So you’re in the market for a labeling machine that will meet some specific production needs, but you’re not sure what you want or even need. It’s definitely not a simple choice to make, so it’s important to do your due diligence so you select the right equipment.

With that in mind, here are four questions to ask yourself when you’re in the market for a labeler.

What Problem Does Your Labeling Machine Need to Solve?

Of course, the answer to this question can probably be boiled down to something broad, like, “It’s taking too long to label my products by hand.” In that case, most labelers are going to be able to solve your problem.

But maybe you have a more specific issue, like a gap in your current production line. Or you don’t have enough space for a production line, so you need something smaller and more compact. In that case, the size of your machine would play a very decisive role in your decision.

What’s Your Budget for a Labeling Machine?

We come to the ever-looming question: “Can I afford it?” While only you can answer that, it’s still important to take stock of your own needs and budget accordingly.

A higher-end, automatic labeler might cost you around $30,000, while a semi-automatic, tabletop machine might cost around half of that. Also, depending on your production needs, you may also have to invest in upgrades or other options that can help you attain your production goals.

Which brings us to the next question:

Does Your Labeling Machine Need Customizations?

You have your eye on a specific labeler, but it doesn’t do everything you want it to. Which means that you may need to shell out for some additional gadgets that will help you get where you need to.

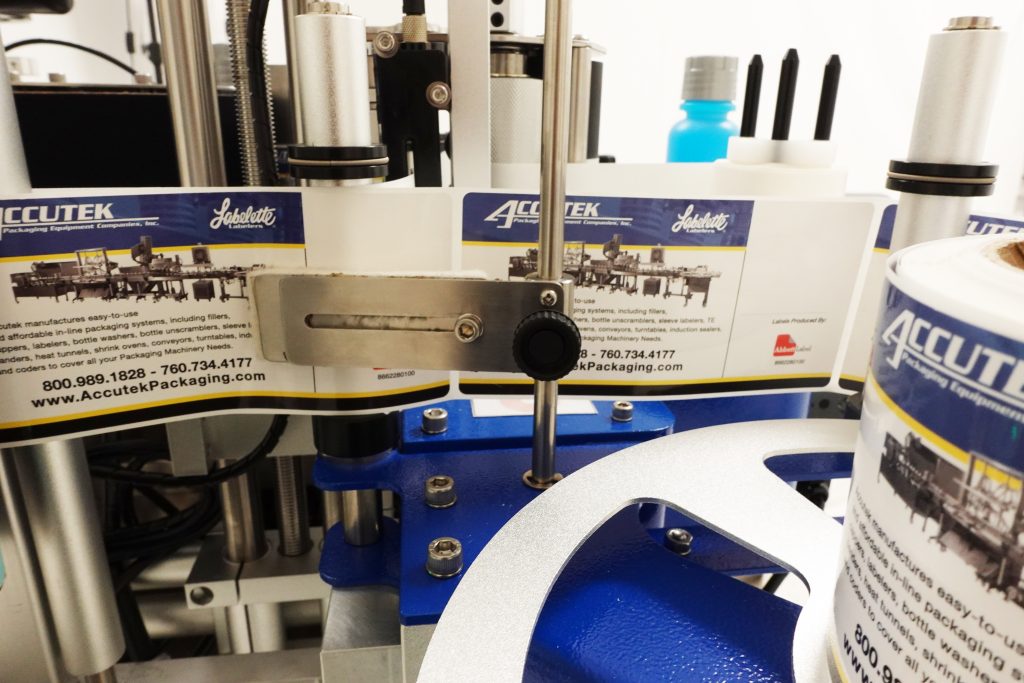

Do you need a static eliminator for your plastic labels? A thermal transfer printer to add expiration dates? A sensor designed to detect whether your specific kind of label is present?

If so, consult with the vendor and see what additional components would be best for helping you apply factual, high-quality labels to your products.

Do You Need an Automatic or Semi-Automatic Labeling Machine?

We have a whole blog post that breaks down the difference between auto and semi-auto labelers, so if you want more in-depth information on that, we encourage you to check it out.

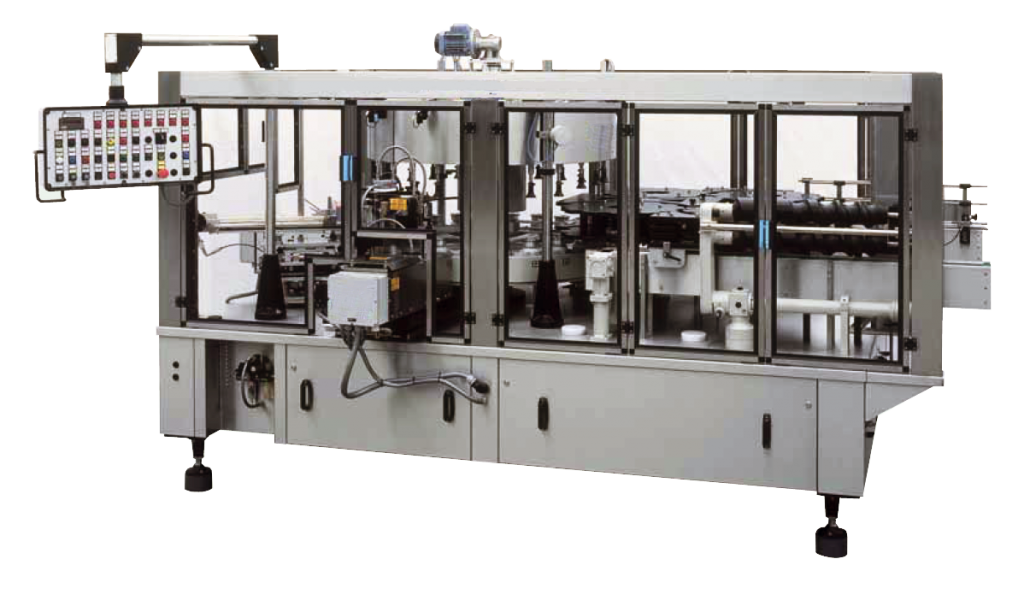

But to sum it up, automatic labelers are usually larger, while semi-automatic labelers tend to be smaller, and they require more direct input from an employee.

It all comes down to your production needs: Do you need a machine that can be incorporated into a production line and doesn’t need as much human interaction? Go with an automatic labeler. Do you just need something that you can easily port around, and otherwise don’t need to pair with other machines, like turntables and standalone conveyors? Then a semi-automatic labeling machine is what you need.

For all other questions, contact Accutek Packaginge. We’ll be happy to help you figure out the optimal configuration for the best labeler to take on your production needs.