The visual appeal of a product is very important for it to have a lasting effect on the consumer. When you see anything displayed on the shelves of a shop, the first thing that drives your attention toward a product is its appealing label. A good labelling machine is important because it will make your products’ labels catchy and attractive. Labelling machines are vital for the smooth functioning of industries as they employ novel techniques and help save tons of time and money.

In this blog, we’ll explore one of the most noteworthy types of labelling machines, i.e., hot glue labelling machine, which has been making waves in diverse industries due to its high efficiency and versatility.

What are Hot glue labelling machines?

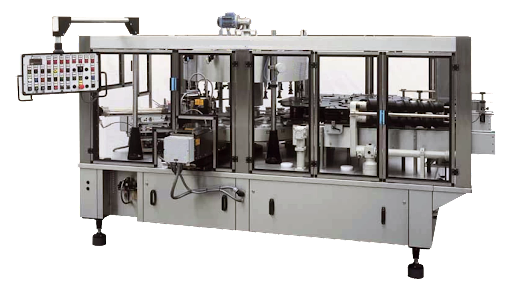

Hot glue labelling machines, also known as hot glue machines or hot melt glue labelers, are industrial devices that are designed to apply labels to packaging or products with the help of a hot melt adhesive. Hot glue machines are widely used in industries such as food and beverages, pharmaceuticals, cosmetics, and other manufacturing and industrial sectors where precise and secure labelling is essential. The process of hot glue labelling offers a solid and reliable way to affix labels to different types of product surfaces.

How do hot glue labelling machines work?

Here is a detailed explanation of hot glue machines’ critical components and functionalities:

1. Label Roll and Unwind System:

Label rolls are the first thing that hot glue labelling machines use. The label roll is fed into the device, and the unwind mechanism makes a regulated label release possible. This technology guarantees a steady supply of labels for labelling and avoids label jams.

2. Label Dispensing and Cutting:

One label at a time is fed into the labelling machine. A cutting mechanism detaches the label from the roll, while a dispensing system regulates the exact release of each label. This guarantees that the product labels are placed accurately.

3. Hot Melt Glue System:

The hot melt glue system is the key component of the hot glue labelling process. Thermoplastic adhesives, such as hot melt glue, are heated inside the machine to a molten state. Pellets or sticks can be used as the glue.

4. Label Application Mechanism:

The product or package that has been labeled is fed through a labelling station, where the label is attached accurately with hot melt adhesive.

5. Pressure and Timing Controls:

Hot glue labelling machines include controls for varying the pressure and timing of label application. These variables can be adjusted Depending on the labels’ features and the kind of labeled goods or containers.

6. Cooling and Setting Station:

Once the label is placed, the branded product may go through a cooling or setting station. This makes it possible for the hot melt glue to set and guarantees that the label and the product’s or package’s surface will be firmly bonded.

7. Quality Control and Inspection:

For quality assurance, some hot glue labelling machines have cameras or sensors built in. These technologies are able to identify flaws such as missing or misaligned labels. The uniformity and quality of items with labels are preserved with automated examination.

Advantages of hot glue labelling machines

Now that we know how a hot glue labelling machine functions, we’ll explore the benefits of making it a must-have across varied industries.

- Precise Label Application: Hot glue labelling machines ensure error-free labelling on containers. They allow business to meet their packaging demands effectively and efficiently.

- High Efficiency: Hot glue labelling machines can put around 1200 labels per minute, significantly boosting production rates and increasing efficiency.

- Versatility: Such labelers can work with various container sizes and shapes, allowing businesses to serve multiple production lines without maximizing costs.

- Easy setup and changeover: These labelling machines are easy to set up and change, reducing downtime when switching between different container types and sizes.

- Durability: Hot glue labelling machines are durable, easy to maintain, and cost-effective.

Diverse application of hot glue labelling machines:

Hot glue labelling machines find diverse applications across various industries due to their versatility, efficiency, and reliability. Here are some notable examples of their varied applications:

1. Food and Beverage Industry:

Hot glue labelling machines are extensively used in the food and beverage sector for labelling bottles, jars, cans, and other packaging containers. They are suitable for different packaging materials and help maintain label integrity even in environments with temperature variations.

2. Pharmaceuticals and Healthcare:

Hot glue labelers are crucial for accurately labelling medicine bottles, boxes, and packaging in the pharmaceutical industry. The secure bond provided by hot melt glue ensures that important product information and safety details remain intact throughout the distribution process.

3. Cosmetics and Personal Care Products:

The cosmetics industry uses hot glue labelling machines to label beauty and personal care products. These machines offer precise and attractive label applications, from shampoo bottles to cosmetic packaging.

4. Home and Cleaning Products:

Products such as cleaning agents, detergents, and household items often require durable labelling. Hot glue labelers are suitable for these applications, ensuring labels stay in place even in environments prone to moisture and handling.

5. Automotive and Chemical Industries:

Hot glue labelling machines provide a reliable solution for labelling containers and parts in industries dealing with chemicals and automotive products. The robust adhesive properties of hot melt glue make it ideal for withstanding harsh conditions.

6. Electronics and Technology:

Hot glue labelers label electronic components, gadgets, and technology products. The precision and accuracy of these machines are essential for maintaining product aesthetics and conveying important information to consumers.

7. Logistics and Shipping:

Hot glue labelling machines are used to label packaging boxes and parcels in logistics and shipping. The durability of hot melt glue ensures that labels remain intact during transportation, even in varying environmental conditions.

8. Pet Food and Agriculture:

Hot glue labelers are used to label pet food packaging and agricultural products. The strong adhesive properties make them ideal for labelling bags and containers exposed to outdoor elements.

The diverse applications of hot glue labelling machines highlight their adaptability to various industries and products.

How can we prolong the functioning of hot glue labelling machines?

Prolonging the functioning of hot glue labelling machines requires regular maintenance, proper operation, and adherence to best practices. Here are some tips to help extend the lifespan and efficiency of hot glue labelling machines:

1. Regular Cleaning:

Keeping the machine clean by regularly removing dust, debris, and adhesive residue will add to the machine’s longevity. Pay attention to the labelling and gluing components, as any buildup can affect performance. Follow the manufacturer’s guidelines for cleaning procedures.

2. Proper Lubrication:

Ensure that all moving parts are well-lubricated according to the manufacturer’s recommendations. Regular lubrication prevents friction, reduces wear and tear, and improves the machine’s smooth operation.

3. Monitor and Adjust Temperature Settings:

Hot glue labelling machines rely on precise temperature control for the hot melt glue. Regularly check and calibrate the temperature settings to ensure optimal performance. Avoid overheating, as this can lead to glue degradation and other issues.

4. Use High-Quality Glue Sticks:

Choose high-quality hot melt glue sticks or pellets recommended by the machine’s manufacturer. Using inferior or incompatible adhesives can lead to clogs, uneven application, and other problems.

5. Inspect and Replace Parts:

Periodically inspect the machine for worn or damaged parts such as rollers, belts, and cutting blades. Replace any components showing signs of wear to prevent breakdowns and maintain consistent labelling quality.

6. Calibration and Adjustment:

Regularly calibrate and adjust the machine settings for label placement, pressure, and timing. This ensures accurate and consistent labelling, reducing the likelihood of misalignments or application errors.

7. Employee Training:

Train machine operators thoroughly to ensure they understand the proper operation, maintenance, and troubleshooting procedures. Well-trained operators are more likely to identify and address issues before they escalate.

Final Thoughts

Machinery manufacturers like Accutek packaging equipment Company, Inc. deliver high-quality and user-friendly packaging and labelling machines that meet the varied needs of our customers and increase their productivity and efficiency. Investing in reliable labelling machines is crucial for minimizing operational costs and maximizing results.

Accutek ensures that customers are offered exceptional customer support at competitive prices and fosters product innovation.