Packaging lines rarely fail all at once.

Instead, output rises and falls throughout the shift. One hour looks strong. The next hour drops. By the end of the day, production falls short of plan.

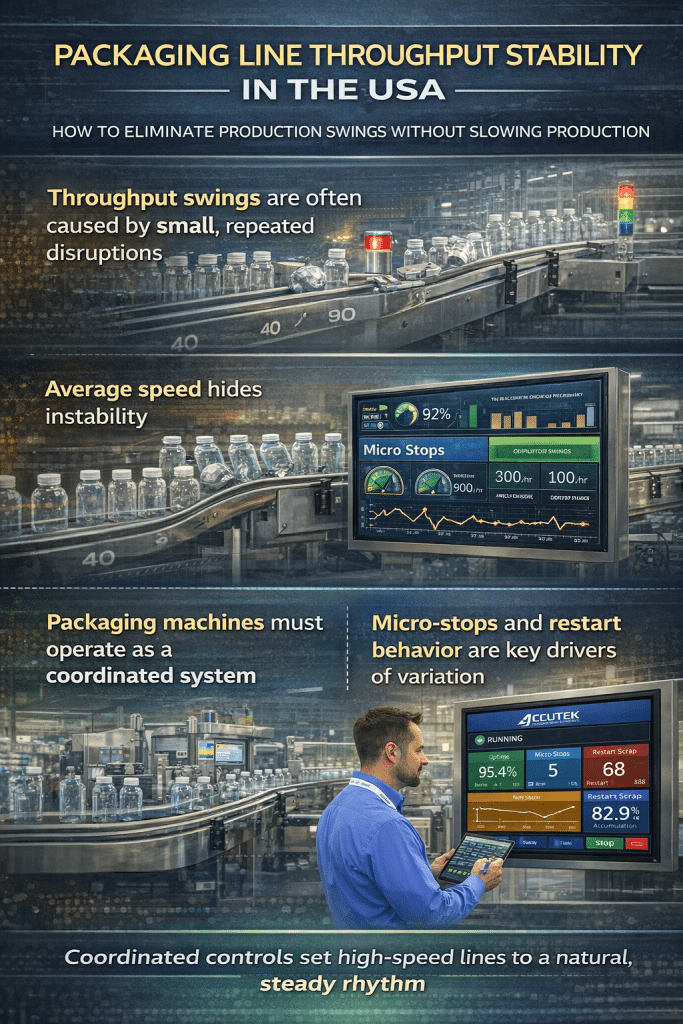

These swings are not always caused by major breakdowns. Most are small disruptions that accumulate across packaging machines.

In U.S. manufacturing, where labor, scheduling pressure, and customer expectations are high, unstable throughput creates hidden cost and risk.

This article explains why output swings happen, how they affect performance, and how better system coordination across packaging machinery can stabilize production without reducing speed.

Why throughput stability matters

Unstable output creates five business problems:

- Missed production targets

- Overtime labor

- Expedited shipping

- Inventory imbalance

- Increased scrap during restarts

When packaging machines do not run at a steady rhythm, downstream planning becomes unreliable.

Stable output is not only about speed. It is about predictability.

Where output swings begin

Most instability does not start with catastrophic failure. It begins with small variations.

Common causes include:

- Short micro-stops

- Inconsistent restart behavior

- Uneven buffer levels

- Speed mismatch between stations

- Minor sensor disruptions

Each packaging machine may run well alone. The problem appears when they operate together as a line.

Throughput instability is usually a packaging system issue, not a single-machine issue.

How small disruptions compound

| Disruption type | Frequency per shift | Time impact per event | Total impact |

|---|---|---|---|

| Micro-stops | 12 | 1 minute | 12 minutes |

| Restart scrap tuning | 4 | 3 minutes | 12 minutes |

| Buffer starvation | 5 | 2 minutes | 10 minutes |

| Sensor nuisance trips | 6 | 1 minute | 6 minutes |

Even without a major breakdown, more than 40 minutes of productive time can disappear.

This lost time rarely appears as one large downtime event. It spreads across the shift.

Why teams misread throughput data

Many dashboards show average speed.

Average speed hides variation.

If packaging machines run fast for part of the shift and slow for the rest, the average may still look acceptable.

What matters more than peak speed is consistency.

| What managers see | What is really happening |

|---|---|

| “Average 92% speed” | Output swings between 70% and 100% |

| “Downtime acceptable” | Frequent short stops disrupt rhythm |

| “No major faults” | Minor instability reduces flow |

| “Machines are fine” | System coordination is weak |

Throughput stability requires looking beyond averages.

What stable lines look like

High-performing U.S. plants share clear traits:

- Balanced speeds across packaging machines

- Controlled restart sequences

- Sufficient accumulation buffers

- Low micro-stop frequency

- Clear machine-to-line visibility

When packaging machinery runs in rhythm, output becomes predictable.

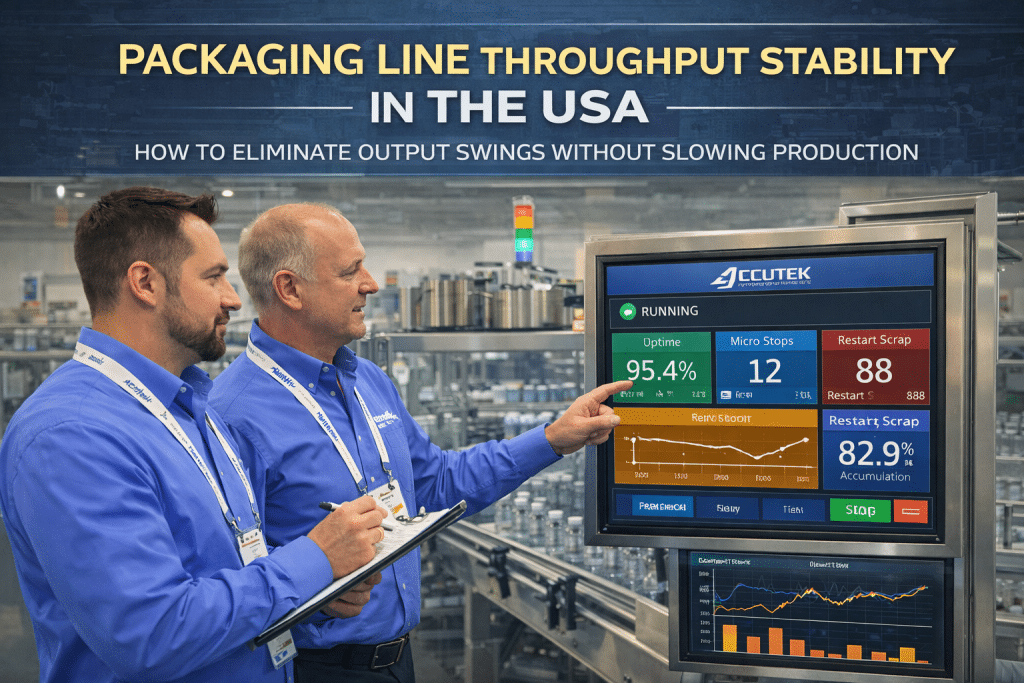

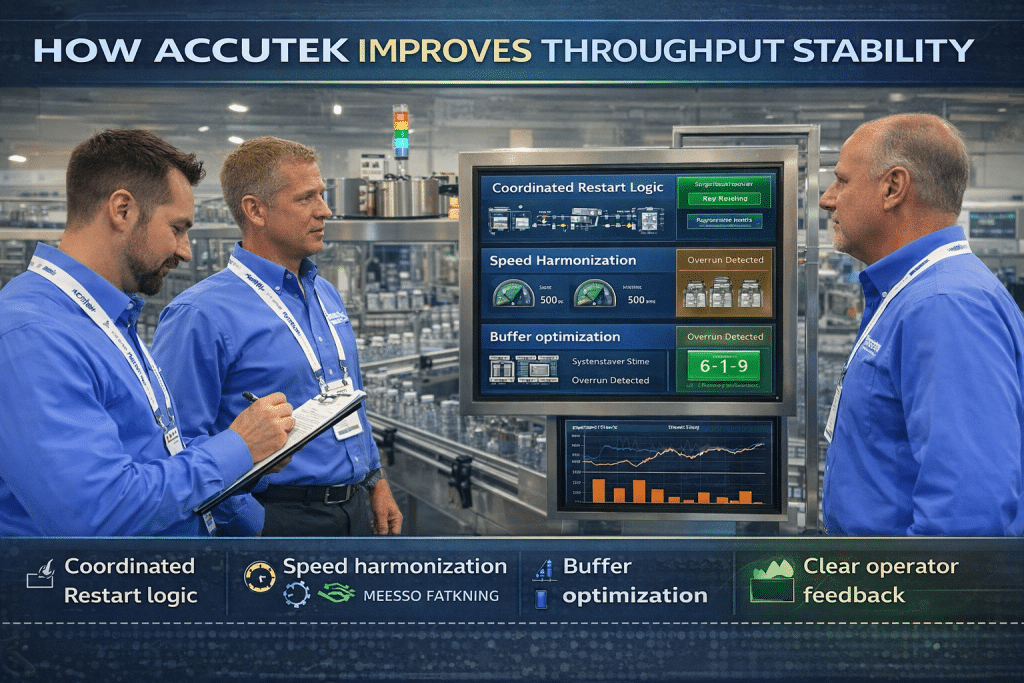

How Accutek improves throughput stability

Accutek focuses on system balance rather than isolated machine speed.

Coordinated restart logic

Accutek aligns restart timing across packaging machines so flow resumes smoothly.

Speed harmonization

Line controls help prevent one station from overrunning another.

Buffer optimization

Proper accumulation sizing reduces starvation and blocking.

Clear operator feedback

Simple status messaging reduces guesswork during minor disruptions.

Trend visibility

Monitoring micro-stops and restart performance allows plants to correct instability early.

With better coordination across packaging machinery, output becomes steady instead of erratic.

Practical stability metrics to track

Every U.S. facility should monitor:

- Micro-stops per hour

- Restart recovery time

- Speed variance across machines

- Buffer utilization trends

Tracking these consistently reveals instability before targets are missed.

From instability to predictability

Stable throughput does not require slowing packaging machines.

It requires reducing variation.

Better coordination, clearer feedback, and smarter restart behavior allow packaging machinery to run at high speed without output swings.

When production becomes steady:

- Planning improves

- Labor becomes predictable

- Scrap decreases

- Delivery performance strengthens

The result is reliable output and stronger margins.

Key takeaways

- Throughput swings are often caused by small, repeated disruptions.

- Average speed hides instability.

- Packaging machines must operate as a coordinated system.

- Micro-stops and restart behavior are key drivers of variation.

- Stable packaging machinery increases predictability and profitability.

For more details contact us:

| California | Texas | Florida |

|---|---|---|

| Address: 2980 Scott St, Vista, CA 92081 | Address: 8051 Jetstar Dr #175, Irving, TX 75063 | Address: 14231 Jetport Loop W #1, Fort Myers, FL 33913 |

| Phone: (760) 734-4177 | Phone: (972) 915-6888 | Phone: (239) 225-4020 |

| Fax: (760) 734-4188 | Fax: (971) 915-6999 | Fax: (239) 225-4024 |

| Hours: 8:00 AM – 4:30 PM | Hours: 8:00 AM – 4:30 PM | Hours: 8:00 AM – 4:30 PM |