Most packaging lines do not fail because machines are too slow.

They fail because flow is unstable.

In many U.S. facilities, accumulation tables and buffer zones are added as safety measures. The assumption is simple: more buffer equals more protection.

That assumption often creates the opposite result.

Improper buffer sizing can amplify instability instead of absorbing it.

The Buffer Myth

The common belief is:

“If we add more accumulation, we protect throughput.”

In reality, accumulation is not protection by default.

It is a control mechanism.

When buffers are oversized or undersized, they distort system timing.

A packaging line is a flow network. Each machine depends on predictable spacing and controlled pressure. Accumulation must support that rhythm, not disrupt it.

Where the Assumption Breaks

Most plants size buffers using one of three methods:

- Available floor space

- Equipment vendor recommendation

- Historical guesswork

What is rarely calculated is flow variability.

Micro-stops, restart cycles, torque variation, and label hesitations all introduce timing fluctuation. If buffer capacity does not match variability amplitude, compression waves form.

Those waves move through the line.

Throughput becomes unstable.

Buffer Size vs System Behavior

| Buffer Condition | Immediate Effect | System Outcome |

|---|---|---|

| Undersized buffer | Quick fill or drain | Starvation cycles |

| Oversized buffer | Long compression zones | Delayed instability |

| Uneven buffer spacing | Irregular release | Rhythm distortion |

| No buffer between critical machines | Direct fault transfer | Cascading stops |

Buffers do not remove instability.

They redistribute it.

Engineering the Right Buffer Capacity

Effective buffer design begins with variability measurement.

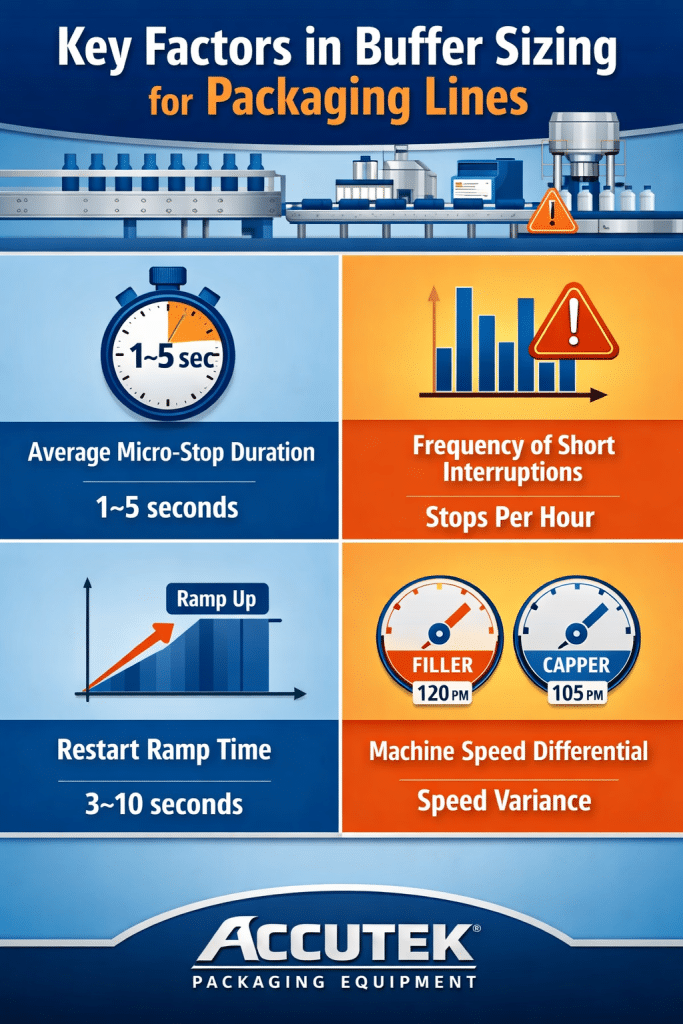

You must know:

- Average micro-stop duration

- Frequency of short interruptions

- Restart ramp time

- Machine speed differential

Without this data, accumulation sizing becomes guesswork.

The goal is not maximum storage.

The goal is absorption within tolerance.

Buffer Size vs System Behavior

| Buffer Condition | Immediate Effect | System Outcome |

|---|---|---|

| Undersized buffer | Quick fill or drain | Starvation cycles |

| Oversized buffer | Long compression zones | Delayed instability |

| Uneven buffer spacing | Irregular release | Rhythm distortion |

| No buffer between critical machines | Direct fault transfer | Cascading stops |

Buffers do not remove instability.

They redistribute it.

Engineering the Right Buffer Capacity

Effective buffer design begins with variability measurement.

You must know:

- Average micro-stop duration

- Frequency of short interruptions

- Restart ramp time

- Machine speed differential

Without this data, accumulation sizing becomes guesswork.

The goal is not maximum storage.

The goal is absorption within tolerance.

Variability Amplitude and Buffer Absorption

| Variability Type | Typical Duration | Required Buffer Response |

|---|---|---|

| Micro-stop | 1–5 seconds | Short absorption window |

| Restart ramp | 3–10 seconds | Gradual release control |

| Torque reject cycle | 2–4 seconds | Controlled compression |

| Label hesitation | 1–3 seconds | Minimal spacing shift |

Buffer length must match the disturbance window.

Too small, and the line starves.

Too large, and pressure builds slowly before releasing in waves.

The Hidden Risk of Oversized Accumulation

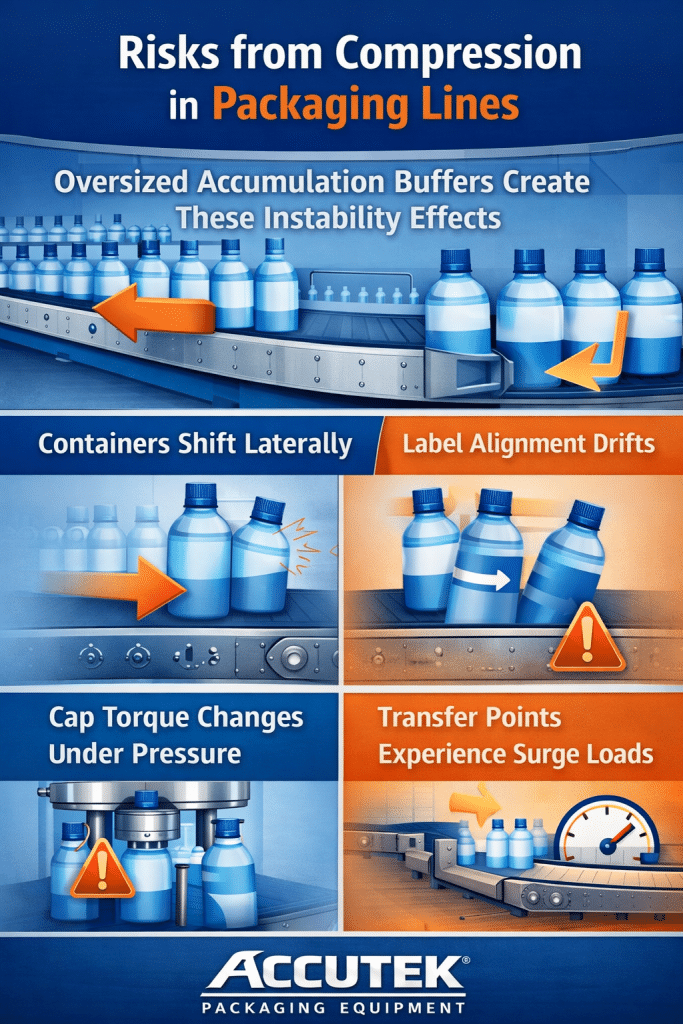

Large accumulation zones create delayed instability.

When compression builds over long conveyors:

- Containers shift laterally

- Label alignment drifts

- Cap torque changes under pressure

- Transfer points experience surge loads

The line appears stable.

Then instability releases in bursts.

This is why some high-speed lines feel unpredictable despite large buffers.

Designing for Flow, Not Storage

Modern buffer engineering focuses on:

- Controlled release logic

- Zoning with sensor feedback

- Speed synchronization

- Transfer geometry

Accutek Packaging Equipment designs integrated filling, capping, and labeling systems with matched conveyor speeds and controlled accumulation logic. When machines are engineered as a coordinated system, buffer zones act as stabilizers instead of shock amplifiers.

Integration matters more than raw length.

Control Strategy and Buffer Performance

| Control Strategy | Flow Effect | Stability Result |

|---|---|---|

| Fixed conveyor speed | Pressure builds unevenly | Instability risk |

| Zoned speed control | Gradual compression | Stable release |

| Sensor-based modulation | Real-time adjustment | Predictable flow |

| Matched machine speeds | Minimal compression | Sustained throughput |

Buffers must work with control architecture.

Mechanical length alone cannot solve instability.

Why This Matters in U.S. Manufacturing

U.S. production environments face:

- High labor cost

- Tight delivery windows

- Frequent SKU changes

- Strict quality standards

Throughput immunity reduces:

- Overtime labor

- Emergency adjustments

- Schedule volatility

- Quality variation

Stable flow improves overall profitability.

Explaining It Clearly

Think of accumulation like a shock absorber.

If the shock absorber is too stiff, every bump transfers directly to the frame.

If it is too soft, the vehicle sways and becomes unstable.

The correct buffer size absorbs disturbance without changing rhythm.

Packaging lines behave the same way.

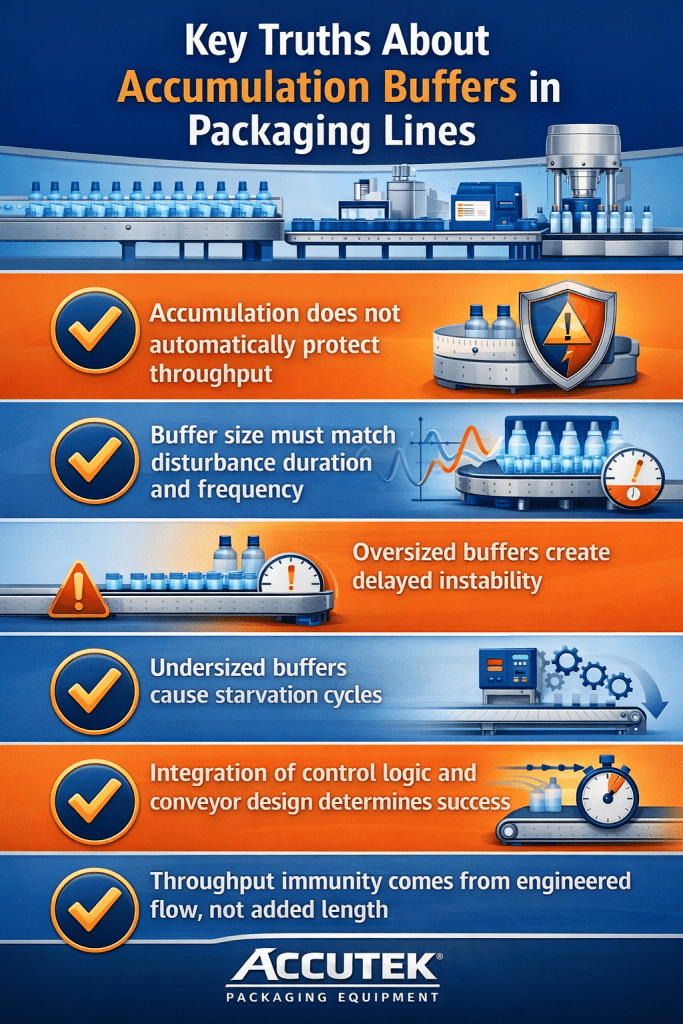

Final Perspective

- Accumulation does not automatically protect throughput.

- Buffer size must match disturbance duration and frequency.

- Oversized buffers create delayed instability.

- Undersized buffers cause starvation cycles.

- Integration of control logic and conveyor design determines success.

- Throughput immunity comes from engineered flow, not added length.

For more details contact us:

| California | Texas | Florida |

|---|---|---|

| Address: 2980 Scott St, Vista, CA 92081 | Address: 8051 Jetstar Dr #175, Irving, TX 75063 | Address: 14231 Jetport Loop W #1, Fort Myers, FL 33913 |

| Phone: (760) 734-4177 | Phone: (972) 915-6888 | Phone: (239) 225-4020 |

| Fax: (760) 734-4188 | Fax: (971) 915-6999 | Fax: (239) 225-4024 |

| Hours: 8:00 AM – 4:30 PM | Hours: 8:00 AM – 4:30 PM | Hours: 8:00 AM – 4:30 PM |