Many U.S. packaging lines look stable.

Packaging machines run near rated speed. Major alarms are limited. Shift totals seem acceptable.

Yet output still drifts.

A line set at 120 bottles per minute may fluctuate between 100 and 118 without a clear failure. Supervisors increase speed to recover volume. The instability continues.

The problem is rarely maximum speed.

It is micro-stops.

The Illusion of Stability

Most dashboards track:

- Major downtime

- Average line speed

- Shift production totals

- Long alarm events

Micro-stops rarely stand out.

A micro-stop is a short pause, often under five seconds. The machine stops and restarts automatically. It may not trigger a major fault.

Each pause looks harmless.

Over a shift, hundreds of them reduce sustained throughput.

Where the Assumption Breaks

The common belief is simple:

“If the machine restarts quickly, nothing important was lost.”

This assumption fails because a packaging line is a timing system.

Each restart changes:

- Container spacing

- Fill timing

- Cap torque rhythm

- Label alignment

- Conveyor pressure

The line keeps moving.

But it is no longer synchronized.

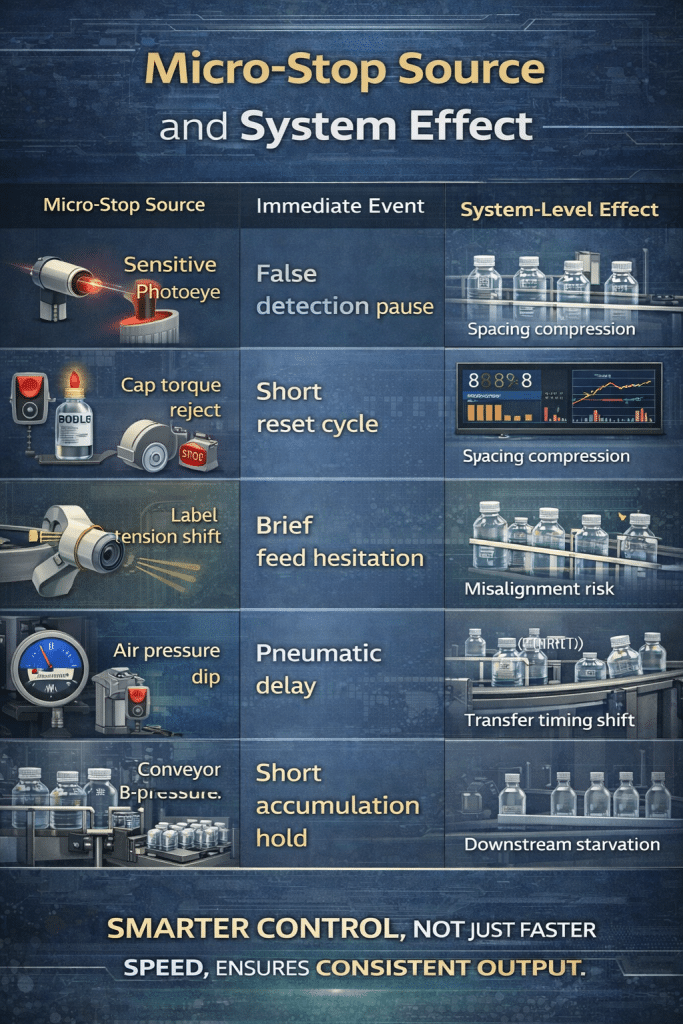

Micro-Stop Source and System Effect

| Micro-Stop Source | Immediate Event | System-Level Effect |

|---|---|---|

| Sensitive photoeye | False detection pause | Spacing compression |

| Cap torque reject | Short reset cycle | Rhythm disruption |

| Label tension shift | Brief feed hesitation | Misalignment risk |

| Air pressure dip | Pneumatic delay | Transfer timing shift |

| Conveyor back-pressure | Short accumulation hold | Downstream starvation |

These are not major failures.

They are repeated timing disturbances.

Why Micro-Stops Lower OEE

Micro-stops rarely appear as downtime. They reduce performance instead.

Repeated short pauses:

- Lower sustained output

- Increase micro-adjustments

- Reduce line balance

- Add hidden performance loss

In U.S. plants where labor and compliance costs are high, small instability becomes expensive.

Engineering Repair: Stabilize Before You Accelerate

Throughput stability improves when the system is tuned for rhythm, not peak speed.

Control Logic Refinement

Control systems often react too quickly.

Adjusting timing settings can reduce unnecessary pauses.

Control Adjustment and Stability Outcome

| Adjustment Area | What Changes | Stability Outcome |

|---|---|---|

| Sensor delay | Reduces false triggers | Fewer short stops |

| Restart timing | Smooth restart ramp | Less compression |

| Accumulation threshold | Better buffer control | Reduced starvation |

| Reject confirmation timing | Prevents rapid cycling | Improved rhythm |

The goal is controlled response.

Not instant reaction.

Mechanical Consistency Over Higher RPM

Increasing speed reduces tolerance.

Instead, focus on:

- Smooth transfers

- Stable conveyor speed

- Even starwheel engagement

- Uniform torque application

Accutek Packaging Equipment designs filling, capping, and labeling systems for mechanical consistency across sustained runs. For example, Accutek rotary capping systems maintain steady torque under load. Consistent torque reduces reject-triggered pauses.

Stable mechanics reduce interruptions.

Reduced interruptions improve sustained output.

Speed Increase vs Stability Impact

| Action Taken | Short-Term Effect | Long-Term Impact |

|---|---|---|

| Increase RPM | Temporary volume gain | Greater instability |

| Reduce sensor tolerance | Fewer pauses initially | More false stops later |

| Improve mechanical rhythm | Stable spacing | Sustained throughput |

| Optimize control timing | Smoother restart | Higher predictability |

Speed hides instability.

Rhythm solves it.

Why Speed Magnifies the Problem

Higher speeds shrink timing margins.

At elevated rates:

- Sensors have less tolerance

- Alignment windows narrow

- Torque variation matters more

- Back-pressure builds faster

Instability grows faster than output.

True improvement comes from eliminating interruptions.

Explaining It Simply

Imagine highway traffic.

If drivers tap their brakes every minute, traffic never flows smoothly. Even if cars speed up again, waves of compression reduce efficiency.

Packaging lines behave the same way.

Micro-stops are brief brake taps.

Remove them, and flow becomes predictable without raising speed.

Why This Matters in the United States

U.S. manufacturers face:

- High labor costs

- Strict regulatory standards

- Frequent SKU changes

- Tight delivery schedules

Stable throughput improves:

- Labor planning

- Inventory control

- Changeover accuracy

- Quality consistency

Predictable output is more valuable than short bursts of high speed.

Final Perspective

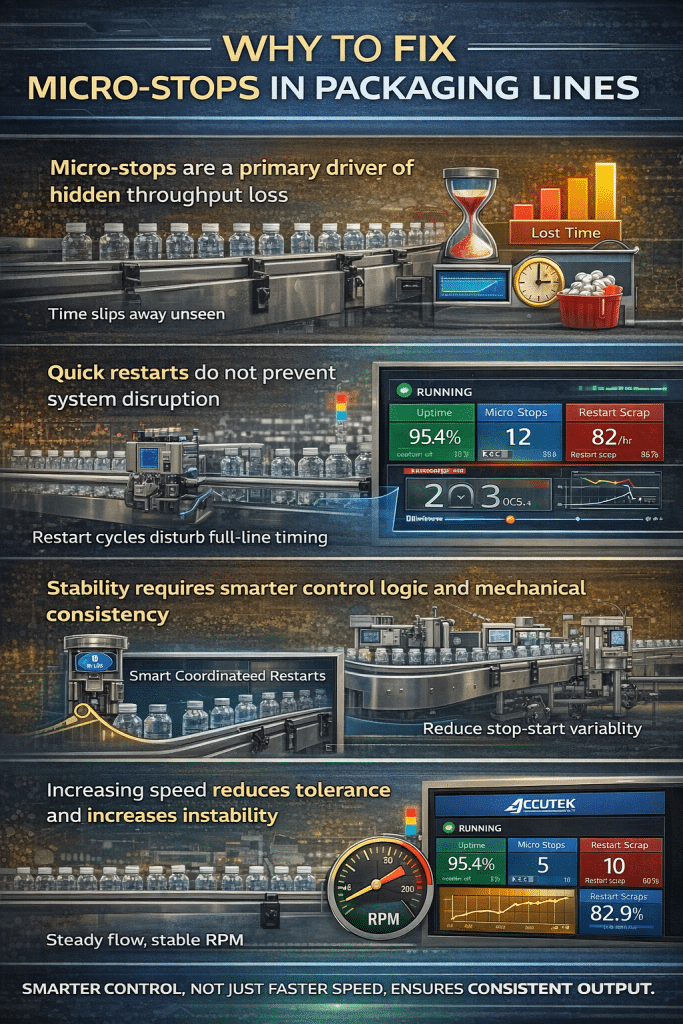

- Micro-stops are a primary driver of hidden throughput loss.

- Quick restarts do not prevent system disruption.

- Restart cycles disturb full-line timing.

- Stability requires smarter control logic and mechanical consistency.

- Increasing speed reduces tolerance and increases instability.

- Sustainable throughput comes from eliminating interruptions, not chasing RPM.

For more details contact us:

| California | Texas | Florida |

|---|---|---|

| Address: 2980 Scott St, Vista, CA 92081 | Address: 8051 Jetstar Dr #175, Irving, TX 75063 | Address: 14231 Jetport Loop W #1, Fort Myers, FL 33913 |

| Phone: (760) 734-4177 | Phone: (972) 915-6888 | Phone: (239) 225-4020 |

| Fax: (760) 734-4188 | Fax: (971) 915-6999 | Fax: (239) 225-4024 |

| Hours: 8:00 AM – 4:30 PM | Hours: 8:00 AM – 4:30 PM | Hours: 8:00 AM – 4:30 PM |