Alcohol-based products place unique demands on packaging machinery. Unlike water-based liquids, alcohol formulations introduce challenges related to flammability, vapor management, material compatibility, and regulatory compliance. From hand sanitizers and disinfectants to spirits, extracts, and industrial alcohols, packaging lines must be engineered to handle volatility without sacrificing throughput, accuracy, or operator safety.

For California manufacturers operating under strict safety and workplace regulations, packaging machine design is not just a performance decision—it is a compliance requirement.

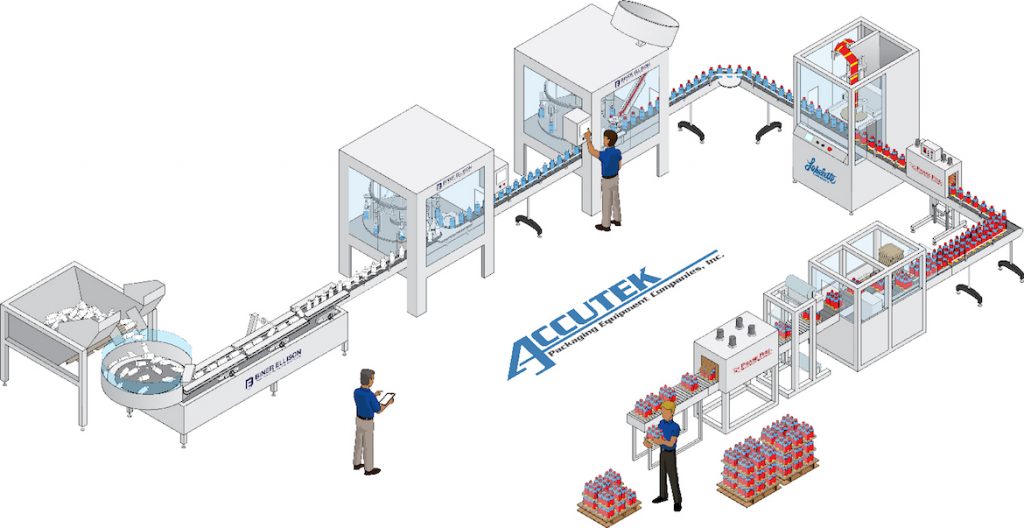

This article explains how packaging machinery must be engineered for alcohol-based products and highlights Accutek Packaging Equipment Company, Inc. solutions that are purpose-built for these demanding applications.

Why Alcohol-Based Products Require Specialized Packaging Machinery

Alcohol behaves differently than most liquid products on a packaging line. Its low viscosity, high evaporation rate, and flammability amplify risks that standard machines are not designed to manage.

Key engineering challenges include:

- Flammable vapor generation during filling

- Static electricity buildup

- Seal degradation from solvent exposure

- Foaming during high-speed filling

- Strict OSHA, NFPA, and local safety requirements

Packaging machinery for alcohol-based products must therefore integrate mechanical precision, material science, and safety engineering into a unified system.

Filling Machine Design for Alcohol-Based Liquids

Alcohol-based products are typically low-viscosity, fast-flowing liquids, which makes volumetric control and splash prevention critical.

Engineering Requirements

- Smooth, controlled liquid flow to prevent turbulence

- Alcohol-compatible seals, gaskets, and tubing

- Enclosed or guarded fill zones to manage vapor

- Optional explosion-proof components for high-alcohol environments

Accutek Filling Machines Used for Alcohol-Based Products

Timed Flow Volumetric Fillers

Ideal for low-viscosity alcohol products such as sanitizers, disinfectants, and ethanol solutions. These systems deliver consistent fill volumes while minimizing splash and foaming.

Overflow Fillers

Commonly used for alcohol bottles where cosmetic fill level consistency is critical, such as spirits and clear consumer products.

Piston Fillers (Configured for Alcohol)

While piston fillers are often associated with thicker products, Accutek configures stainless steel piston systems with alcohol-resistant seals for controlled filling where accuracy is critical.

All Accutek fillers for alcohol applications can be built with:

- 316 stainless steel contact parts

- Alcohol-resistant elastomers

- Optional ATEX-ready or explosion-proof electrical configurations

Managing Safety and Compliance in Alcohol Packaging Lines

Alcohol packaging is governed by overlapping safety frameworks that influence machine design.

Key Standards Affecting Packaging Machinery

- OSHA flammable liquid handling requirements

- NFPA guidelines for ignition prevention

- California workplace safety and fire codes

- Electrical classification for hazardous environments

Packaging Machinery Design Considerations

- Grounding and bonding to prevent static discharge

- Enclosed motors and electrical components

- Proper ventilation around filling and capping zones

- Emergency stop and interlock systems

Accutek designs packaging machinery with safety-first engineering, allowing California manufacturers to meet operational and regulatory expectations without sacrificing productivity.

Capping Machine Engineering for Alcohol-Based Products

Alcohol products often use caps that must withstand vapor pressure, prevent evaporation, and maintain seal integrity over time.

Engineering Challenges

- Vapor pressure buildup in sealed containers

- Cap material compatibility with alcohol

- Torque consistency to prevent leaks

Accutek Capping Solutions

- Automatic Spindle Cappers for high-speed alcohol bottling lines

- Servo-controlled capping systems for precise torque application

- Integration with retorquers where seal validation is required

These systems ensure consistent sealing while protecting against evaporation and leakage during storage and transport.

Labeling Machine Considerations for Alcohol Packaging

Alcohol exposure can degrade adhesives and label materials if not properly engineered.

Labeling Challenges

- Adhesive breakdown from alcohol vapor

- Condensation during filling

- High-speed label placement on glass and plastic bottles

Accutek Labeling Machines for Alcohol Products

- Pressure-Sensitive Labeling Machines with alcohol-resistant adhesive compatibility

- Wrap labeling systems designed for glass spirits bottles

- Integrated wipe-down stations to ensure label adhesion

Proper labeling machine selection prevents label failure while maintaining compliance with branding and regulatory labeling requirements.

Labeling Machine Considerations for Alcohol Packaging

Alcohol exposure can degrade adhesives and label materials if not properly engineered.

Labeling Challenges

- Adhesive breakdown from alcohol vapor

- Condensation during filling

- High-speed label placement on glass and plastic bottles

Accutek Labeling Machines for Alcohol Products

- Pressure-Sensitive Labeling Machines with alcohol-resistant adhesive compatibility

- Wrap labeling systems designed for glass spirits bottles

- Integrated wipe-down stations to ensure label adhesion

Proper labeling machine selection prevents label failure while maintaining compliance with branding and regulatory labeling requirements.

Why California Manufacturers Choose Accutek for Alcohol Packaging

Accutek Packaging Equipment Company, Inc. supports alcohol-based product manufacturers with:

- Proven filling machine designs for low-viscosity liquids

- Packaging machinery configured for flammable environments

- U.S.-based engineering and compliance support

- Customizable solutions without experimental risk

- Long-term service and parts availability

For manufacturers packaging alcohol-based products in California, reliability, safety, and engineering integrity are non-negotiable. Accutek delivers packaging machinery designed to meet those demands.

Key Takeaways for Alcohol-Based Product Packaging

- Alcohol-based products require specialized packaging machine design

- Filling machines must control flow, minimize vapor, and resist solvent exposure

- Packaging machinery must align with safety and compliance standards

- Accutek offers proven filling, capping, and labeling solutions for alcohol products

- Engineering-driven system integration reduces risk and increases uptime