How Accutek’s Accu-Doser Series Sets the Standard for Micro-Dosing Accuracy

Precision is a non-negotiable requirement in pharmaceutical, biotech, and specialty manufacturing environments. When dealing with small-volume fills—often measured in milliliters or fractions thereof—any inconsistency can impact product performance, regulatory compliance, and overall production efficiency.

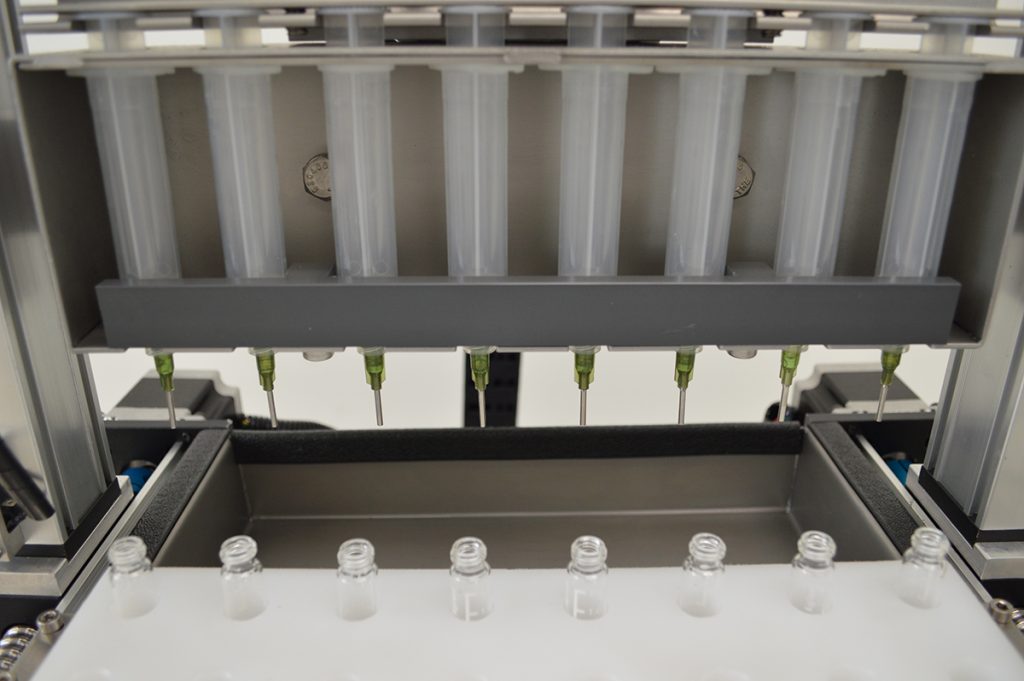

High-precision mini dose filling machines are designed to eliminate that risk. Among available solutions, Accutek’s Accu-Doser Series stands out for its ability to deliver repeatable, controlled micro-dosing while maintaining production flexibility and system integrity.

The Role of Precision in Mini Dose Filling Applications

Mini dose filling plays a critical role in industries where product value, formulation stability, and regulatory oversight demand exacting accuracy.

These applications commonly include:

- Pharmaceutical vials and injectables

- Diagnostic reagents and laboratory samples

- Cosmetic serums and specialty skincare products

- Specialty chemical formulations

At this scale, conventional filling technologies often struggle with accuracy drift, inconsistent cut-off, or excessive product loss. Precision-focused systems like the Accu-Doser are engineered to eliminate these variables.

Engineering Precision at the Core of the Accu-Doser

The Accu-Doser is built around a positive displacement dosing principle, allowing for controlled, repeatable dispensing regardless of viscosity or container size.

Key engineering characteristics include:

- Positive displacement dosing for consistent volume control

- Servo-driven or pneumatic actuation for smooth, repeatable motion

- Tool-free volume adjustments to reduce setup time

- Minimal wetted components to simplify cleaning and validation

- Compact footprint suitable for laboratory and production environments

This approach ensures accuracy remains stable across extended production runs, even in demanding operating conditions.

Performance Capabilities of the Accu-Doser Series

| Feature | Operational Benefit |

|---|---|

| Positive displacement technology | Maintains high dosing accuracy at low volumes |

| Servo-controlled motion | Improves repeatability and fill consistency |

| Quick-change tooling | Reduces downtime between product runs |

| Stainless steel construction | Supports GMP and cleanroom standards |

| Modular design | Allows integration into automated lines |

Integration Within Packaging and Production Lines

The Accu-Doser is designed for seamless integration into broader packaging systems. It functions effectively as a standalone unit or as part of a fully automated line incorporating capping, labeling, and inspection equipment.

This flexibility allows manufacturers to:

- Scale production without replacing existing equipment

- Maintain process continuity during expansion

- Align filling accuracy with downstream operations

Typical Industry Applications

| Industry | Common Use Case | Primary Benefit |

|---|---|---|

| Pharmaceuticals | Injectable vial filling | Regulatory accuracy |

| Biotechnology | Reagent and buffer dispensing | Consistent micro-dosing |

| Cosmetics | Serum and ampoule filling | Clean, repeatable fills |

| Laboratories | Sample preparation | Precision and repeatability |

| Specialty Chemicals | Controlled formulations | Reduced material waste |

Why Manufacturers Choose the Accu-Doser Platform

Accutek’s approach prioritizes engineering reliability and long-term usability rather than short-term automation gains. Manufacturers benefit from:

- Proven performance in regulated environments

- Scalable configurations to match production growth

- Engineering support and customization capabilities

- Compatibility with existing packaging infrastructure

This makes the Accu-Doser a strategic investment rather than a single-use solution.

Strategic Takeaways for Precision Filling Applications

- Designed specifically for high-precision, low-volume dispensing

- Delivers consistent results across pharmaceutical, biotech, and cosmetic use cases

- Supports scalable production without sacrificing accuracy

- Integrates easily with upstream and downstream equipment

- Backed by Accutek’s engineering expertise and manufacturing experience

For manufacturers seeking a dependable, high-precision filling solution, the Accu-Doser series offers the control, flexibility, and reliability required for modern production environments.