As a manufacturer of packaging machines, we feel qualified to say that labeling machines are pretty nifty. After all, they make it so much easier to apply labels onto your products, reducing human error and boosting efficiency.

You may be asking yourself: What kind of labeler do I need? Of course, the answer is going to depend on your own production needs, whether that’s factoring in your product’s specifications, your physical production space, and more.

But we can help narrow your search down by dividing labelers into two different camps: Automatic and semi-automatic. Let’s go over each to break down what makes them unique and how they can potentially suit your production needs.

Automatic Labeling Machines

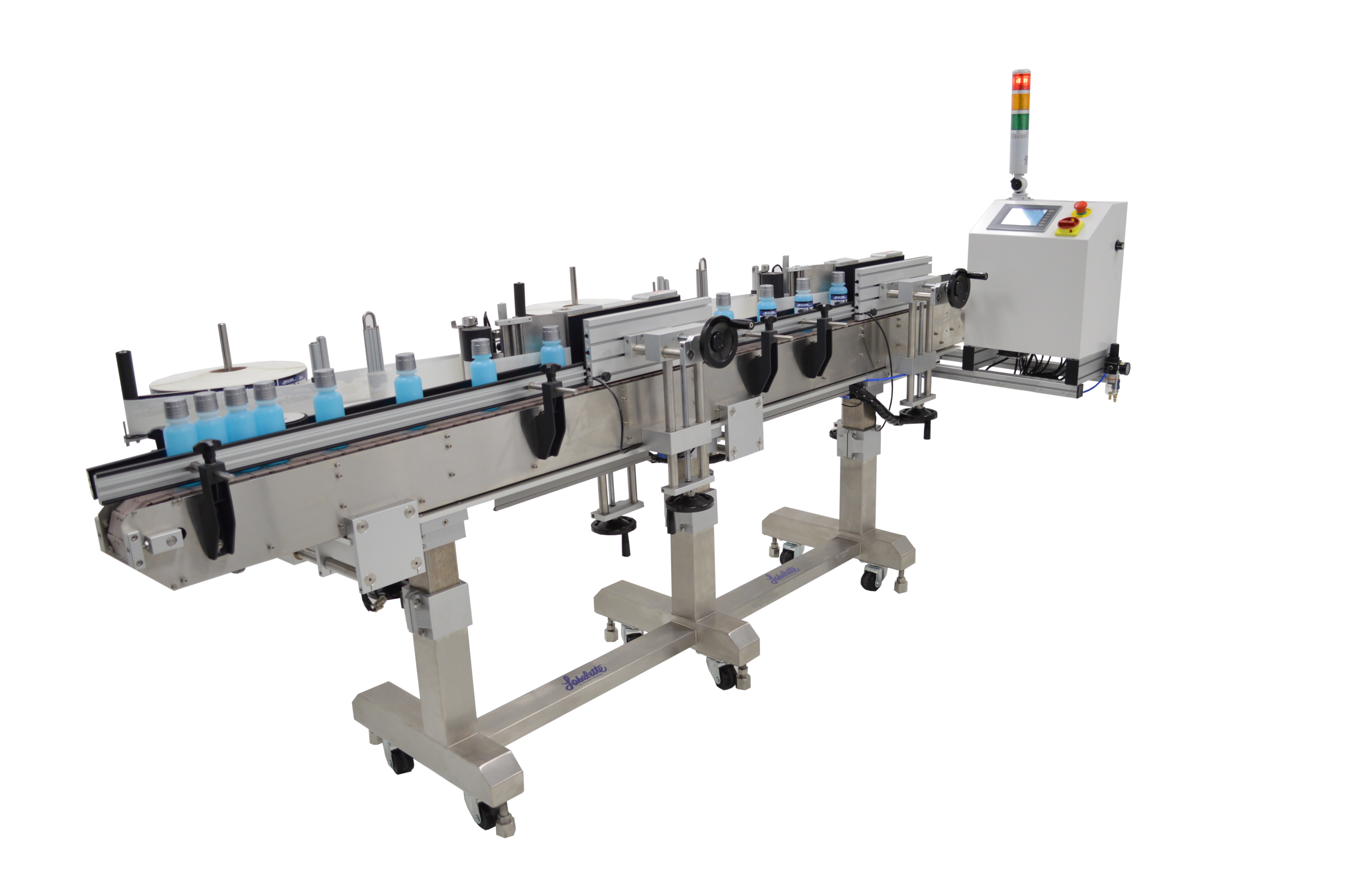

It’s easy to recognize an automatic labeler at a glance; they’re usually large. Large enough that they require wheels to be moved around, unlike semi-automatic labelers, which can usually be lifted or moved around on a cart.

What really sets automatic labelers apart from their semi-automatic cousins is that they’re capable of orienting the containers they’re about to label. They can do this with rollers or belts that might be made with, for instance, foam. They may also have plastic rails that can help guide the container towards the wrapping station.

These labelers also tend to handle larger labels. For instance, Accutek’s PSA line can apply 6.75” labels. Not only that, but its longer conveyor belt lets it process a greater number of containers.

It helps that automatic labelers can be integrated into existing production lines or easily paired with new machinery, like conveyor belts or turntables. But if needed, they can still work as semi-automatic or standalone machines; they just need one person to stand at each end. For production efficiency you can read more about it here: The Role of Automated Labeling Systems in Optimizing Production Efficiency

Automatic labeling machines do tend to lean towards the more expensive side than semi-auto labelers, on account of their size and additional capabilities.

Semi-Automatic Labeling Machines

What mainly makes semi-automatic labeling machines distinct from their completely automatic counterparts is their relatively smaller size and compact nature.

Take Accutek’s SPS line, for example. These machines are much, much smaller than the APS and PSA lines. As such, they can be easily lifted and placed on tabletops or other convenient surfaces. The APS and PSAs, on the other hand, are significantly larger and need to be pushed around on wheels.

Unlike an automatic labeler, a semi-automatic machine is typically a standalone component in the production process. Because of this, a human operator must be present to manually place the products on the belt or conveyor. This is a much slower process than using an automatic line.

Also, because of their relatively compact size, semi-automatic labelers usually handle smaller labels. The SPS can apply, at maximum, labels that are approximately 4.5” tall and less than 10” in diameter. Also, its 3.25” fabric conveyor can only allow so many conveyors.

So you’ll want a semi-automatic labeler if you’re looking for something on the smaller size that doesn’t cost quite as much, and your production needs aren’t as intensive.

If you want to learn more about automatic and semi-automatic labelers, give Accutek a call. We’ll be happy to talk in greater detail with you about how these labelers can meet your production needs.