Across California’s industrial corridor, sustainability has shifted from a marketing theme to an operational requirement. Food, beverage, cosmetics, chemical, and pharmaceutical producers are under simultaneous pressure to lower emissions, reduce scrap, conserve energy, and maintain tight production economics. In this environment, packaging machinery is no longer judged only by speed or uptime — it is evaluated by its environmental footprint.

Yet many facilities pursue sustainability in fragmented ways: a recycling initiative here, an energy audit there, a scrap-reduction project somewhere else. The result is often incremental gains without meaningful system-wide impact. Real progress requires treating sustainability as a line-design problem, not a series of isolated improvements.

This article examines how packaging systems create waste in everyday operation, why some efficiency initiatives fail, and what distinguishes truly sustainable packaging lines from those that merely appear “green.”

Why Sustainability Hits Harder in California Manufacturing Facilities

California’s regulatory landscape, utility pricing, and consumer expectations intensify the cost of inefficiency.

- Tiered electricity rates make peak power demand expensive

- Strict waste diversion rules raise landfill costs

- Extended Producer Responsibility (EPR) policies increase scrutiny on packaging materials

- Retail and brand owners demand lower carbon intensity from suppliers

In this context, packaging machinery must do more than produce units — it must minimize resource consumption, avoid scrap, and support circular material flows.

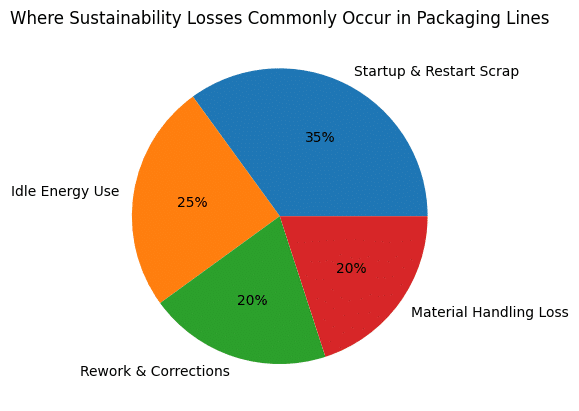

Where Packaging Lines Actually Generate Waste

Most waste does not occur during steady-state production. It emerges during transitions, instability, and poor coordination.

Material waste appears when:

- Containers are misaligned or misfed

- Labels are skewed or misapplied

- Caps are over- or under-torqued

- Fill levels drift outside tolerance

Energy waste appears when:

- Machines idle at high power during stoppages

- Conveyors run continuously without smart control

- Compressors cycle inefficiently

- Heating systems stay on between shifts

Labor waste appears when:

- Operators manually correct flow problems

- Maintenance teams perform repeated emergency fixes

- Changeovers are slow and error-prone

Sustainability is therefore as much about stable operations as it is about materials or technology.

The Gap Between “Eco-Friendly Machines” and Sustainable Lines

Many buyers select packaging equipment labeled as “energy-efficient” or “low-waste,” yet still struggle to meet sustainability goals. The reason is simple: efficient machines do not guarantee an efficient system.

Machine-Level vs System-Level Sustainability

| Dimension | Machine-focused approach | System-focused approach |

|---|---|---|

| Energy use | Low-power motors | Smart line-wide power control |

| Scrap reduction | Better applicators | Stable container flow |

| Material efficiency | Thinner labels | Fewer reworks and restarts |

| Labor efficiency | Automation per station | Coordinated line behavior |

| Results | Local gains | Measurable footprint reduction |

True sustainability emerges when the entire line is engineered to minimize waste, not just individual devices.

How Instability Undermines Sustainability

Every unplanned stop increases environmental impact. Restart cycles consume extra energy, create scrap, and disrupt material flow.

Common triggers include:

- Poor accumulation that forces full-line shutdowns

- Speed mismatches that cause jams and misfeeds

- Fragmented controls that prevent smooth recovery

- Rigid formats that generate scrap during changeovers

When lines are stable, sustainability metrics improve automatically.

What a Sustainable Packaging Line Looks Like

High-performing facilities in California share four characteristics:

- Predictable flow control — fewer jams mean less scrap

- Balanced capacity — avoids wasteful throttling and idling

- Smart energy management — machines power down when idle

- Format agility — reduces scrap during SKU transitions

Sustainability becomes a byproduct of good engineering.

How Accutek Designs for Sustainability in California

Accutek Packaging Equipment Company, Inc. treats environmental performance as a line-design principle rather than a bolt-on feature.

Core priorities include:

- Right-sized accumulation to prevent scrap-inducing stoppages

- Speed coordination that reduces unnecessary idling

- Control architectures that enable intelligent power states

- Changeover-friendly layouts that minimize wasted product

Accutek Sustainability Design Priorities

| Design focus | Objective | Environmental outcome |

|---|---|---|

| Flow stability | Fewer interruptions | Less scrap |

| Capacity balance | Reduce idle time | Lower energy use |

| Smart controls | Automated sleep modes | Smaller carbon footprint |

| Modular layout | Faster changeovers | Less wasted material |

This approach helps California manufacturing facilities cut waste while maintaining productivity.

Why Recycling Alone Is Not Enough

Many sustainability programs overemphasize end-of-life recycling while ignoring operational waste. While recycling is important, the larger gains typically come from:

- Preventing scrap before it is created

- Avoiding unnecessary energy use

- Reducing labor-intensive rework

- Designing lines that run cleanly at scale

The most sustainable package is the one that never becomes waste in the first place.

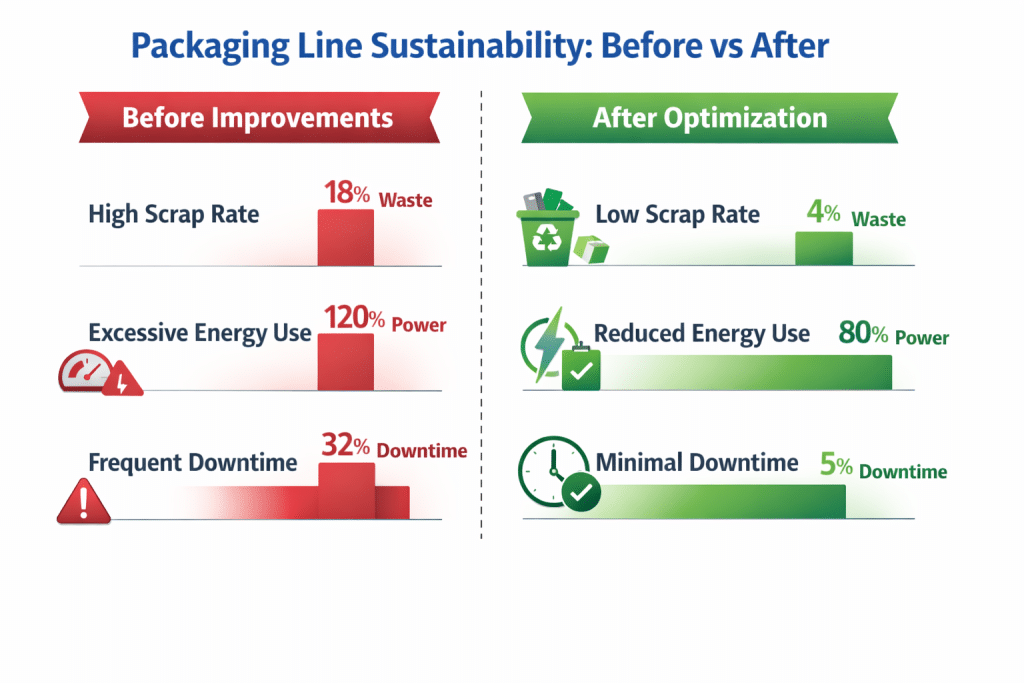

Measuring What Matters

Facilities serious about sustainability should track:

- Scrap rate per shift

- Energy use per thousand units

- Downtime-driven waste

- Changeover scrap volume

- Compressed air and heating demand

When these metrics improve together, the line is becoming genuinely sustainable.

Building a Lower-Impact Packaging System

Manufacturers planning upgrades should evaluate sustainability early by asking:

- How much scrap is generated during restarts?

- What happens to energy use during stoppages?

- How much material is lost in changeovers?

- Can controls reduce power automatically?

If answers are unclear, sustainability gains will likely be limited.

Key Takeaways

- Sustainability is a system issue, not a single-machine feature

- Most waste stems from instability, not materials alone

- California’s policies and energy costs magnify inefficiency

- Stable, well-coordinated lines are inherently more sustainable

- Engineering for reliability is one of the best environmental strategies

For more details contact us or drop by our California office: