When you’re in the market for an industrial labeling machine, consider the type of label you plan on using. Whether pressure-sensitive, shrink sleeve, or top-down, each imposes unique mechanical demands. So knowing these differences guides your machinery choice.

Let’s look a little deeper into these label types.

Pressure-sensitive (Self-adhesive) Labels

These are the most common labels: adhesive is pre-applied, you just peel and stick. A packaging and labeling machine designed for pressure-sensitive labels typically includes components like:

- A label unwind

- Peel-plate

- Tamp applicator

- Sensors

- Or rollers

Such machines tend to be simple and relatively cost-effective, like Accutek’s SPS-104. They can apply labels quickly, work on many bottle shapes, and are simple to set up. However, the adhesive quality must match the substrate, and the labels can be sensitive to surface contamination. So keep that in mind.

Sleeve (Shrink) Labels

Sleeve labels are heat-shrink films that wrap tightly around the container after passing through a heat tunnel. A labeling machine for bottles that handles sleeves can include a film dispenser, heat tunnel, and guiding systems. Accutek offers sleeve labelers that can run up to 150 containers per minute.

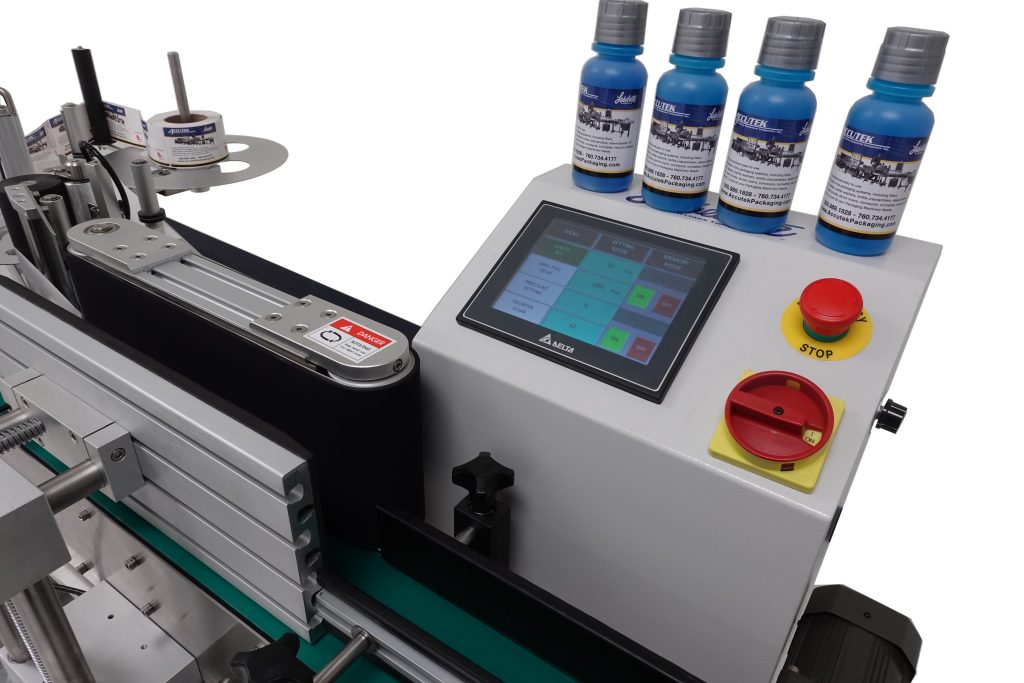

Take the SL1-150, for example. This sleever can work with a heat tunnel to shrink sleeve labels onto bottles for clear, clean adhesion. It also features a simple touchscreen control system and memory functions, in addition to being simple to set up.

Top-down Labeling

Top-down labels apply a label on the top surface (e.g., lids, caps). Top-down labelers can use vacuum or tamp applicators that press down on the top face. Accutek’s own top-down units (like the APS-104) are easy to use and economical.

This type of label is commonly used for jars, tubs, pails, or when you want a seal or branding on lids.

Choosing Based on Business Needs

If your labels are simple adhesive type, a pressure-sensitive labeling machine is your safe bet. If you want full-coverage or “360°” branding, consider a sleeve labeler. If you package jars or want a lid seal, a top-down applicator is appropriate.

You can also combine machine types, like a wrap-around for labeling containers and a top-down for labeling lids. Why? To incorporate them into a single production line. You can do likewise other machines, like fillers and cappers, for a complete production line.

Say a skincare brand sells jars with lid branding and side labels. That brand might use a wrap-around pressure-sensitive labeler for the jar body and a top-down applicator for the lid. A manufacturer like Accutek can integrate these into a hybrid line, making it easier for them to label their products.

Conclusion

It’s best if your choice of industrial labeling machine aligns with the label type you intend. Pressure-sensitive machines are versatile and cost-effective. Sleeve labeling offers strong branding and tamper evidence but adds complexity. Top-down machines specialize in lids or surfaces.

Matching economics, container design, and throughput needs will help you make the right investment in a packaging and labeling machine.

Need some assistance with figuring out what kind of labeling machine for bottles would be best compatible with your labels? Give Accutek a call. We can help find you the perfect machine for your manufacturing needs.