recommended Technology |

|---|---|

| Cylindrical bottles | Pressure-sensitive |

| Square or flat-sided | Pressure-sensitive |

| Irregular or contoured | Shrink sleeve |

| Lightweight plastics | Pressure-sensitive (preferred) |

| Full-body branding | Shrink sleeve |

This matrix helps prevent downstream issues such as container deformation, label skew, or tunnel-induced instability.

Engineering-Led Labeling System Design

Manufacturers increasingly rely on suppliers that understand these trade-offs at a system level. Companies such as Accutek Packaging Equipment Company, Inc. support both labeling technologies, allowing engineers to evaluate performance, cost, and scalability before committing to a specific approach.

This flexibility enables manufacturers to choose labeling solutions based on engineering fit, not marketing trends.

Key Takeaway: Choosing the Right Labeling Technology

- Pressure-sensitive labeling prioritizes stability, efficiency, and flexibility

- Shrink sleeve labeling delivers branding impact but adds system complexity

- Integration and thermal control drive long-term reliability

- Changeovers and energy costs differ significantly

- Container behavior should guide technology selection

The right choice balances engineering performance, operational reality, and long-term growth goals—not just label appearance.