Engineering Controls That Protect Seal Integrity for U.S. and California Manufacturers

Cap cross-threading is one of the most damaging and expensive defects in bottling operations. It leads to leaking product, rejected batches, customer complaints, and in regulated industries, potential compliance issues. For many manufacturers, especially in California’s food, beverage, personal care, and chemical sectors, seal integrity is not optional—it is part of regulatory and brand protection.

In packaging machinery, cap cross-threading occurs when the cap and container threads fail to align properly before torque is applied, causing the closure to bind, seat unevenly, or damage the threads. While cap quality matters, cross-threading is most often the result of machine alignment, container handling, and torque control problems.

This article explains why cross-threading occurs, where common explanations fall short, and how properly engineered packaging machines prevent the defect at the source.

Why Cross-Threading Is Usually a Machine Handling Problem

Many operations respond to cross-threading by changing cap suppliers or tightening incoming inspections. While this can reduce extreme defects, it rarely eliminates the problem entirely.

Cross-threading increases when:

- Containers enter the capping zone unstable or off-center

- Caps are not oriented consistently before placement

- Application heads apply torque before threads are fully engaged

- Bottles rotate or tilt during cap engagement

All of these are packaging machine control issues, not raw material defects.

If the machine cannot stabilize, align, and sequence cap engagement correctly, even high-quality closures will cross-thread.

Where Common Explanations Break Down

Cross-threading is frequently misdiagnosed, which leads to fixes that treat symptoms instead of root causes.

Common Beliefs vs. Engineering Reality

| Common Belief | What’s Actually Causing the Defect |

|---|---|

| “The caps are bad” | Caps are often within spec; misalignment occurs during application |

| “Operators need to be more careful” | Machines lack mechanical guides and stabilization |

| “Increase torque” | Excess torque damages threads once misalignment occurs |

| “Slow the line down” | Speed reveals instability but doesn’t create it |

Without correcting mechanical alignment and torque sequencing, cross-threading will persist even at lower speeds.

Engineering Controls That Prevent Cross-Threading

Preventing cross-threading requires controlling three variables at the same time:

- Cap orientation

- Container stability

- Torque application sequence

Machine Features That Reduce Cross-Threading Risk

| Engineering Feature | Why It Matters |

|---|---|

| Cap orientation and delivery control | Ensures caps approach threads correctly |

| Side-grip or top-hold bottle stabilization | Prevents bottle movement during engagement |

| Floating or spring-loaded spindles | Allows caps to self-center on threads |

| Servo or clutch-regulated torque | Applies force only after proper engagement |

| Adjustable capping components | Supports different closure geometries accurately |

These features allow the cap to seat naturally before tightening, instead of being forced into place.

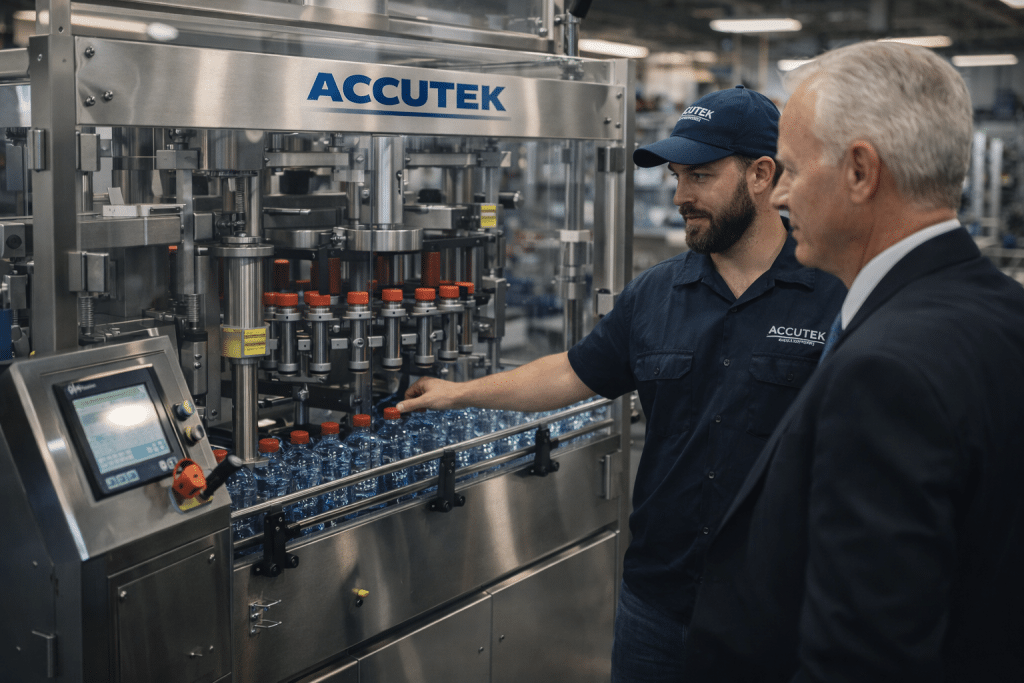

Accutek Capping Machines Designed to Prevent Cross-Threading

Accutek manufactures several capping platforms that address the mechanical causes of cross-threading through controlled handling and torque application—important for U.S. manufacturers operating under quality and compliance expectations.

Spindle Capping Systems

Accutek’s automatic spindle cappers use synchronized spinning belts that gradually seat threaded closures while stabilizing the container. This reduces sudden torque application that can damage threads.

Best suited for:

- Plastic and lightweight containers

- Wide ranges of cap sizes

- High-speed beverage and personal care lines

Gradual engagement allows threads to align before full seating force is applied.

Chuck Capping Machines

Accutek’s chuck cappers physically grip the closure during application, providing highly controlled torque and alignment.

Best suited for:

- Taller or heavier containers

- Metal or specialty closures

- Applications requiring precise torque consistency

Because the closure is mechanically held, thread engagement is more controlled, reducing cross-thread risk.

Snap and Belt-Driven Capping Systems

For snap-on or specialty closures, Accutek’s belt-driven snap cappers apply uniform downward pressure while maintaining container stability.

Best suited for:

- Push-fit caps

- Child-resistant designs

- Specialty cosmetic packaging

Consistent downward force and container control prevent uneven seating that can mimic cross-thread defects.

Why Container Handling Is Just as Important as the Capper

Even the most precise capping head cannot compensate for unstable containers.

Cross-threading increases when:

- Bottles tilt under pressure

- Containers arrive at inconsistent spacing

- Conveyor vibration disrupts engagement

Well-engineered packaging machines include:

- Infeed timing controls

- Bottle centering guides

- Side-grip or overhead stabilization during capping

In many cases, improving container handling upstream eliminates cross-threading without changing capping heads at all.

Why Increasing Torque Makes the Problem Worse

Applying more torque does not correct misalignment—it only forces damaged threads together.

Higher torque:

- Masks alignment problems temporarily

- Increases permanent thread deformation

- Makes consumer opening more difficult

- Leads to inconsistent seal integrity

Effective packaging machines apply just enough torque, only after proper thread engagement, not as a substitute for alignment.

Solving Cross-Threading at the Line Level, Not Just at the Capper

Cross-threading is often the result of system-level instability, not a single component failure.

Line Factors That Contribute to Threading Defects

| Line Component | How It Affects Capping Accuracy |

|---|---|

| Conveyors | Poor spacing disrupts engagement timing |

| Bottle unscramblers | Inconsistent orientation entering the line |

| Labelers | Bottle contact can alter alignment before capping |

| Accumulation zones | Sudden pressure changes affect stability |

Packaging machine solutions must evaluate the entire container path, not just the capping station.

Why Caps Cross-Thread in Simple Terms

Caps cross-thread when the machine tightens them before they are lined up correctly.

If a bottle is moving, tilted, or off-center, and the cap is twisted too soon, the threads collide instead of engaging. Once damaged, no amount of torque will fix the alignment.

Packaging machines must:

- Hold the bottle steady

- Place the cap straight

- Let threads engage naturally

- Then apply controlled torque

When that sequence is respected, cross-threading largely disappears.

Engineering Eliminates Cross-Threading at the Source

- Cross-threading is primarily a machine alignment and stabilization problem

- Proper cap orientation and container handling are critical

- Torque must follow thread engagement, not replace it

- Accutek spindle, chuck, and snap capping systems are engineered to control these variables

- System-level line balance prevents recurring closure defects

For California and U.S. manufacturers, eliminating cross-threading is not about blaming caps—it is about choosing packaging machines engineered to align, stabilize, and engage closures correctly every time.