Sustainability is a modern business imperative, and today’s manufacturers are under increasing pressure from consumers to produce products that have sustainability in mind.

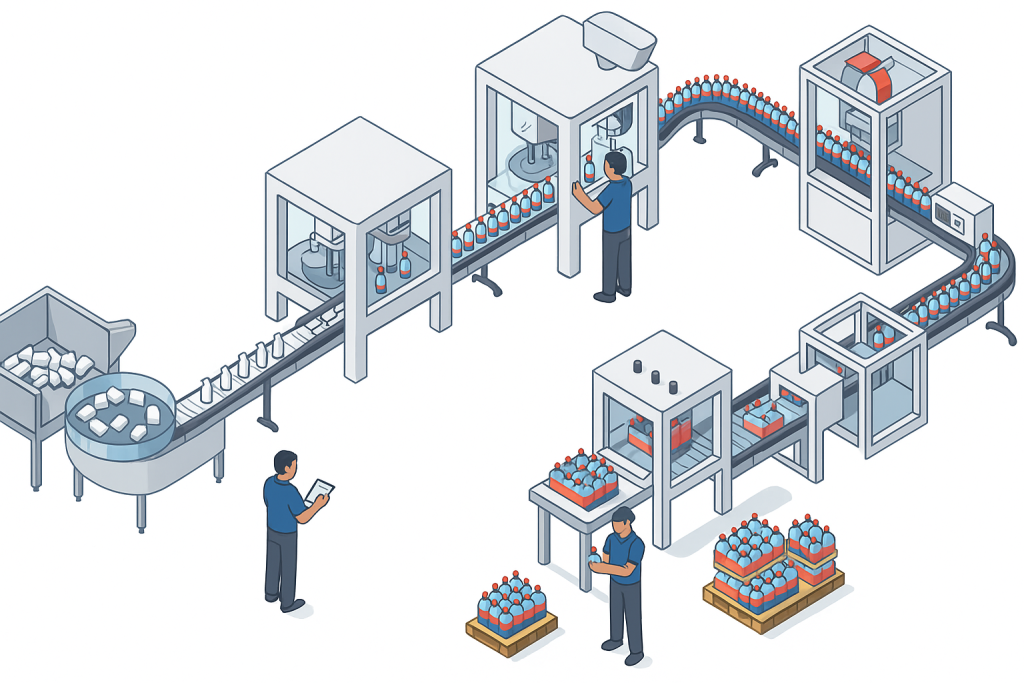

One area where major progress is being made is in packaging automation. Modern packaging machines are helping companies achieve greener, more efficient operations without sacrificing productivity.

At Accutek Packaging Machine & Equipment, we’ve seen firsthand how advanced packaging technology can make manufacturing cleaner, leaner, and more sustainable.

Reducing Material Waste Through Precision

A significant contributor to waste in packaging operations is overfilling. Even slight inconsistencies in fill volume can lead to wasted product and packaging materials. That’s where precision automation makes a noticeable difference.

Modern filling machines use advanced flowmeters, servo motors, and sensor-based feedback systems to deliver accurate and consistent fill levels. This precision minimizes product waste, reduces the need for oversized containers, and ensures that each unit meets exact specifications.

By using only what’s necessary, you save on both materials and product loss, and reduce downstream waste. The result is a leaner operation that consumes fewer resources and generates less landfill waste.

Energy Efficiency in Modern Packaging Machines

Variable speed drives and power-saving modes match energy usage to production demand. For manufacturers, this means lower electricity bills and a smaller carbon footprint. Over time, these savings compound, creating a more sustainable and cost-effective packaging process.

Supporting Recyclable and Eco-Friendly Packaging Materials

Another major step toward sustainability comes from the shift to eco-friendly packaging materials such as lightweight plastics, recycled paperboard, and biodegradable films. However, these materials can behave differently from traditional options and require specialized handling.

Accutek’s packaging machines are built to accommodate a wide variety of container types and materials without compromising performance. Whether you’re using thinner plastics, compostable films, or glass alternatives, our equipment provides the flexibility and precision needed to ensure consistent results.

By making it easier to adopt recyclable materials, modern filling and capping machines help manufacturers meet sustainability goals while maintaining the high-quality packaging consumers expect.

How CIP Systems Contribute to Sustainability

Maintaining your equipment also helps to boost sustainability. Nowadays, many filling machines are equipped with clean-in-place (or CIP) systems that reduce water and chemical consumption during sanitation cycles. These automatic cleaning processes use targeted rinsing and recirculation techniques to cut down on waste while still maintaining the utmost standards of hygiene.

CIP conserves valuable resources and cuts down on both operating costs and downtime, boosting both environmental and financial efficiency.

Sustainability That Strengthens Your Business

Sustainability is good for the planet and for business. Consumers are increasingly choosing brands that demonstrate sustainability. So by investing in efficient, precision-engineered packaging machines, you can lower costs, reduce emissions, and build stronger relationships with your eco-conscious customers.

Build a Greener Future with Accutek

The path to a more sustainable future starts by making smarter manufacturing decisions. By integrating advanced packaging machines into your production line, you can achieve measurable improvements in efficiency and environmental responsibility. And you won’t have to compromise on quality or on speed.

Contact Accutek Packaging Equipment today to learn how our filling and capping machines can help your business package more sustainably and operate more efficiently.