In many California manufacturing facilities, packaging systems appear rock-solid at today’s production levels yet become strained the moment volumes rise. A line that performs smoothly during a single shift can feel overloaded when demand increases, product formats change, or schedules compress.

This breakdown is rarely caused by faulty equipment. More often, it reflects a line designed around current throughput rather than future expansion. When packaging machinery is configured only for present-day targets, growth introduces congestion, uneven flow, and mounting downtime that operations teams struggle to control.

This article examines why scalability failures repeatedly surface in California operations, how they manifest on the floor, and what distinguishes packaging systems that grow gracefully from those that fracture under pressure.

Why Scalability Matters So Much in California Manufacturing Facilities

The operating climate in California magnifies the cost of weak scalability.

- Elevated labor expenses make every bottleneck expensive

- Regulatory scrutiny limits quick fixes when problems arise

- Frequent product launches and private-label programs drive constant SKU churn

- Sustainability commitments increase sensitivity to scrap and rework

Under these conditions, packaging machinery cannot be tuned only for today’s run rate. It must be built to absorb higher volumes, new formats, and shifting product mixes without destabilizing operations.

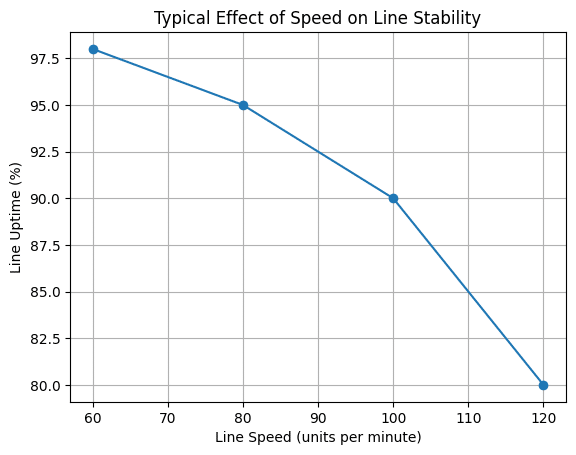

The Gap Between “Fast Today” and “Built to Grow”

Many lines perform impressively at a single operating point. They run cleanly at one speed, with one container, and one product profile — but become unstable as soon as conditions shift.

Warning signs that a line is fast but not scalable include:

- More jams as speeds climb

- Constant retuning after minor format changes

- Longer recovery windows after brief interruptions

- Supervisors actively “managing” product flow rather than supervising it

Speed is a snapshot in time. Scalability is endurance across changing conditions.

Fast vs. Scalable Packaging Lines

| Attribute | Fast Line | Scalable Line |

|---|---|---|

| Operating range | Narrow sweet spot | Broad performance band |

| Reaction to disruption | Easily destabilized | Naturally resilient |

| Operator workload | Constant intervention | Light supervision |

| Growth path | Major rebuild needed | Incremental upgrades |

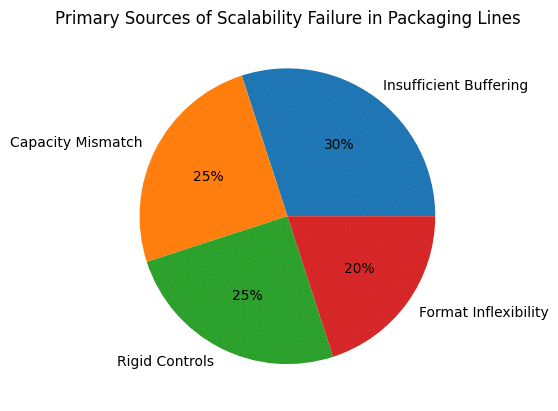

Where Scalability Typically Fails

1) Limited buffering

Lines built too tightly leave no room to absorb variability. At higher speeds, small hiccups cascade into full shutdowns.

2) Mismatched machine capacity

When equipment is added piecemeal over time, upstream and downstream capabilities rarely align, creating chronic choke points.

3) Rigid control frameworks

Fragmented or outdated controls struggle to coordinate faster, more complex operations.

4) Format inflexibility

Systems optimized around one bottle shape or label format resist change, making every new SKU feel like a major project.

These weaknesses are often invisible at low volumes but dominate performance at scale.

How Scalability Shapes OEE and Reliability

Weak scalability undermines availability, performance, and quality simultaneously.

Scalability vs OEE Impact

| Scalability gap | Availability effect | Performance effect | Quality effect |

|---|---|---|---|

| Insufficient buffering | More stoppages | Forced slowdowns | Startup defects |

| Poor capacity balance | Longer downtime | Uneven speeds | Label drift |

| Rigid formats | Extended changeovers | Lower averages | Higher scrap |

Strong scalability lifts all three pillars together rather than forcing tradeoffs.

What Genuine Scalability Looks Like

A truly scalable packaging system tends to share four characteristics:

- Adaptive flow control — accumulation expands as demand rises

- Balanced machine capacity — no single chronic bottleneck

- Coordinated controls — the line behaves as one system

- Format agility — predictable transitions between SKUs

When these elements are present, growth feels manageable rather than chaotic.

How Accutek Engineers Scalable Systems in California

Accutek Packaging Equipment Company, Inc. treats scalability as a line-design challenge, not a machine-purchasing decision.

Core design priorities include:

- Generous, intelligent accumulation rather than compressed layouts

- Capacity balancing based on real production data, not nameplate speeds

- Control architectures that orchestrate the entire line

- Modular layouts that allow incremental expansion

Accutek Scalability Design Priorities

| Design focus | Objective | Facility outcome |

|---|---|---|

| Buffering | Absorb variability | Fewer shutdowns |

| Capacity balance | Match true operating speeds | Steady flow |

| Controls | Line-wide coordination | Predictable behavior |

| Layout | Modular expansion | Lower upgrade cost |

This approach enables manufacturing facilities to grow without dismantling what already works.

Why Retrofitting Scalability Is Difficult

Many manufacturing facilities attempt to scale after the fact by adding equipment, widening conveyors, or pushing speeds higher — while leaving the underlying architecture unchanged.

Typical retrofit pitfalls include:

- Adding capacity where it is not actually needed

- Creating new downstream bottlenecks

- Increasing complexity without improving coordination

- Making changeovers slower instead of faster

It is usually more effective — and cheaper — to design for scalability from the start.

Designing Lines That Can Grow With You

Organizations planning expansion should stress-test scalability before purchasing equipment by asking:

- Can this line handle 20–40% higher speed?

- What happens if one station stops for 30 seconds?

- How easily can we introduce new SKUs?

- Will controls still function smoothly with additional devices?

If these questions are hard to answer, the system is likely not truly scalable.

Key Takeaways

- Speed today does not equal scalability tomorrow

- Growth failures usually emerge at machine handoffs, not inside equipment

- California’s operating conditions amplify the cost of weak scalability

- Buffering, capacity balance, and coordinated controls are the foundation of growth

- Designing for scalability protects uptime, quality, and capital investment

For more details contact us or drop by our California office: