As manufacturers expand production capacity and diversify product lines in 2026, packaging scalability has become an essential factor in operational strategy. Scalability is not just about speed — it’s about flexibility, modular growth, consistent quality, changeover efficiency, and the ability to accommodate diverse SKUs and packaging formats without disrupting uptime.

Accutek Packaging Equipment Company, Inc., a U.S.-based manufacturer with a long history in modular packaging solutions, engineers its systems to support scalable growth — allowing manufacturers to expand throughput, adopt new container types, and optimize production lines with minimal disruption.

Why Packaging Line Scalability Matters in 2026

The global packaging landscape in 2026 presents some unique challenges and opportunities:

- Fast SKU proliferation: Brands are launching more variants, sizes, and formats.

- Omnichannel demand: Products must be labeled and packaged for multiple retail and digital channels.

- Regulatory complexity: Food, beverage, cosmetics, and pharmaceutical producers face tighter labeling and traceability standards.

- Workforce efficiency: Automation is critical to reduce labor dependency and operating costs.

In this environment, scalability is more than volume — it’s an adaptive capacity that supports business growth and market responsiveness.

Key Engineering Principles for Scalable Packaging Lines

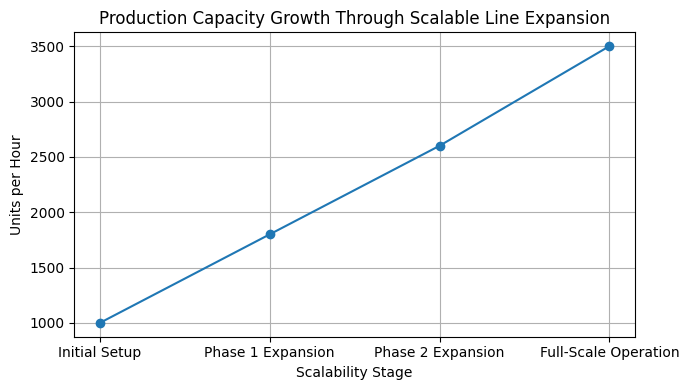

Accutek applies a set of engineering principles that allow manufacturers to scale without costly retrofits or disruptive downtime.

Modularity and Standardization

Modular design allows equipment to be deployed, reconfigured, or upgraded without replacing entire systems.

| Principle | Operational Benefit |

|---|---|

| Modular machine sections | Add or remove functions easily |

| Standardized interfaces | Interconnect conveyors, fillers, labelers |

| Plug-and-play components | Simplifies future upgrades |

This lets a bottling line, for example, start with basic labeling and later add inline inspection, rejection, and serialization modules.

Flexible Container Handling

Growing producers often serve multiple markets with different container shapes and sizes. Scalability requires:

- Adjustable guide rails

- Quick-change tooling

- Adaptive servo motion profiles

This lets a line switch from glass bottles to HDPE containers with reduced changeover ti

Flexible Container Handling

Growing producers often serve multiple markets with different container shapes and sizes. Scalability requires:

- Adjustable guide rails

- Quick-change tooling

- Adaptive servo motion profiles

This lets a line switch from glass bottles to HDPE containers with reduced changeover time.

Integrated Control and Diagnostics

2026 manufacturing environments demand connected systems with real-time visibility.

Accutek’s control architecture supports:

- Centralized HMI dashboards

- Remote diagnostics

- Automated event logging

- Predictive maintenance alerts

This allows manufacturers to identify bottlenecks and predict when upgrades are needed.

Accutek Scalability in Practice: System Examples

Below are examples of how scalable design is built into different categories of packaging equipment.

Filling Systems

| Challenge | Scalable Solution |

|---|---|

| Increased throughput | Add servo fillers or parallel filling heads |

| Viscosity variation | Volumetric, piston, and timed flow options |

| Multi-product workflow | Programmable fill profiles |

Accutek fillers are engineered to expand from low-volume startup lines to high-output production centers without fundamental redesign.

Capping and Closure Systems

| Growth Constraint | Engineered Solution |

|---|---|

| Different cap types | Interchangeable capping heads |

| Torque control precision | Adjustable torque programs |

| Line balancing with fillers | Synchronized servo control |

Scalability in capping allows lines to evolve as product lines grow more complex.

Labeling Machines

Labeling presents some of the greatest scalability challenges due to container variation and speed requirements.

| Scenario | Accutek Design Response |

|---|---|

| Multiple container shapes | Adjustable belts, sensors, guides |

| Mixed SKU batches | Programmable label recipes |

| Higher speeds | Advanced conveyor tracking |

Accutek’s labeling machines like the APS series are engineered so production can scale horizontally (more SKUs) and vertically (higher throughput).

Packaging Line Integration for Scalable Growth

Scalability is also about how machines work together. Accutek engineers packaging lines that integrate:

- Fillers

- Cappers

- Labelers

- Conveyors

- Accumulation tables

- Inspection systems

This integration reduces line interruptions and supports downstream expansion.

Scalable Line Architecture

| Line Stage | Scalable Capability |

|---|---|

| Filling | Add heads, expand capacity |

| Capping | Easy tooling changes |

| Labeling | Multi-format adaptability |

| Conveying | Adjustable speeds and buffering |

| Inspection | Add vision systems |

This architecture allows manufacturers to scale individual stages independently or as part of a full line upgrade.

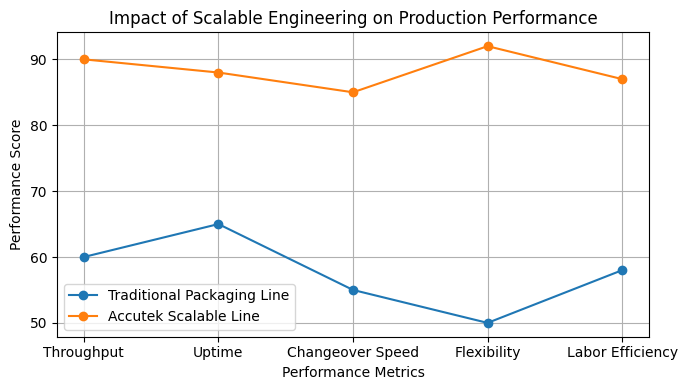

Operational Metrics That Improve with Scalability

| Metric | Impact of Scalable Engineering |

|---|---|

| Uptime | Higher with modular redundancy |

| Throughput | Incrementally increased without full line rebuilds |

| Flexibility | Faster changeovers and format switches |

| Quality | Consistent across SKUs |

| Labor | Reduced dependency through automation |

This table summarizes the measurable benefits of Accutek’s scalability engineering.

Engineering for Future-Ready Packaging in 2026

Accutek’s approach recognizes that manufacturing in 2026 is dynamic and responsive:

- Digital transformation: Labeling and packaging feedback loops connect with enterprise systems.

- Global supply chains: Scalability supports localized production and multi-site standardization.

- Consumer variety: Rapid SKU rollout requires flexible line configurations.

These trends inform how Accutek engineers its machinery and line systems.

Final Perspective

- Packaging scalability is essential for manufacturers responding to SKU diversity and market shifts

- Modular machine design supports incremental growth without major capital redesigns

- Flexible container handling and programmable controls reduce changeover time

- Integrated diagnostics and digital control enhance uptime and predictive maintenance

- Scalable line design enables staged investment aligned with business growth

Scalability engineered into packaging systems equips manufacturers to meet evolving 2026 demands — facilitating growth without sacrificing quality, compliance, or operational efficiency.