In many California manufacturing facilities, quality checks are still treated as a gate at the end of the line rather than a tool inside it. Containers move quickly, problems are detected late, and entire runs are rejected after thousands of units have already been produced.

This reactive approach feels safer — but in practice it is costly, slow, and wasteful. When inspection happens only after the fact, defects are discovered too late to prevent downtime, scrap, and schedule disruption. Modern high-volume packaging machinery requires a different mindset: inspection as real-time line intelligence, not post-production policing.

This article explains why traditional QA models struggle in California’s fast-moving packaging environments, how automated inspection changes line behavior, and what distinguishes facilities where quality protects throughput from those where it constantly interrupts it.

Why QA Matters Differently in California Manufacturing Facilities

California’s operating environment raises the stakes for quality failures.

- Stricter labeling and traceability rules increase recall exposure

- Higher labor costs make manual sorting prohibitively expensive

- Brand owners demand near-zero defect rates

- Sustainability goals penalize scrap and rework

- Complex SKU portfolios increase risk of mix-ups

Under these pressures, inspection cannot be a slow, manual backstop. It must be embedded into the line so problems are caught before they cascade into production losses.

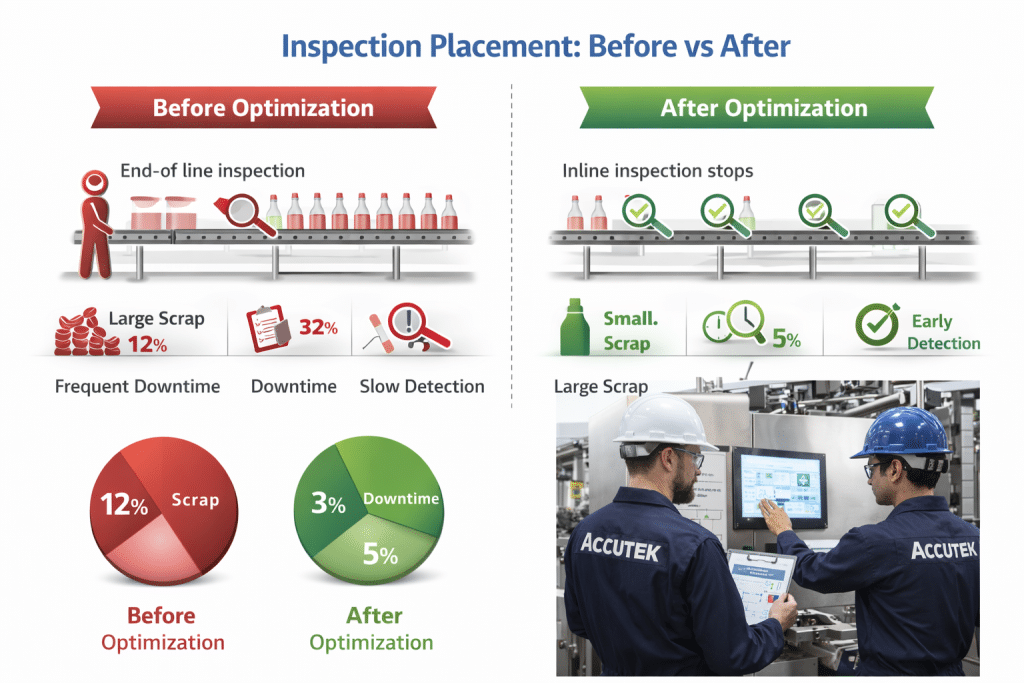

The Problem with End-of-Line Inspection

Many facilities still rely heavily on final checks after filling, capping, and labeling are complete. While this catches bad product, it does nothing to prevent the conditions that created the defect.

Typical consequences include:

- Large batches of scrap instead of isolated rejects

- Frequent line stops while defects are investigated

- Time-consuming root-cause hunts

- Operator fatigue from repetitive manual checks

In effect, end-of-line inspection treats symptoms — not causes.

Traditional vs In-Line Inspection

| Dimension | End-of-line QA | In-line automated QA |

|---|---|---|

| When defects are found | After production | During production |

| Scrap volume | Large batches | Isolated units |

| Line impact | Frequent stoppages | Continuous flow |

| Root-cause detection | Slow and reactive | Fast and data-driven |

| Labor burden | High | Low |

Where Quality Actually Breaks Down on Packaging Lines

Most defects originate in a small number of predictable places:

1) Container presentation

Misaligned bottles, unstable spacing, or orientation errors create downstream label and cap issues.

2) Fill consistency

Foaming, temperature changes, or valve wear cause drift outside tolerance.

3) Closure integrity

Improper torque or cross-threading leads to leaks, shelf-life problems, or recalls.

4) Label accuracy

Skew, missing information, or incorrect codes generate compliance risk.

Each of these failure points can be detected early — if inspection is placed in the right location.

How Automated Inspection Changes Line Behavior

When vision and sensing technologies are positioned inside the line rather than only at the end, three things happen:

- Defects are intercepted early — preventing large scrap runs

- Data becomes actionable — operators can adjust before the next defect occurs

- Flow becomes more stable — fewer emergency stops, smoother recovery

Inspection shifts from “quality policing” to “process guidance.”

How In-Line QA Protects OEE

Automated inspection improves all three OEE components simultaneously.

In-Line QA vs OEE

| QA capability | Availability | Performance | Quality |

|---|---|---|---|

| Early defect detection | Fewer unplanned stops | Consistent speeds | Lower reject rates |

| Smart reject handling | Less congestion | Steady flow | Cleaner outputs |

| Real-time feedback | Faster recovery | Tighter control | Reduced drift |

Quality stops being a drag on productivity and becomes a stabilizing force.

What Effective Packaging Inspection Looks Like

High-performing facilities in California typically deploy inspection as a layered system rather than a single checkpoint.

Common elements include:

- Fill-level verification immediately after filling

- Cap torque or closure checks before labeling

- Vision-based label verification for codes, placement, and text

- Foreign object detection where risk is highest

- Smart reject management that removes bad units without halting the line

The goal is not more checkpoints — it is better placement and smarter logic.

How Accutek Integrates QA Into Packaging Lines

Accutek Packaging Equipment Company, Inc. treats inspection as part of line architecture, not an accessory bolted on later.

Core design priorities include:

- Positioning sensors where problems first appear

- Synchronizing inspection with line speed and flow

- Using reject systems that preserve stability

- Feeding data back to controls for faster correction

Accutek QA Integration Priorities

| Design focus | Objective | Facility outcome |

|---|---|---|

| Inspection placement | Detect defects early | Smaller scrap volumes |

| Line synchronization | Match inspection to flow | Fewer false stops |

| Smart rejects | Remove bad units smoothly | Continuous production |

| Data feedback | Close the loop quickly | Faster root-cause resolution |

This approach helps California manufacturing facilities protect both quality and throughput.

Why Manual Inspection Cannot Keep Up

As speeds increase and SKUs multiply, human inspection becomes a bottleneck rather than a safeguard. Fatigue, variability, and limited visual precision make consistent detection nearly impossible.

Automation does not replace human judgment — it amplifies it by filtering routine checks and escalating only meaningful problems to operators.

Building a QA-Ready Packaging Line

Facilities planning upgrades should evaluate inspection early by asking:

- Where do most defects originate today?

- How quickly can we detect them?

- What happens to the line when a defect appears?

- Can data from inspection inform process adjustments?

If answers are vague, inspection strategy needs redesign before new packaging equipment is purchased.

Key Takeaways

- Quality is most powerful when built inside the line, not added at the end

- Early detection prevents scrap, downtime, and compliance risk

- In-line QA improves availability, performance, and quality together

- Automation stabilizes flow rather than interrupting it

- Smarter inspection is essential for high-volume California operations

For more details contact us or drop by our California office: