Every drop of product that goes to waste directly affects your bottom line, which is why precision has become the defining feature of modern filling machines.

Let’s take a closer look at the benefits of using a filler.

Why Precision Filling Matters

Whether you’re packaging beverages, cosmetics, pharmaceuticals, or cleaning solutions, the goal of any filling machine is the same: deliver the precise amount of product into each container. Inaccurate filling leads to overfills, which waste product, or underfills, which risk customer dissatisfaction.

Even small discrepancies can add up quickly. For example, overfilling by just half a milliliter per bottle can translate into thousands of lost units over a single production run. That’s why precision filling is not simply a technical detail—it’s a financial and operational necessity.

The Technology Behind Modern Filling Machines

Today’s packaging machines have come a long way from the early manual fillers that relied on operator skill and timing. Modern fillers combine mechanical design with electronic control to achieve remarkable levels of accuracy and repeatability.

Here are some of the key technologies that make precision possible:

Servo-Driven Controls

Servo motors provide precise control over piston stroke or flow rate, making each fill cycle identical. This level of control allows operators to fine-tune performance for different container sizes and product viscosities.

Flow Meters and Sensors

Advanced filling machines use mass flow or magnetic flow meters to monitor liquid movement in real time. This feedback ensures that the exact target volume is dispensed every time, regardless of temperature or density variations.

No-Drip, No-Spill Nozzle Designs

Specially engineered filling nozzles minimize product waste and mess by cutting off flow and preventing drips between fills. This is ideal for high-viscosity or sticky substances like sauces, creams, and gels.

Automated Changeover Settings

Smart filling systems can store recipes for different products or containers. Operators can switch between runs at the touch of a button, reducing downtime and maintaining consistent fill accuracy across multiple stock-keeping units.

These innovations all serve one goal: to make the filling process as efficient, clean, and profitable as possible.

How Precision Filling Reduces Waste and Costs

Every ounce of product saved means greater profits. Fillers that consistently hit the target volume minimize the overfill buffer that manufacturers often build into their processes to “stay safe.” Reducing that buffer through precision automation can significantly improve product yield.

Modern fillers can also reduce labor costs and downtime. Automated monitoring and adjustments eliminate the need for constant operator supervision. Maintenance is also simplified, as systems can self-diagnose issues before they cause costly stoppages.

Moreover, precision filling leads to uniform product presentation, which enhances brand consistency and builds consumer trust. A line of bottles or containers filled to the same level looks much more professional.

The Accutek Advantage in Precision Filling

At Accutek, we design and build filling machines that combine mechanical precision with intelligent control systems. From overflow and piston fillers to peristaltic and timed-flow models, every machine is engineered for accuracy, speed, and dependability.

Our equipment serves a wide range of industries—each with unique requirements for viscosity, container design, and fill volume. Whether you’re packaging thin liquids or thick creams, Accutek’s solutions deliver consistent performance that minimizes waste and maximizes output.

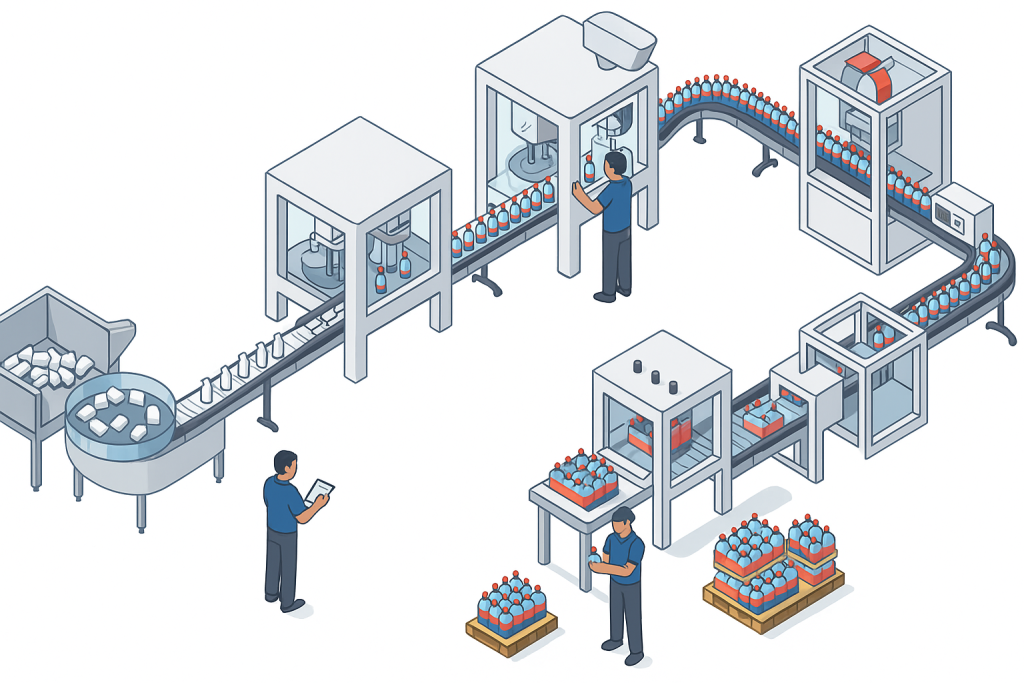

By integrating our fillers with conveyors, capping machines, and labelers, we create complete packaging systems that optimize every step of your production line. The result? Faster throughput, fewer losses, and a stronger bottom line.

By investing in advanced packaging machines from Accutek, you can reduce waste, streamline production, and ensure that every container leaving your facility meets the highest standards of quality and consistency.

Contact us so we can help you determine which of our machines would best meet your needs.