High-gloss glass bottles are a hallmark of premium branding across cosmetics, personal care, and specialty beverage markets. However, their polished surfaces also make them highly vulnerable to scuffing, scratching, and surface abrasion during labeling.

Preventing these defects requires more than slower speeds or operator adjustments — it requires equipment engineered for controlled contact and stability. This is where the Accutek APS-106-F Labeler plays a critical role.

Why High-Gloss Glass Bottles Are Especially Vulnerable

Unlike textured or coated containers, high-gloss glass reflects light and magnifies even the smallest imperfections. During labeling, these bottles face multiple friction points that can compromise appearance.

Common Causes of Scuffing During Labeling

| Cause | Resulting Issue |

|---|---|

| Bottle-to-bottle contact | Visible scratches and rub marks |

| Excessive side pressure | Dulling of glossy finish |

| Inconsistent spacing | Edge collisions |

| Abrupt acceleration or stops | Micro-abrasions |

| Rigid guide rails | Surface marring |

These issues are amplified in high-speed environments where precision and control are essential.

Why Traditional Labeling Systems Often Fall Short

Many standard wrap labeling systems are designed for throughput rather than surface preservation. While effective for durable containers, they often lack the fine control needed for high-gloss glass.

Common limitations include:

- Rigid mechanical guides with minimal adjustability

- Uneven pressure during label wrap

- Limited control over container rotation

- Excess friction at transfer points

This can lead to cosmetic defects even when labels are applied accurately.

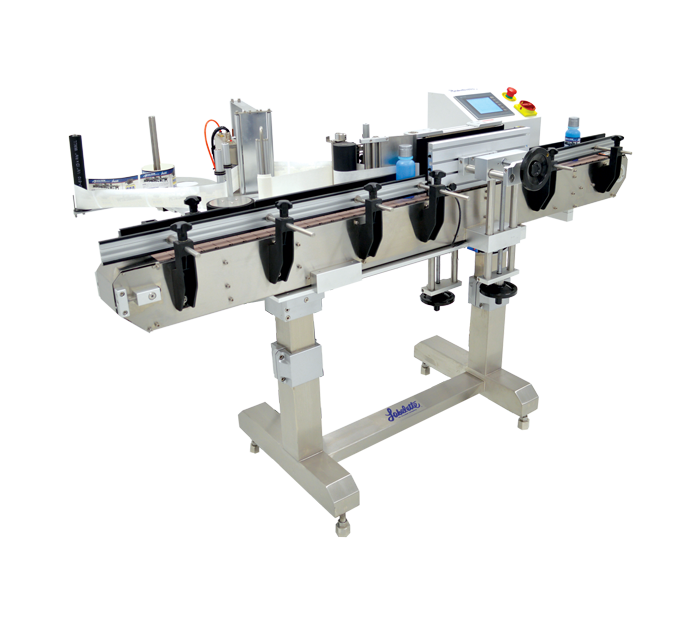

The Role of the Accutek APS-106-F Labeler

The APS-106-F is engineered to address these exact challenges by emphasizing stable transport, controlled contact, and smooth label application.

Rather than forcing containers through aggressive mechanical paths, the APS-106-F maintains consistent positioning while minimizing surface interaction.

Design Features That Help Prevent Scuffing

Controlled Container Handling

| Feature | Function |

|---|---|

| Precision spacing control | Prevents bottle contact |

| Smooth conveyor transitions | Reduces vibration and abrasion |

| Adjustable guide rails | Maintains alignment without pressure |

| Stable bottle rotation | Ensures even label wrap |

Gentle Label Application

| Feature | Benefit |

|---|---|

| Balanced wrap tension | Prevents surface drag |

| Controlled label dispense | Eliminates snap-back contact |

| Consistent rotational speed | Reduces micro-friction |

These elements work together to protect high-gloss finishes throughout the labeling process.

Applications Where the APS-106-F Excels

The APS-106-F is commonly used for products where visual quality is non-negotiable:

| Industry | Example Products |

|---|---|

| Cosmetics | Serums, fragrances, lotions |

| Beverage | Premium spirits, glass bottled drinks |

| Personal care | Oils, shampoos, conditioners |

| Specialty food | Sauces, infused oils |

Integration Within a Packaging Line

The APS-106-F is designed to integrate seamlessly with upstream and downstream equipment, ensuring stable bottle flow throughout production.

Typical Packaging Line Configuration

| Stage | Equipment |

|---|---|

| Filling | Gravity or piston fillers |

| Capping | Chuck or spindle cappers |

| Labeling | APS-106-F |

| Accumulation | Rotary or inline tables |

This integration supports consistent labeling without introducing surface damage.

Operational Benefits of Using the APS-106-F

| Benefit | Operational Impact |

|---|---|

| Reduced cosmetic defects | Higher product acceptance |

| Fewer rejected units | Improved yield |

| Consistent labeling quality | Stronger brand presentation |

| Lower rework and inspection | Increased efficiency |

Operational Benefits of Using the APS-106-F

| Benefit | Operational Impact |

|---|---|

| Reduced cosmetic defects | Higher product acceptance |

| Fewer rejected units | Improved yield |

| Consistent labeling quality | Stronger brand presentation |

| Lower rework and inspection | Increased efficiency |

Why Manufacturers Choose the APS-106-F

Manufacturers select the APS-106-F because it provides:

- Controlled handling for delicate containers

- Proven performance in premium packaging environments

- Compatibility with automated production lines

- Long-term reliability supported by U.S.-based engineering

It delivers consistency without sacrificing throughput.

Final Perspective

When labeling high-gloss glass bottles, maintaining surface integrity is just as important as label accuracy. The Accutek APS-106-F Labeler supports this requirement by providing controlled, repeatable labeling conditions designed for premium packaging environments.

Key takeaways include:

- Designed to minimize surface contact and reduce the risk of scuffing or abrasion

- Maintains consistent bottle positioning throughout the labeling process

- Supports high-gloss and premium glass finishes without compromising appearance

- Integrates smoothly into automated packaging lines

- Helps maintain production efficiency while protecting product presentation

For manufacturers handling high-value glass containers, the APS-106-F offers a balanced solution that prioritizes both labeling precision and surface protection, making it well-suited for demanding packaging environments.