Labeling machines are a critical link between production efficiency and brand presentation. Even minor inconsistencies in label application can result in waste, downtime, or diminished shelf appeal.

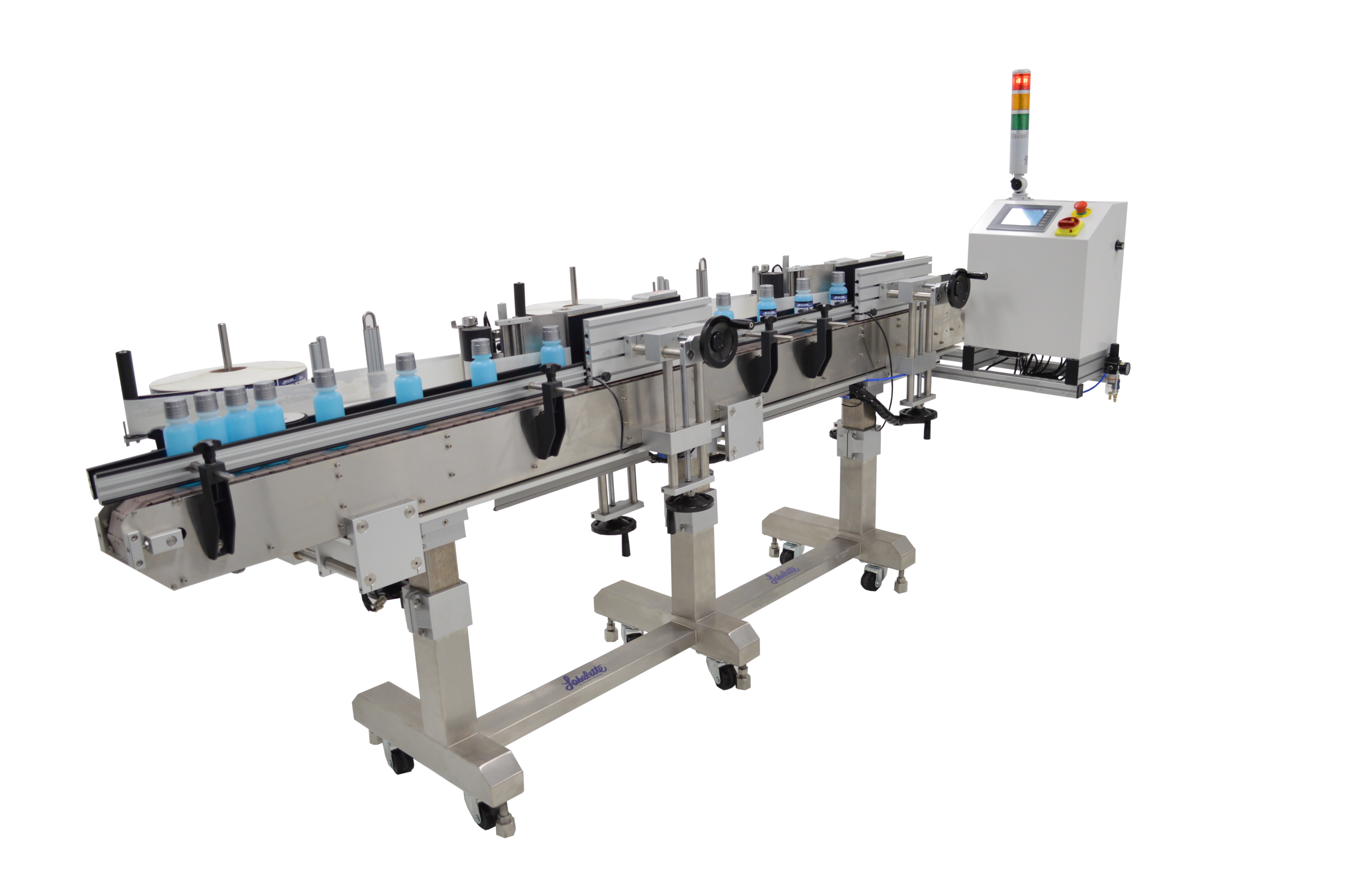

This article explores the most common labeling challenges faced by manufacturers and explains how the Accutek’s APS-206 Labeler addresses them through precision engineering and controlled operation.

Why Labeling Machine Issues Persist in Modern Packaging Lines

As production speeds increase and packaging formats diversify, labeling systems face growing demands. Many persistent issues stem from equipment limitations rather than operator error.

Common Contributing Factors

| Factor | Impact on Production |

|---|---|

| Inconsistent container flow | Label skewing and misalignment |

| Uneven label tension | Wrinkles or air bubbles |

| Limited adjustability | Slow changeovers |

| Mechanical wear | Declining accuracy over time |

Understanding these constraints is key to improving labeling machine performance.

Why Labeling Issues Persist in Modern Packaging Lines

As production speeds increase and packaging formats diversify, labeling systems face growing demands. Many persistent issues stem from equipment limitations rather than operator error.

Common Contributing Factors

| Factor | Impact on Production |

|---|---|

| Inconsistent container flow | Label skewing and misalignment |

| Uneven label tension | Wrinkles or air bubbles |

| Limited adjustability | Slow changeovers |

| Mechanical wear | Declining accuracy over time |

Understanding these constraints is key to improving labeling performance.

1. Misaligned or Crooked Labels

The Issue:

Labels applied off-center or at inconsistent angles negatively affect branding and can lead to product rejection.

How the APS-206 Solves It:

The APS-206 maintains precise container control and synchronized labeling motion to ensure consistent placement from unit to unit.

2. Label Wrinkling and Air Bubbles

The Issue:

Wrinkling often occurs when label tension is uneven or application pressure fluctuates.

How the APS-206 Solves It:

A controlled wrap mechanism ensures uniform pressure distribution, allowing labels to conform smoothly to the container surface.

3. Inconsistent Container Tracking

The Issue:

Container drift during labeling causes misalignment and production interruptions.

How the APS-206 Solves It:

Guided container paths and synchronized conveyors stabilize movement throughout the labeling cycle.

4. Slow or Inefficient Changeovers

The Issue:

Frequent SKU changes can create downtime and operator frustration.

How the APS-206 Solves It:

Adjustable components and repeatable settings enable faster, more predictable changeovers.

5. Performance Degradation Over Time

The Issue:

Wear and tear can reduce accuracy and reliability.

How the APS-206 Solves It:

Durable construction and serviceable components help maintain consistent performance across long production runs.

Operational Impact Summary

| Area of Operation | Impact with APS-206 |

|---|---|

| Label Accuracy | Consistent and repeatable |

| Line Efficiency | Reduced stoppages |

| Setup Time | Faster transitions |

| Maintenance | Predictable and manageable |

| Output Quality | Clean, professional finish |

Additional Performance Comparison

| Feature Area | Standard Labeler | APS-206 |

|---|---|---|

| Label placement consistency | Moderate | High |

| Changeover speed | Slow–Moderate | Fast |

| Container stability | Variable | Controlled |

| Long-term reliability | Inconsistent | Proven |

| Operator intervention | Frequent | Minimal |

Final Perspective

- Addresses the most common labeling failures found in production environments

- Improves consistency without adding operational complexity

- Supports higher throughput with stable, repeatable performance

- Reduces waste, rework, and downtime

- Integrates seamlessly into existing packaging lines

The Accutek APS-206 offers a practical, production-focused solution for manufacturers seeking dependable labeling machine performance without compromising efficiency or quality.