Labeling unstable cylindrical containers presents a unique challenge in modern packaging operations. Bottles that are tall, lightweight, or narrow often tip, wobble, or rotate inconsistently during labeling—leading to misalignment, label wrinkling, or production slowdowns.

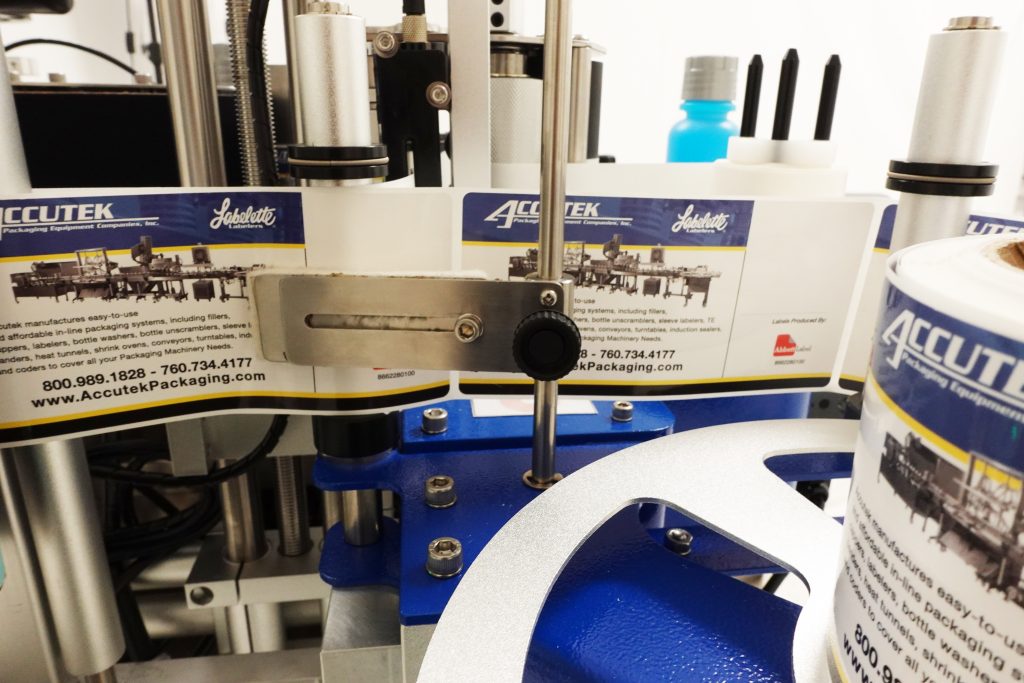

For these applications, a horizontal wrap labeling system is often the most effective solution. Among the systems used across U.S. production lines, the Accutek APS-134 Series is widely implemented for unstable cylindrical containers with precision and repeatability.

Why Unstable Cylindrical Containers Are Difficult to Label

Unlike rigid or wide-base containers, unstable cylindrical bottles create movement issues during label application. Common examples include:

- Slim cosmetic bottles

- Narrow pharmaceutical vials

- Small personal care containers

- Lightweight plastic tubes

When these containers are labeled upright, even minor vibration or conveyor movement can cause tipping or skewing, which directly impacts label accuracy.

Common Challenges

| Challenge | Impact on Production |

|---|---|

| Container tipping | Label misplacement |

| Irregular rotation | Wrinkled or skewed labels |

| Inconsistent bottle height | Misaligned wrap start/end |

| Manual stabilization | Reduced throughput |

These challenges make traditional vertical labeling systems inefficient for unstable containers.

What a Horizontal Wrap Labeling Machine Does Differently

A horizontal wrap labeling machine positions containers on their side during labeling, fully supporting the container along its length. This eliminates instability and ensures consistent rotation throughout the labeling process.

Key functional advantages include:

- Controlled container movement

- Even label tension during wrap

- Reduced reliance on gravity for stability

- Improved alignment consistency

The Accutek APS-134 Series is engineered specifically for this type of application.

Overview of the Accutek APS-134 Series

The APS-134 is a horizontal pressure-sensitive labeling system designed for cylindrical containers that cannot remain stable in an upright position.

Core Capabilities of the APS-134

| Feature | Description |

|---|---|

| Label orientation | Horizontal wrap-around |

| Container handling | Cradle-supported rotation |

| Label application | Pressure-sensitive |

| Changeover | Adjustable guides and tooling |

| Production flow | Continuous and controlled |

This configuration allows labeling of containers that would otherwise require manual handling or secondary operations.

Applications That Benefit from Horizontal Labeler

The APS-134 is commonly used in industries where container stability is limited:

| Industry | Typical Products |

|---|---|

| Cosmetics | Serums, slim lotion bottles |

| Personal care | Roll-ons, gels |

| Pharmaceuticals | Small-diameter vials |

| Specialty chemicals | Narrow cylindrical bottles |

By maintaining horizontal support, label placement remains consistent even at higher production speeds.

Integration Within a Packaging Line

The APS-134 is designed to operate as part of a broader packaging system.

Typical Line Integration

| Packaging Stage | Equipment Type |

|---|---|

| Filling | Piston or peristaltic fillers |

| Capping | Chuck or spindle cappers |

| Labeling | APS-134 horizontal labeler |

| Outfeed | Accumulation tables or conveyors |

This modular compatibility allows manufacturers to expand production capacity without reconfiguring their entire line.

Operational Advantages of Horizontal Labeler

Compared to vertical systems, horizontal labeler offers measurable operational benefits:

| Operational Area | Vertical Labeler | APS-134 Horizontal Labeler |

|---|---|---|

| Container stability | Moderate | High |

| Label alignment | Variable | Consistent |

| Operator intervention | Frequent | Minimal |

| Throughput reliability | Inconsistent | Stable |

These advantages make horizontal systems ideal for precision-driven packaging environments.

Why Manufacturers Choose Accutek’s APS-134 Platform

Manufacturers select Accutek’s APS-134 not for marketing appeal, but for functional reliability:

- Designed for unstable or narrow containers

- Proven performance in cosmetic and pharmaceutical environments

- Compatible with automated packaging lines

- Supported by U.S.-based engineering and service teams

This makes the APS-134 a dependable solution for operations that require accuracy without compromising efficiency.

Final Perspective

When labeling unstable cylindrical containers, equipment choice directly affects product presentation, efficiency, and consistency. Accutek’s APS-134 Series provides a practical solution by stabilizing containers horizontally and applying labels with controlled precision.

For manufacturers working with narrow or lightweight containers, a horizontal wrap labeling system is not a convenience — it is a necessity.