For manufacturers operating high-speed production lines, capping is not a minor step—it is a critical control point that affects product integrity, safety, and compliance. An unreliable capping system can lead to leaks, recalls, downtime, and customer dissatisfaction. This is why selecting the right automatic spindle capper is a key investment decision for growing operations.

This guide explains how automatic spindle cappers work, what buyers should evaluate, and why many U.S. manufacturers ultimately choose the Accutek ASC Series for scalable, long-term production.

Why High-Speed Production Lines Require Automatic Spindle Capping

As production volumes increase, manual and semi-automatic capping solutions quickly reach their limits. High-speed lines require capping systems that can operate continuously while maintaining consistent torque and container stability.

Automatic spindle cappers are designed to:

- Apply caps at high speeds without sacrificing seal quality

- Maintain repeatable torque across every container

- Reduce labor dependency and operator error

- Integrate seamlessly with filling and labeling equipment

For manufacturers planning to scale, spindle capping is not optional—it is foundational.

How Automatic Spindle Cappers Work

Automatic spindle cappers use rotating spindle wheels to apply and tighten caps as containers move through the system. Each spindle can be adjusted to control torque, ensuring caps are applied securely without damaging closures or containers.

Core components typically include:

- Adjustable spindle heads

- Container side belts for stability

- Cap delivery and placement systems

- Integrated conveyors and controls

This design allows spindle cappers to handle a wide variety of cap styles, container shapes, and production speeds.

Key Buying Criteria for Automatic Spindle Cappers

Before selecting a machine, buyers should evaluate the following factors carefully:

| Buying Factor | Why It Matters |

|---|---|

| Line Speed Capacity | Determines whether the machine can support current and future production volumes |

| Torque Control Accuracy | Prevents leaks, recalls, and damaged caps |

| Cap & Container Flexibility | Reduces the need for multiple machines |

| Integration Capability | Ensures smooth operation with fillers and labelers |

| Build Quality & Durability | Supports multi-shift, long-term operation |

Machines optimized only for speed often sacrifice torque consistency or stability—leading to costly downstream issues.

Where the Accutek ASC Series Fits in Buyer Evaluations

The Accutek ASC Series Automatic Spindle Capper is designed for manufacturers who need balanced performance, not just high output. Rather than functioning as a standalone unit, the ASC Series is engineered to operate as part of a complete packaging line.

Key capabilities include:

- High-speed capping without compromising seal integrity

- Individually adjustable spindle torque

- Support for multiple cap types and container formats

- Heavy-duty construction for continuous use

- Seamless integration with filling and labeling systems

This makes the ASC Series especially attractive for operations planning long-term growth.

Industries That Benefit Most from Automatic Spindle Capping

Automatic spindle cappers are widely used across industries where seal reliability and throughput are critical:

- Food & Beverage: sauces, dressings, beverages, condiments

- Pharmaceuticals: syrups, OTC liquids, regulated products

- Cosmetics & Personal Care: lotions, creams, shampoos

- Chemicals: cleaners, lubricants, industrial fluids

In these industries, inconsistent capping can quickly become a compliance and safety issue.

How Buyers Compare Leading Spindle Capping Solutions

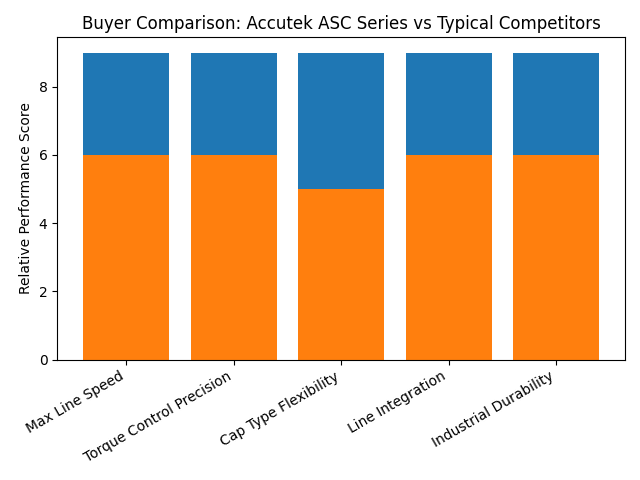

Below is a visual comparison highlighting what buyers value most when evaluating spindle cappers for high-speed production.

This graph reflects how manufacturers typically evaluate automatic spindle cappers for high-speed production lines during the purchasing process.

What This Buyer Evaluation Graph Demonstrates

Key insights from the graph:

- Torque Consistency:

Buyers prioritize consistent torque application to prevent leaks, recalls, and cap damage. Systems with individual spindle control score significantly higher. - High-Speed Stability:

Maintaining container alignment and cap accuracy at higher speeds is more important than raw output alone. - Cap Type Flexibility:

Manufacturers prefer machines that support multiple cap sizes and styles to reduce future equipment purchases. - Line Integration:

Packaging lines perform best when cappers are designed to integrate seamlessly with fillers, labelers, and conveyors. - Long-Term Durability:

Industrial-grade construction becomes increasingly important as production scales to multi-shift operations.

Accutek Packaging Equipment Company, Inc. scores higher across all major evaluation criteria, making it a strong long-term investment for manufacturers planning growth.

What the Comparison Shows

- Buyers prioritize torque precision and stability, not speed alone

- Machines designed for integration outperform standalone units long term

- Industrial durability matters more as production scales

The Accutek ASC Series consistently performs well across all major evaluation criteria.

Comparison: Accutek ASC Series vs Typical Competitors

| Feature | Accutek ASC Series | Typical Competitor |

|---|---|---|

| Supported Line Speed | High-speed capable | Moderate |

| Torque Adjustability | Individual spindle control | Limited |

| Cap Type Support | Wide range | Narrow |

| Integration Readiness | Full packaging line | Often standalone |

| Long-Term Durability | Industrial-grade | Light to medium duty |

This comparison highlights why many manufacturers upgrade to Accutek as production demands increase.

Turnkey Packaging Line Compatibility

One of the ASC Series’ strongest advantages is its ability to integrate into turnkey packaging systems, including:

- Automatic filling machines

- Labeling machines

- Conveyors and accumulation tables

This allows manufacturers to expand capacity without replacing core equipment—protecting their investment over time.

Choosing the right automatic spindle capper is about more than speed. For manufacturers operating high-speed production lines, the ideal system must deliver:

- Consistent, repeatable torque

- Stability at higher line speeds

- Flexibility across caps and containers

- Industrial durability for continuous operation

- Seamless integration into complete packaging lines

The Accutek ASC Series meets these requirements, making it a trusted choice for U.S. manufacturers across food, pharmaceutical, cosmetic, and chemical industries.