High-speed packaging machines are often built around one overriding objective: move product as fast as possible. Only after the line is running do many facilities fully address how people interact with that speed. Guards are added late, procedures are layered on after incidents, and safety becomes something managed through training rather than designed into the system.

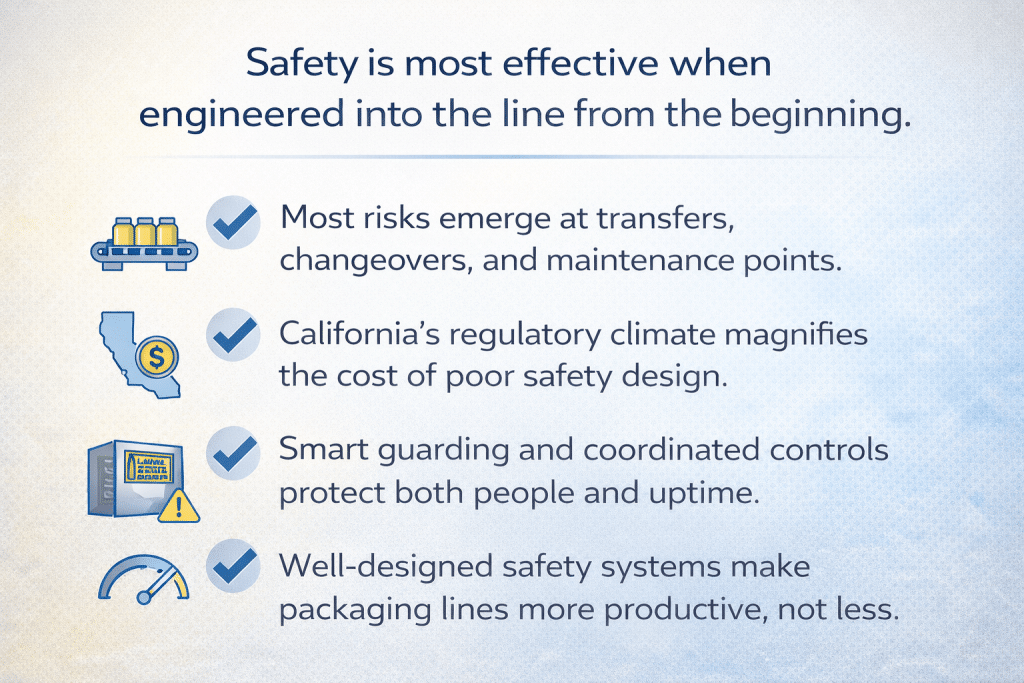

That sequence quietly embeds risk into everyday operations. When nothing goes wrong, production looks efficient. When something does go wrong, the consequences are severe: emergency stoppages, investigations, retraining, lost shifts, and schedule disruption that can ripple across an entire plant. In modern automated packaging, safety cannot be treated as a secondary concern — it must be a core engineering requirement.

This article examines why traditional, reactive safety practices struggle in high-speed packaging environments, how engineering-led risk mitigation reshapes line behavior, and what separates facilities where safety protects productivity from those where it repeatedly interrupts it.

Why Safety Carries Extra Weight in California Manufacturing

Packaging operations in California operate under conditions that make weak safety design especially costly:

- Cal/OSHA enforcement increases exposure to penalties and shutdowns.

- High labor costs amplify the impact of injuries and lost shifts.

- Highly automated lines introduce new types of mechanical and electrical risk.

- Complex product portfolios require frequent adjustments and interventions.

- Brand and recall sensitivity raises the stakes of operational incidents.

In this environment, safety must do more than satisfy minimum compliance — it must reduce risk through thoughtful machine and line design.

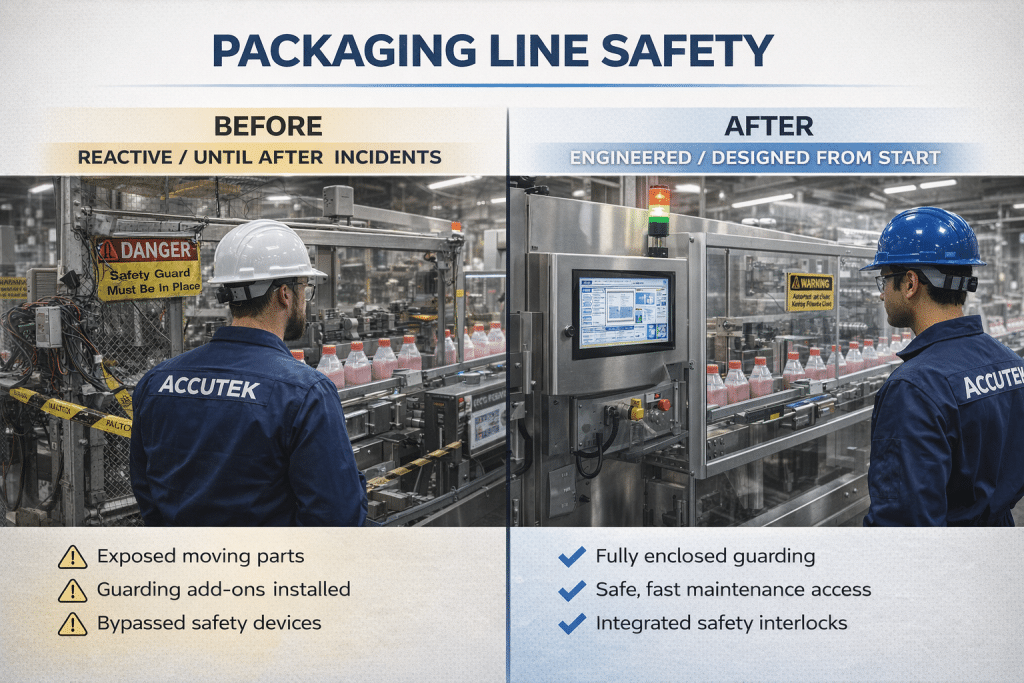

The Problem with After-the-Fact Safety

Many facilities still approach safety reactively, retrofitting protections only after equipment is installed or an incident occurs. While this may satisfy basic requirements, it rarely produces truly safe or efficient operations.

Common outcomes include:

- Guards that block visibility or maintenance access.

- Operators bypassing safety devices to keep the line moving.

- Frequent emergency stops that disrupt production.

- Longer troubleshooting cycles due to poorly integrated safeguards.

In practice, reactive safety treats symptoms rather than root causes.

Reactive vs Engineered Safety

| Dimension | Reactive safety | Engineered safety |

|---|---|---|

| When safety is considered | After installation | During line design |

| Guard placement | Improvised | Purpose-built |

| Operator behavior | Workarounds common | Safer defaults |

| Downtime impact | High | Low |

| Compliance risk | Variable | Consistently lower |

Where Risk Most Commonly Emerges on Packaging Lines

Safety hazards tend to cluster around predictable points in the process rather than appearing randomly.

1) Infeeds and transfers

Manual interventions most often occur where containers enter or move between machines.

2) Changeovers and adjustments

Risk spikes when operators reach into equipment to clear jams, realign bottles, or swap formats.

3) Maintenance access

Poorly designed layouts force technicians into awkward or unsafe positions.

4) Emergency stops and recovery

Uncoordinated shutdowns and restarts increase the likelihood of accidental exposure to moving parts.

These risks are shaped by how the line is engineered — not just by operator behavior.

How Engineering-Led Safety Changes Line Behavior

When safety is embedded into machine and line design from the start, three changes typically occur:

- Fewer emergency interventions — better flow means fewer manual corrections.

- Safer, faster maintenance — designed access reduces both risk and downtime.

- Predictable shutdowns and restarts — fewer chaotic moments where injuries occur.

Safety shifts from being a constraint to becoming a stabilizing force.

How Safety Design Supports OEE

Well-engineered safety systems can improve availability, performance, and quality at the same time.

Safety design vs OEE

| Safety feature | Availability | Performance | Quality |

|---|---|---|---|

| Smart guarding | Fewer unplanned stops | Consistent speeds | Less process drift |

| Safe access points | Faster repairs | Steadier flow | Lower restart scrap |

| Coordinated E-stops | Shorter recovery | Stable ramp-up | Reduced defects |

When controls and safeguards are aligned, lines run more reliably — not less.

What Effective Packaging Line Safety Looks Like

High-performing facilities in California tend to integrate safety across four dimensions:

- Risk-aware layout — clear operator pathways and safe reach zones.

- Integrated guarding — transparent barriers that protect without obstructing.

- Smart interlocks — machines pause safely without forcing full shutdowns.

- Controlled recovery — coordinated restarts that minimize exposure.

The goal is not more barriers, but better-placed, smarter protections.

How Accutek Engineers Safety Into Packaging Systems

Accutek Packaging Equipment Company, Inc. treats safety as a core design requirement rather than a compliance checkbox.

Key priorities include:

- Designing guards that preserve visibility and access.

- Locating controls within safe reach zones.

- Using interlocks that prevent hazardous motion during service.

- Coordinating safety logic with line controls for smooth recovery.

Accutek safety design priorities

| Design focus | Objective | Facility outcome |

|---|---|---|

| Guard design | Protect without obstructing | Safer operation |

| Access planning | Reduce risky reach | Faster maintenance |

| Smart interlocks | Prevent unsafe motion | Fewer incidents |

| Coordinated controls | Safe restarts | Less downtime |

This approach helps California manufacturing facilities maintain both safety and throughput.

Why Training Alone Is Not Enough

Training is essential — but it cannot compensate for poor machine design. Even the most skilled operators will take shortcuts if equipment is difficult or unsafe to work with.

Good engineering makes safe behavior the easy behavior.

Building a Safer Packaging Line

Facilities planning upgrades should evaluate safety early by asking:

- Where do operators most frequently intervene today?

- How easy is it to access critical components safely?

- What happens during emergency stops?

- How does the line restart after a fault?

If these questions are difficult to answer, safety strategy needs redesign before new equipment is purchased.

For more details contact us or drop by our California office: