Material waste in packaging lines rarely explodes into a crisis. It usually builds slowly in bins of rejected bottles, crooked labels, and product that must be dumped after a bad fill.

Each loss looks small by itself. Together, these losses cut into profit.

Many plants still treat scrap as the price of running fast. Crews chase speed while accepting waste as normal. Across the United States, this habit raises costs, adds compliance risk, and weakens sustainability goals.

This article explains where packaging material waste really comes from, why it persists on modern packaging machines, and how better line design can cut scrap on packaging machinery without slowing production.

Why material waste matters in the USA

Material waste is more than an environmental issue. It is a financial and operational risk.

In U.S. plants:

- Labor is expensive.

- Disposal rules are tightening.

- Brands face growing sustainability pressure.

When scrap rises, total costs rise even faster.

Most waste does not start with bad materials. It starts with how the line behaves during real production.

Where packaging waste usually begins

1) Unstable infeed

Uneven bottle spacing or tipping disrupts filling and labeling downstream.

2) Fill instability

Pressure swings or pump drift create overfills and underfills that must be dumped.

3) Label problems

Wrinkled or crooked labels often force relabeling or scrap.

4) Changeovers

New SKUs usually create waste until the line stabilizes.

5) Restarts

Every stop and restart creates a short burst of defects packaging machines.

A few rejects per hour may look minor. Over a full shift, they add up to major losses.

How small waste events become big losses

One rejected bottle feels small. Hundreds per shift are not.

How scrap compounds in one shift

| Waste source | Frequency | Scrap per event | Total scrap |

|---|---|---|---|

| Label misalignment | 6 per hour | 3 bottles | 144 bottles |

| Fill drift rejects | 4 per hour | 2 bottles | 96 bottles |

| Restart defects | 5 per hour | 4 bottles | 160 bottles |

| Total lost units | — | — | ~400 bottles |

Most plants never classify this as “material loss,” yet it is real money.

Why teams misdiagnose scrap

Many teams blame materials or operators when scrap rises. This usually misses the true cause.

In practice, scrap most often comes from:

- Unstable flow

- Weak restart behavior

- Poorly matched packaging machinery speeds

Fixing materials or retraining people rarely solves these problems.

Common assumptions vs reality

| Common belief | What usually causes waste |

|---|---|

| “The labels are bad.” | Inconsistent bottle speed |

| “The filler is inaccurate.” | Pressure swings after stops |

| “Operators made mistakes.” | Poor machine feedback |

| “We need better material.” | We need better flow control |

How line design creates — or prevents — waste

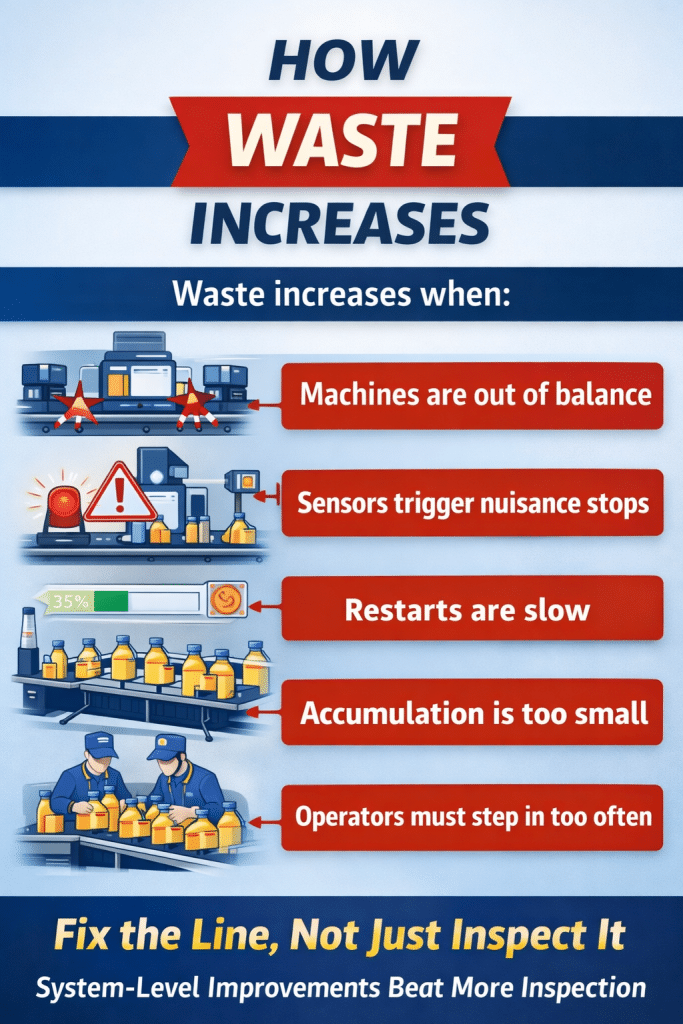

Scrap rises when packaging machinery is poorly coordinated.

Waste increases when:

- Machines are out of balance

- Sensors trigger nuisance stops

- Restarts are slow

- Accumulation is too small

- Operators must step in too often

Waste falls when the line runs smoothly, predictably, and in sync from start to finish.

What low-waste lines look like

Low-waste facilities share four traits:

- Stable container flow

- Consistent filling

- Accurate labeling

- Fast, coordinated restarts

These plants treat waste as preventable, not inevitable.

How Accutek helps cut material waste

Accutek Packaging Equipment Company, Inc. treats material waste as a system problem, not a machine problem. The company designs packaging machines to reduce scrap where it most often begins.

Cleaner infeed handling

Accutek builds smoother infeed systems to keep bottles aligned and spaced correctly. Better spacing means fewer downstream defects.

More stable filling

Accutek filling platforms limit pressure swings and fill drift. This reduces the number of containers that must be dumped or refilled.

Faster label recovery

Accutek labeling systems recover quickly after stops or changeovers. Faster recovery means fewer bad labels at startup.

Coordinated restarts

Accutek aligns restart logic across all packaging machinery instead of treating machines separately. This shortens the unstable window after stops and reduces scrap bursts.

Line-wide tuning

Accutek tunes the entire line as one system. By balancing real speeds, improving accumulation, and cutting nuisance stops, plants often reduce waste without lowering line speed.

Accutek approach vs waste drivers

| Waste driver | Accutek response | Facility result |

|---|---|---|

| Tipped bottles | Better handling | Fewer rejects |

| Fill drift | Smarter controls | Less dumping |

| Label errors | Fast recovery | Less relabeling |

| Restart scrap | Coordinated logic | Cleaner runs |

Why “inspect more” is not enough

Adding more inspection may catch more defects, but it does not remove their causes.

A stronger approach focuses on:

- Reducing variability

- Improving stability

- Speeding up restarts

- Preventing waste before it occurs

What to measure instead

To reduce waste, plants should track four things:

- Scrap per hour by cause

- Scrap after restarts

- Fill variation over time

- Label accuracy after changeovers

When these improve together, material waste falls.

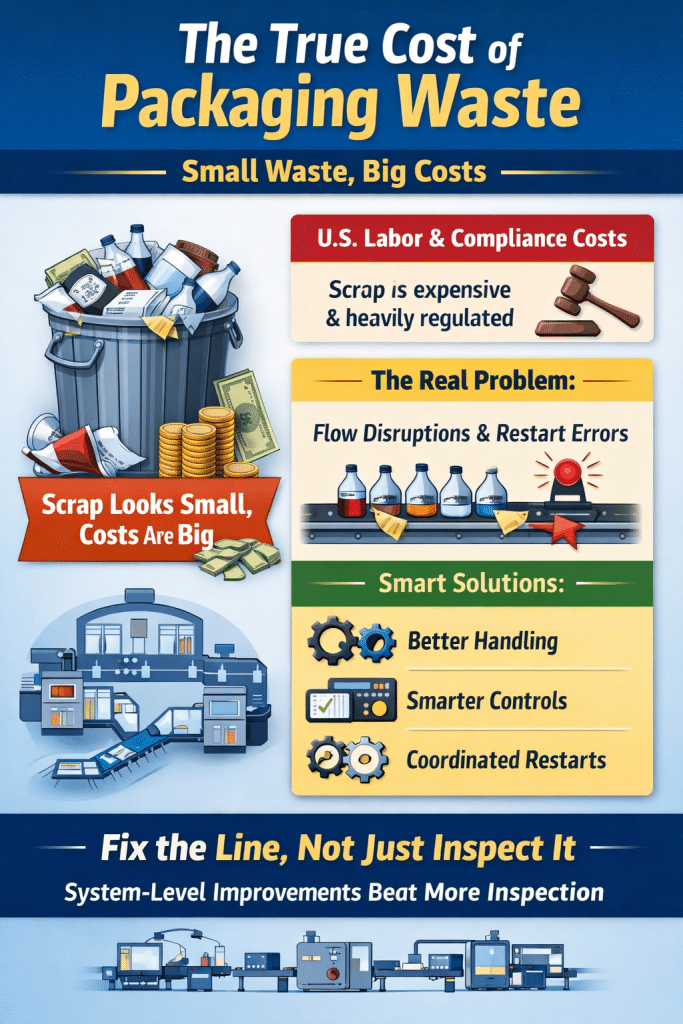

Key takeaways

- Packaging waste often looks small but carries big costs.

- U.S. labor and compliance rules magnify the impact of scrap.

- Most material loss comes from flow and restart problems, not bad materials.

- Better handling, smarter controls, and coordinated restarts cut waste.

- Fixing system behavior on packaging machines delivers more value than adding inspection.

For more details contact us:

| California | Texas | Florida |

|---|---|---|

| Address: 2980 Scott St, Vista, CA 92081 | Address: 8051 Jetstar Dr #175, Irving, TX 75063 | Address: 14231 Jetport Loop W #1, Fort Myers, FL 33913 |

| Phone: (760) 734-4177 | Phone: (972) 915-6888 | Phone: (239) 225-4020 |

| Fax: (760) 734-4188 | Fax: (971) 915-6999 | Fax: (239) 225-4024 |

| Hours: 8:00 AM – 4:30 PM | Hours: 8:00 AM – 4:30 PM | Hours: 8:00 AM – 4:30 PM |