For small to mid-size manufacturers like yours, getting labels spot-on is just as crucial as it is on those blazing-fast production lines. Those pesky misaligned labels, sneaky air bubbles, or uneven placements? They can ding your brand’s polish and even send good products back rejected. That’s where tabletop pressure sensitive labeling machine shine—they deliver pro-level results without the hefty space or price tag of full-auto systems.

In this buyer’s guide, we’ll walk you through how these handy machines work, what to look for when shopping, and why the Labelette APS-104 / SPS-104 has earned its spot as a go-to for labeling round bottles.

How Pressure Sensitive Labeling Works

Pressure sensitive labelers uses pre-cut labels with adhesive backing. Labels are applied directly to containers using rollers and guides, requiring no heat, glue, or drying time.

A typical tabletop pressure sensitive labeler includes:

- Label feed and peel plate

- Container rollers for smooth rotation

- Adjustable guides for alignment

- Simple controls for speed and placement

This method is especially effective for round bottles, where even rotation ensures straight, wrinkle-free label application.

Key Buying Criteria for Tabletop Round Bottle Labelers

Before choosing a machine, buyers should consider the following factors:

| Buying Factor | Why It Matters |

|---|---|

| Label Placement Accuracy | Ensures professional appearance and brand consistency |

| Bottle Size Range | Allows flexibility across different SKUs |

| Ease of Setup | Reduces downtime and operator error |

| Footprint & Portability | Important for small production spaces |

| Build Quality | Determines long-term reliability |

Machines designed only for speed often compromise accuracy, which defeats the purpose of pressure sensitive labeler.

Where the Labelette APS-104 / SPS-104 Fits in Buyer Evaluations

The Labelette tabletop pressure sensitive labeler, available as the APS-104 (electric) or SPS-104 (semi-automatic), is designed specifically for round bottles that require clean, precise label application.

Core strengths include:

- Accurate wrap-around labeling

- Smooth bottle rotation for even adhesive contact

- Quick adjustments for different bottle diameters

- Compact tabletop design for flexible placement

These features make the APS-104 / SPS-104 a popular choice for businesses that need reliability without complexity.

Key Features of the APS-104 / SPS-104

1. Precision Label Placement

- Consistent label alignment on cylindrical containers

- Reduces skewing, wrinkling, and bubbles

2. Wide Bottle Compatibility

- Handles a range of round bottle diameters

- Ideal for glass and plastic containers

3. Simple, Operator-Friendly Controls

- Minimal training required

- Faster setup and changeovers between products

4. Compact, Durable Construction

- Tabletop footprint saves valuable floor space

- Built for daily use in small production environments

Industries That Commonly Use Tabletop Round Bottle Labelers

The APS-104 / SPS-104 is widely used across industries that prioritize presentation and consistency:

- Food & Beverage: sauces, dressings, beverages, specialty foods

- Cosmetics & Personal Care: oils, serums, lotions

- Pharmaceuticals & Supplements: vitamins, syrups, liquid supplements

- Chemical Products: cleaners, solvents, specialty chemicals

For these industries, professional labeling is essential for compliance and brand trust.

How Buyers Compare Tabletop Pressure Sensitive Labelers

Buyers typically evaluate tabletop labelers based on:

- Labeling accuracy

- Ease of adjustment

- Consistency across batches

- Maintenance requirements

- Ability to scale with future needs

The APS-104 / SPS-104 performs well across these criteria because it balances simplicity with precision.

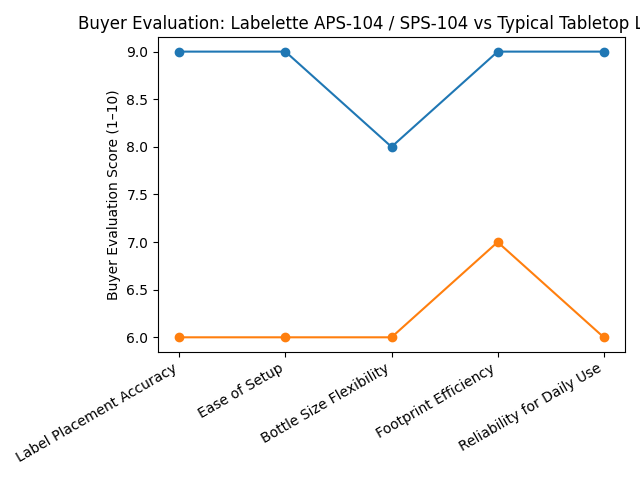

What This Buyer Evaluation Graph Shows

This graph reflects how buyers typically evaluate tabletop pressure sensitive labelers for round bottles when selecting equipment for small to mid-volume production.

Key insights for buyers:

- Label Placement Accuracy:

Consistent, straight label application is the top priority for round bottles. Systems with controlled bottle rotation score significantly higher. - Ease of Setup:

Faster adjustments and simple controls reduce downtime, especially for businesses running multiple SKUs. - Bottle Size Flexibility:

Buyers value machines that handle a range of bottle diameters without extensive reconfiguration. - Footprint Efficiency:

Compact tabletop designs are critical for facilities with limited floor space. - Reliability for Daily Use:

Durable construction becomes more important as production moves from occasional runs to daily operation.

The Labelette APS-104 / SPS-104 performs strongly across all criteria, making it a dependable choice for businesses that want professional labeling without moving to full inline automation.

Comparison: Labelette APS-104 / SPS-104 vs Typical Tabletop Labelers

| Feature | APS-104 / SPS-104 | Typical Tabletop Labeler |

|---|---|---|

| Label Accuracy | High, repeatable | Inconsistent |

| Bottle Stability | Smooth rotation | Limited control |

| Setup Time | Quick | Longer adjustments |

| Footprint | Compact tabletop | Varies |

| Long-Term Reliability | Industrial-grade | Light duty |

This comparison explains why many buyers choose the Labelette series when reliability matters.

Scalability and Line Integration

While designed as tabletop units, the APS-104 / SPS-104 can support growing operations by:

- Handling multiple SKUs on one machine

- Supporting small batch and contract labeling

- Serving as a stepping stone before inline automation

Many manufacturers start with tabletop labeling and upgrade later without sacrificing label quality early on.

A tabletop pressure sensitive labeler is often the smartest investment for businesses labeling round bottles at low to moderate volumes. The Labelette APS-104 / SPS-104 offers:

- Accurate, professional label application

- Simple operation with minimal training

- Compact design for space-limited facilities

- Reliable performance across multiple industries

For businesses seeking dependable labeling without unnecessary complexity, the APS-104 / SPS-104 remains a proven and practical choice.