Hot melt glue remains one of the most reliable and cost-effective methods for applying wrap labels at high production speeds. When properly engineered, hot melt adhesive systems deliver consistent label adhesion, clean application, and dependable uptime—even in demanding, high-output environments.

For manufacturers running beverage, food, household chemical, or personal care lines, success with hot melt glue labeling depends on more than adhesive choice alone. Line speed, container geometry, glue temperature control, and the labeling machine itself all play a critical role.

This article explains how hot melt glue performs in high-speed wrap labeling applications and how Accutek’s hot melt labeling systems—RL-HG 540, Labelette HG, Labelette SG, and Labelette FS—are designed to support consistent, production-ready results.

Why Hot Melt Glue Is Still Widely Used in Wrap Labeling

Hot melt adhesive is applied in a molten state and bonds quickly as it cools against the container surface. This fast set time makes it well suited for wrap labeling, where precise timing between container rotation, label feed, and adhesive transfer is required.

When optimized correctly, hot melt glue labeling offers:

- Strong adhesion on paper and many plastic labels

- Clean, repeatable application at high speeds

- Lower material costs compared to pressure-sensitive labels

- Simple mechanical integration with wrap labeling machines

However, as line speeds increase, adhesive behavior becomes less forgiving. Inconsistent temperature, poor glue pattern control, or mechanical instability can quickly lead to label lift, stringing, or downtime.

Key Hot Melt Glue Considerations in High-Speed Labeling

In high-speed wrap labeling environments, hot melt glue must perform consistently under continuous heat and motion. The most important factors to control include:

| Performance Factor | Why It Matters |

|---|---|

| Adhesive temperature | Affects viscosity, transfer consistency, and stringing |

| Open time | Determines how long the adhesive remains tacky |

| Glue pattern control | Ensures even adhesion without excess waste |

| Container stability | Maintains accurate label placement at speed |

| Machine synchronization | Aligns glue application with label and bottle movement |

When these variables are aligned, hot melt glue becomes a stable part of the process rather than a frequent

Accutek Hot Melt Glue Labeling Systems

Accutek offers multiple hot melt wrap labeling machines designed for different production volumes and container types—ranging from semi-automatic systems to high-speed rotary platforms.

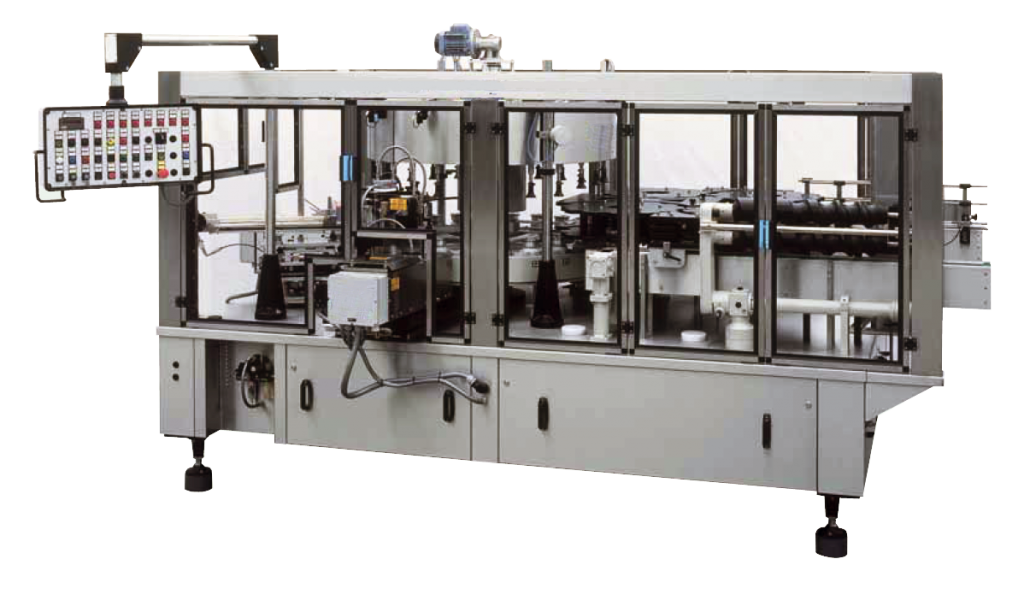

RL-HG 540 — High-Speed Rotary Hot Melt Wrap Labeler

The RL-HG 540 is engineered for continuous, high-output wrap labeling using hot melt adhesive. Its rotary design supports consistent container handling and precise glue application at elevated speeds.

Key advantages include:

- High-speed labeling for cylindrical containers

- Optimized hot melt glue transfer for full-wrap labels

- Continuous operation with minimal downtime

- Designed for integration into automated production lines

The RL-HG 540 is best suited for manufacturers where throughput, uptime, and repeatability are critical.

Labelette HG — Semi-Automatic Hot Melt Wrap Labeler

The Labelette HG provides a flexible solution for operations that require reliable hot melt labeling without full automation. It is commonly used for short runs, specialty products, or facilities with moderate production volumes.

Notable features:

- Digital thermostat for consistent adhesive temperature

- Adjustable glue length and wrap coverage

- Quick setup and simple operation

- Suitable for spot, partial, or full-wrap labels

This system is ideal for companies seeking accuracy and control with a smaller footprint.

Labelette SG — Skip-Glue Hot Melt Labeler

The Labelette SG is designed to reduce adhesive consumption by applying hot melt glue only where it is needed. Instead of continuous glue coverage, skip-glue patterns are used to secure labels efficiently.

Benefits include:

- Lower adhesive usage and operating cost

- Adjustable skip-glue patterns

- Clean application for thinner labels

- Same ease of use as the Labelette HG

The Labelette SG is a strong option for cost-conscious operations without sacrificing label security.

Labelette FS — Hot Melt Labeling for Flat or Specialty Containers

The Labelette FS is built for containers that fall outside traditional cylindrical formats, including rectangular cans, canisters, and flat-panel packaging.

Key capabilities:

- Custom skip-glue patterns for flat surfaces

- Stable container handling for non-round shapes

- Touchscreen PLC control for repeatable setups

- Suitable for metal, plastic, and composite containers

This machine expands hot melt wrap labeling into specialty packaging applications.

Matching the Right Machine to Your Production Needs

| Machine | Production Speed | Glue Pattern | Best Application |

|---|---|---|---|

| RL-HG 540 | High | Continuous hot melt | High-speed cylindrical wrap labeling |

| Labelette HG | Medium | Continuous hot melt | Semi-automatic wrap labeling |

| Labelette SG | Medium | Skip glue | Reduced adhesive usage |

| Labelette FS | Low–Medium | Skip glue | Flat or specialty containers |

Common Hot Melt Labeling Issues and Process-Level Solutions

| Issue | Likely Cause | Recommended Action |

|---|---|---|

| Glue stringing | Adhesive temperature too high | Lower temperature and stabilize heating |

| Label lift | Insufficient glue coverage | Adjust glue pattern or switch to continuous glue |

| Inconsistent adhesion | Container movement variation | Improve container handling and timing |

| Excessive cleaning | Adhesive degradation | Optimize temperature and purge cycles |

Addressing these issues at the process level helps maintain consistent labeling performance over long production runs.

Best Practices for Long-Term Performance

To keep hot melt wrap labeling systems operating efficiently:

- Maintain stable adhesive temperatures

- Clean glue components on a scheduled basis

- Monitor adhesive usage for early issue detection

- Train operators on glue behavior and adjustment indicators

Well-maintained systems reduce downtime and extend component life.

Key Takeaways for High-Speed Wrap Labeling with Hot Melt Glue

- Hot melt glue performance directly affects label accuracy, line speed, and overall equipment efficiency in wrap labeling operations

- Consistent adhesive temperature and controlled glue patterns are essential for preventing stringing, label lift, and downtime

- High-speed applications benefit from rotary systems like the RL-HG 540, which stabilize container handling and glue transfer at scale

- Semi-automatic solutions such as the Labelette HG and Labelette SG offer flexibility for shorter runs while maintaining precise adhesive control

- Skip-glue configurations help reduce adhesive consumption without compromising label security

- Specialty containers require purpose-built solutions like the Labelette FS to maintain proper label registration on flat or non-round surfaces

- Treating hot melt glue as a process variable rather than a consumable leads to cleaner operation, stronger adhesion, and more predictable results

- Proper machine selection, setup, and maintenance allow manufacturers to scale production without sacrificing label quality