Are you a manufacturer looking for ways to boost output, cut down on waste, and maintain consistent product quality?

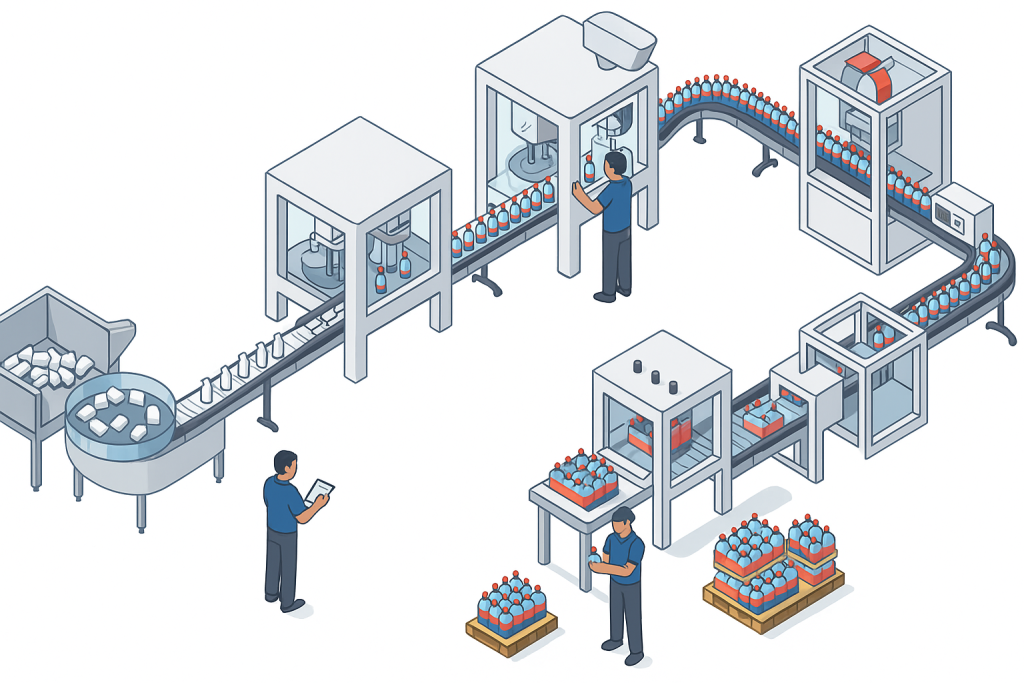

One of the most effective ways to achieve these goals is through integrated packaging machines—systems that combine multiple packaging processes, such as filling and capping, into a single streamlined operation.

At Accutek Packaging Machine & Equipment, we specialize in helping companies like yours optimize their production lines with complete packaging solutions. From precision filling machines to reliable capping machines, our integrated systems are designed to work together seamlessly—boosting productivity while maintaining the highest quality standards.

The Role of Filling Machines in Modern Production

Efficient packaging machine lines usually include a filler. Whether you’re handling liquids, creams, pastes, or powders, the filling machine helps dispense your product into containers with accuracy and consistency.

Modern liquid filling machines use sensors and precision nozzles to ensure exact fill levels, cutting down on waste and boosting production. This is essential because In industries like food and beverage, pharmaceuticals, and cosmetics, even slight inconsistencies can lead to costly product recalls or dissatisfied customers.

Completing the Process with Capping Machines

Once the product is filled, it must be sealed securely—and that’s where cappers come in. Capping is a crucial step that protects product integrity, prevents leaks, and enhances shelf appeal.

A dependable capping machine ensures each cap is applied with the correct torque and alignment, maintaining a professional finish while preserving freshness and safety.

At Accutek, we offer several types of capping equipment, including spindle cappers, chuck cappers, and snap cappers, each suited for specific cap and container types.

When integrated with a filler, conveyor, and labeler, a capping machine completes the automation cycle. This integration enables transitions between each stage, minimizing downtime and manual handling.

Why Integrated Packaging Machines Are the Future

Integrating filling and capping machines into one cohesive system offers several benefits that standalone machines simply can’t match.

- Improved Efficiency – When machines can work together, product transfer is faster and smoother, reducing bottlenecks and increasing production.

- Consistent Quality – Automation reduces human error, so every container is filled and sealed to exacting standards.

- Reduced Labor Costs – You don’t need as many operators to manage multiple systems, allowing your staff to focus on other tasks.

- Smaller Footprint – Integrated systems usually occupy less space on the floor.

- Easier Maintenance – Working with a single manufacturer like Accutek simplifies maintenance, training, and parts replacement.

Streamlining the production process makes it easier to reduce downtime, boost reliability, and meet growing consumer demand.

If you’re ready to streamline your production line with a capping or filling machine, contact Accutek today. We can help you find the perfect setup to maximize your output and maintain exceptional quality from start to finish. Our goal is to make your packaging line as efficient, accurate, and reliable as possible—so you can focus on growing your business.